Cylinder cleaning agent for high-temperature dye-jigger and application thereof

A technology for cleaning jiggers and cylinders, which is applied to cleaning methods and utensils, detergent compositions, detergent compounding agents, etc., which can solve the problems of large usage, achieve excellent effects, excellent cleaning effects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

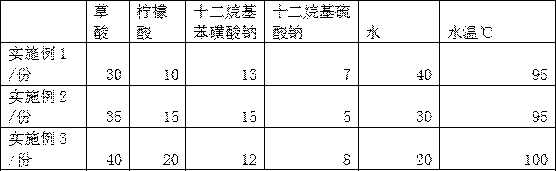

[0023] A tank cleaning agent for a high-temperature dyeing machine, comprising the following components: oxalic acid, citric acid, sodium dodecylbenzenesulfonate, sodium dodecylsulfate and water. See Table 1 for specific ratios.

[0024] Add the high-temperature jigger tank cleaning agent in the tank of the dyeing jigger, the addition amount is 5kg per 100L of water, and heat it at 100°C for 8 hours; after cleaning the tank, it can be directly dyed and produced after washing with hot water in the tank. cut costs.

[0025] Table 1. Specific ratio

[0026]

[0027] Through the neutralization reaction, it will not corrode the cylinder body, the cleaning effect is good, and the application performance is excellent; the tank cleaning agent is acidic, and the effect is good when used alone, and it does not need to be used with other additives; compared with conventional pickling and hydrosulfite. , The effect of cleaning the scale of the machine tank is extremely excellent. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com