Canal lining concrete in-situ casting method and non-linear canal lining construction method

A construction method and concrete technology, applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems that the local position of the channel lining cannot be vibrated and firm, the quality and aesthetics of the channel project are affected, and the channel lining structure is not dense enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

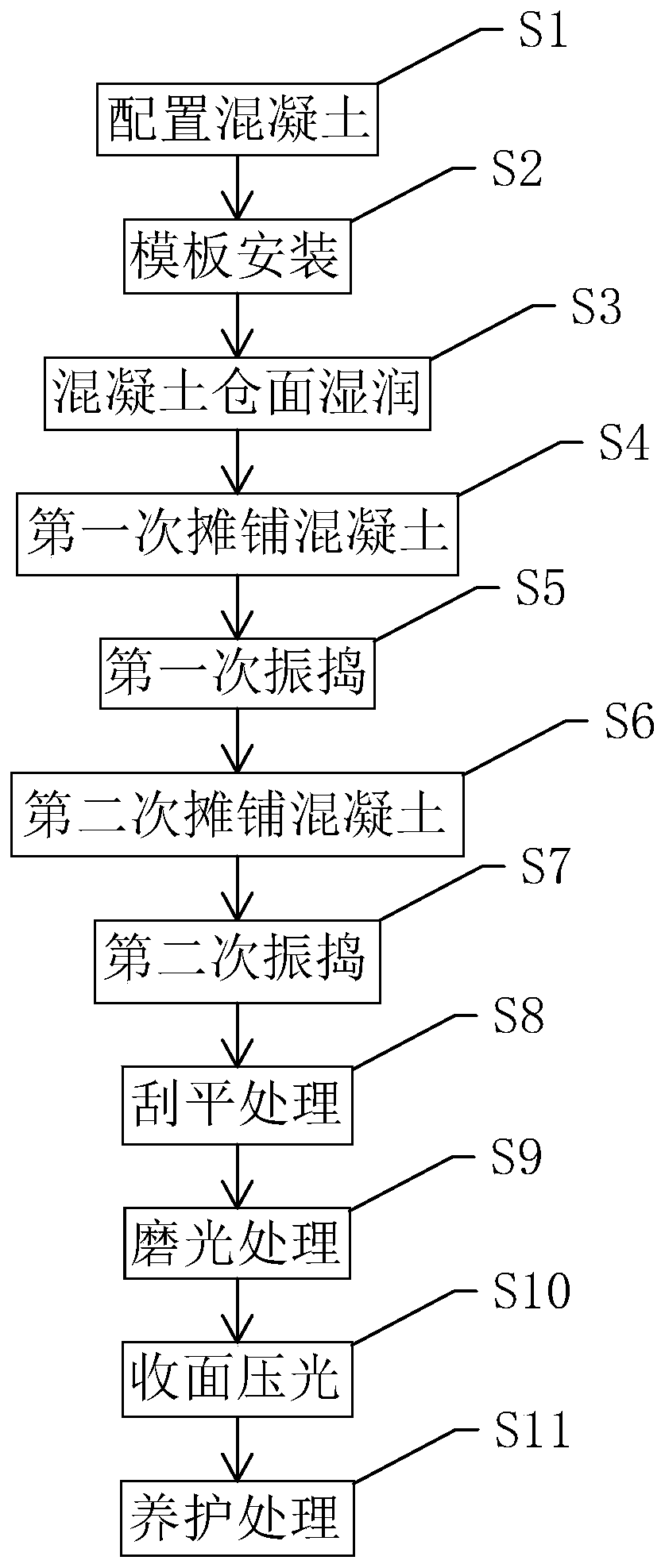

[0056] refer to figure 1 and figure 2 , is a kind of channel lining concrete cast-in-place method disclosed by the present invention, comprising the following steps: configuring concrete S1, formwork installation S2, concrete warehouse surface wetting S3, first paving concrete S4, first vibrating S5, second Second paving concrete S6, second vibrating S7, scraping treatment S8, polishing treatment S9, surface finishing and calendering S10, and curing treatment S11.

[0057] Concrete configuration S1: The raw materials of the following mass parts of concrete are prepared: 50-60 parts of water, 90-110 parts of cement, 390-400 parts of sand, 360-380 parts of pebbles, 2-4 parts of admixture, the slump of concrete Between 100-150 mm, the water-binder ratio of concrete is between 0.50-0.60, and the sand ratio of concrete is 50.0%-53.0%. The concrete of the above formula has high structural strength after curing, is not easy to seepage, and has a long service life, thereby prolongi...

Embodiment 2

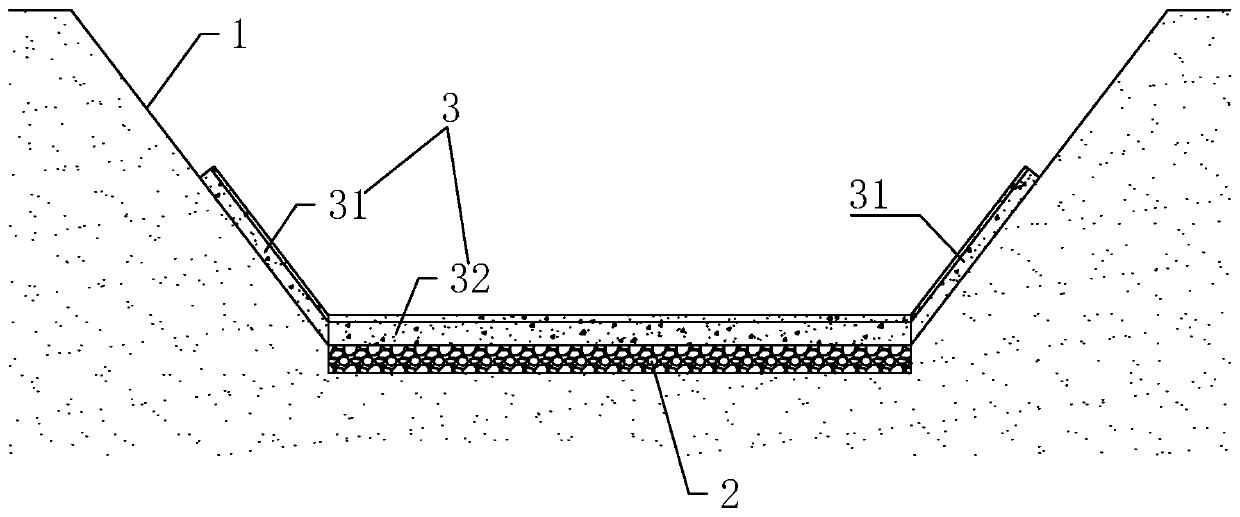

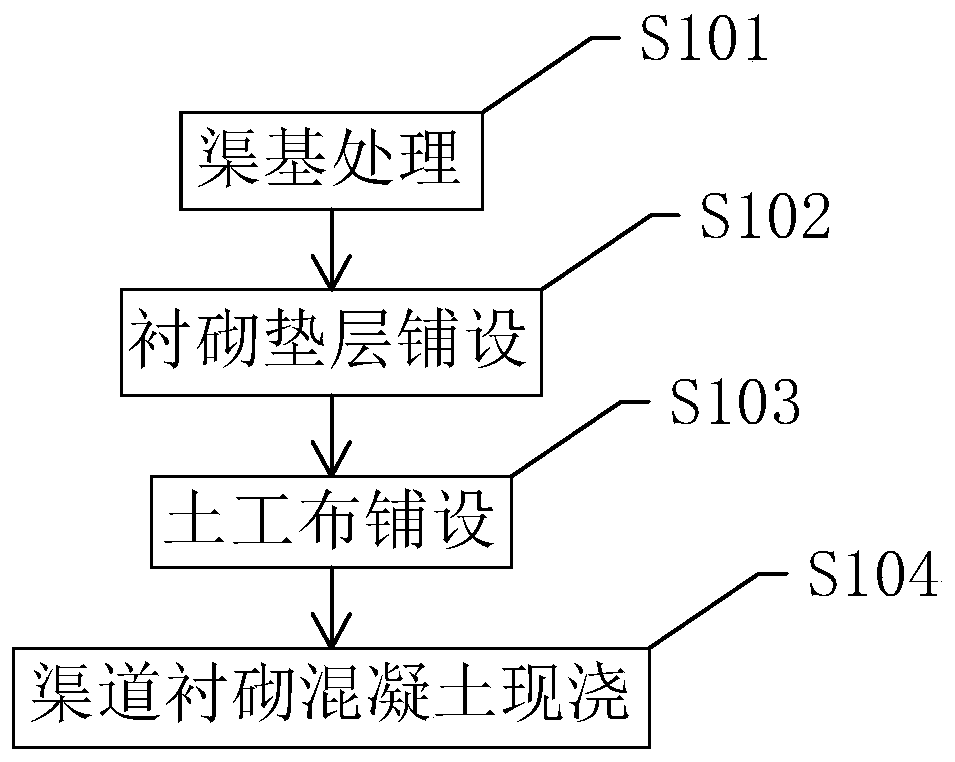

[0075] refer to figure 2 and image 3 , is a non-linear canal lining construction method disclosed in the present invention, the canal includes a linear area and a curved area, the canal lining 3 includes: a slope surface lining 31 and a bottom surface lining 32, and the channel lining 3 in a linear area adopts The block-by-block method of construction is adopted, and the channel lining 3 in the curved area is constructed by the method of pouring through the warehouse.

[0076] Based on the channel lining concrete casting method as described in Embodiment 1, the non-linear channel lining construction method includes: canal foundation treatment S101: remove the bad soil and garbage on the surface of the canal foundation 1, and the pits on the surface of the canal foundation 1 Fill and compact with backfill soil, the compaction degree of the backfill soil is not less than 0.92; laying the lining cushion S102: Lay the sandstone cushion 2 on the bottom surface of the canal found...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com