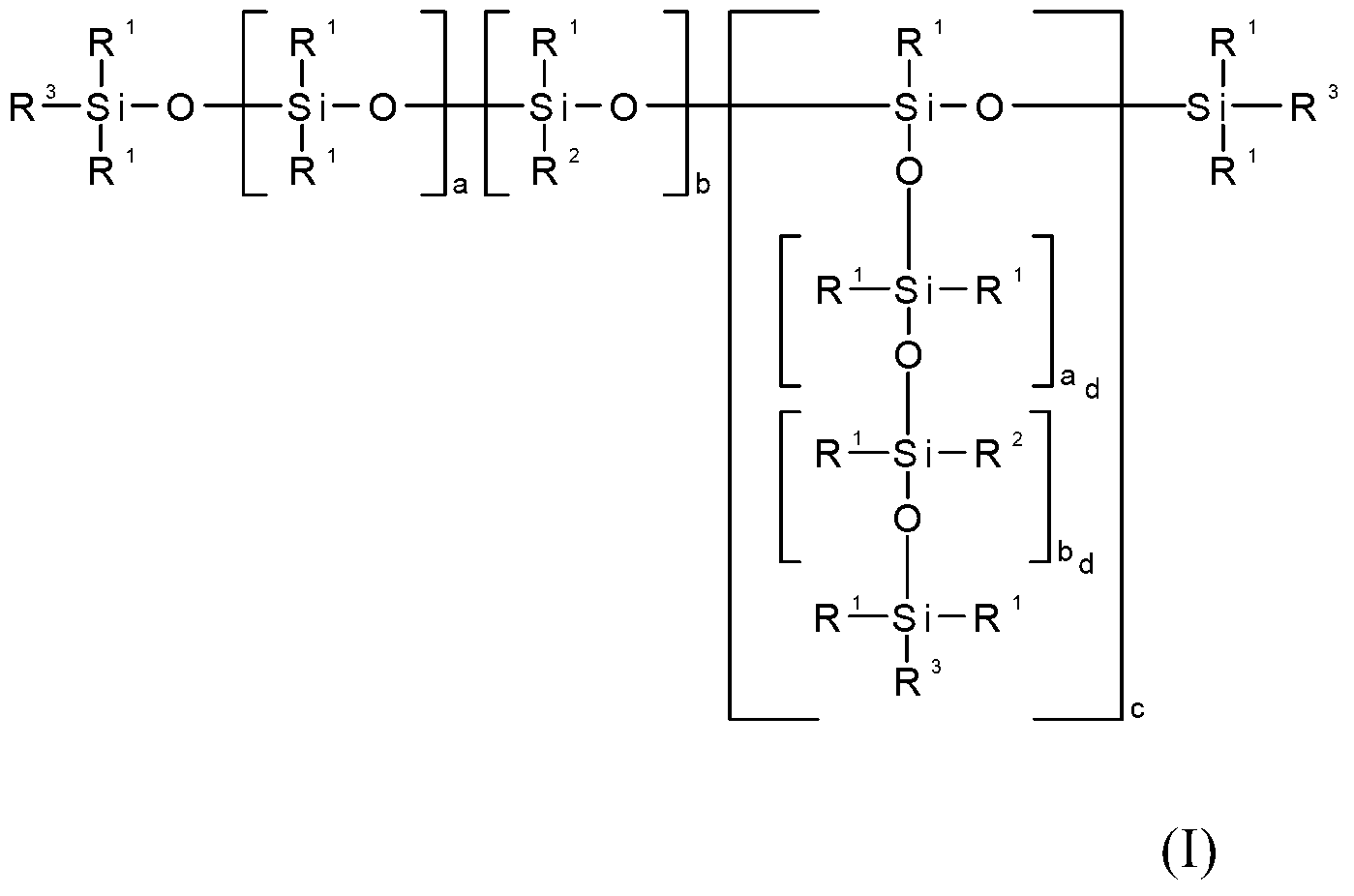

Use of silicone methacrylate particles in cosmetic formulations

A technology of polysiloxane methacrylate and cosmetic composition, which is applied in the field of application of polysiloxane methacrylate particles in cosmetic formulations, and can solve the problem of affecting the stability of compositions and formulations, high cost and other issues to achieve the effect of high stability and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

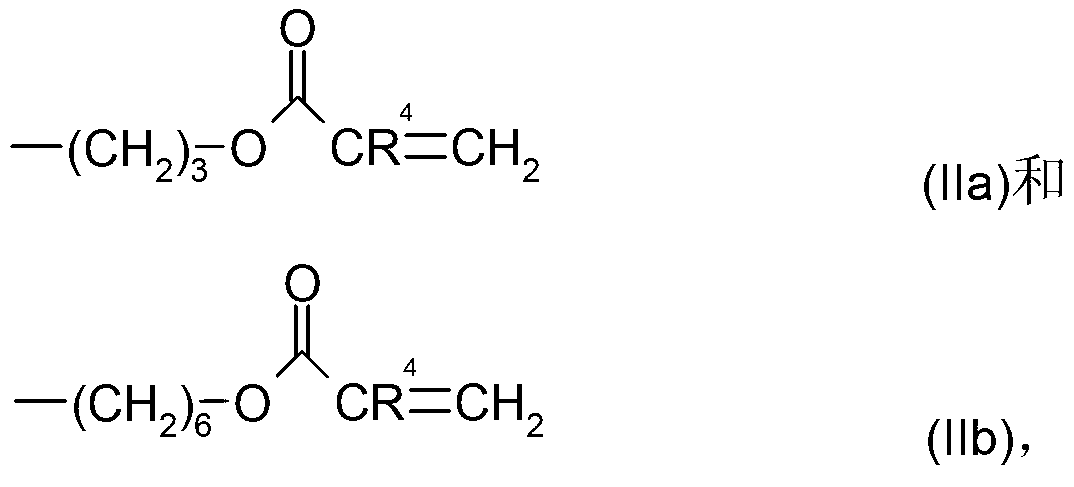

Method used

Image

Examples

Embodiment 1

[0091] Example 1: Polysiloxane Methacrylate Particles

[0092] 588.5 g of dipotassium hydrogen phosphate was dissolved in 550 g of deionized water. Mix 2600g of deionized water and 115g of Ludox SM mixed and adjusted to pH=7. With stirring, 1100 g of polysiloxane methacrylate (described in patent document DE 3810140) are added and the mixture is pre-emulsified for a few minutes. Then, under stirring, add 27.5 g of 5% strength VARISOFT PATC in water, and the mixture was pre-emulsified again for a few minutes. The mixture produced in this way was then homogenized at 300 bar using a homogenizer of the Microfluidizer type from Microfludics with an interaction chamber with a diameter of 200 μm.

[0093] For polymerization, the emulsion was placed in a round-bottomed flask and heated to 80°C with stirring, purging with nitrogen. First, 153 g of ammonium peroxodisulfate dissolved in 500 g of deionized water were added, followed by 93.87 g of a 38% strength sodium bisulfite sol...

Embodiment 2 and comparative example C2

[0095] The formulations given in Table 1 were prepared and their stability, appearance and skin feel were evaluated.

[0096] Table 1: Formulations and results of Example 2 and Comparative Example C2 oil-in-water care cream

[0097]

Embodiment 3 and comparative example C3

[0098] Example 3 and Comparative Example C3: Oil-in-Water Body Lotion Prepared Under Cold Conditions

[0099] The formulations given in Table 2 were prepared and their stability, appearance and skin feel were evaluated.

[0100] Table 2: Formulation and results of the oil-in-water body lotion prepared under cold conditions in Example 3:

[0101]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com