Integrated multi-degree-of-freedom rigid-flexible coupling motion platform driven by ball screw

A ball screw and rigid-flexible coupling technology, applied in the field of motion platforms, can solve problems such as flexible hinge deformation, large consumables, and tipping, and achieve the effects of preventing deformation in non-working directions, increasing work reliability, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

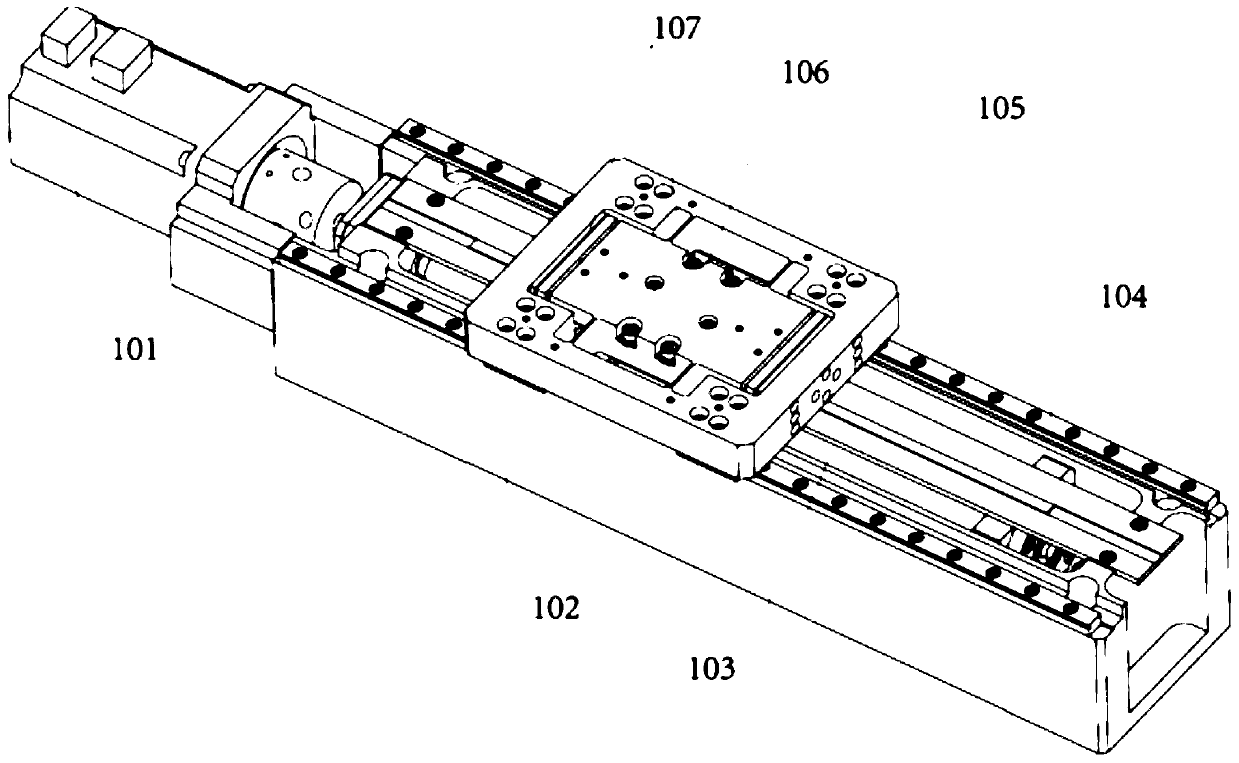

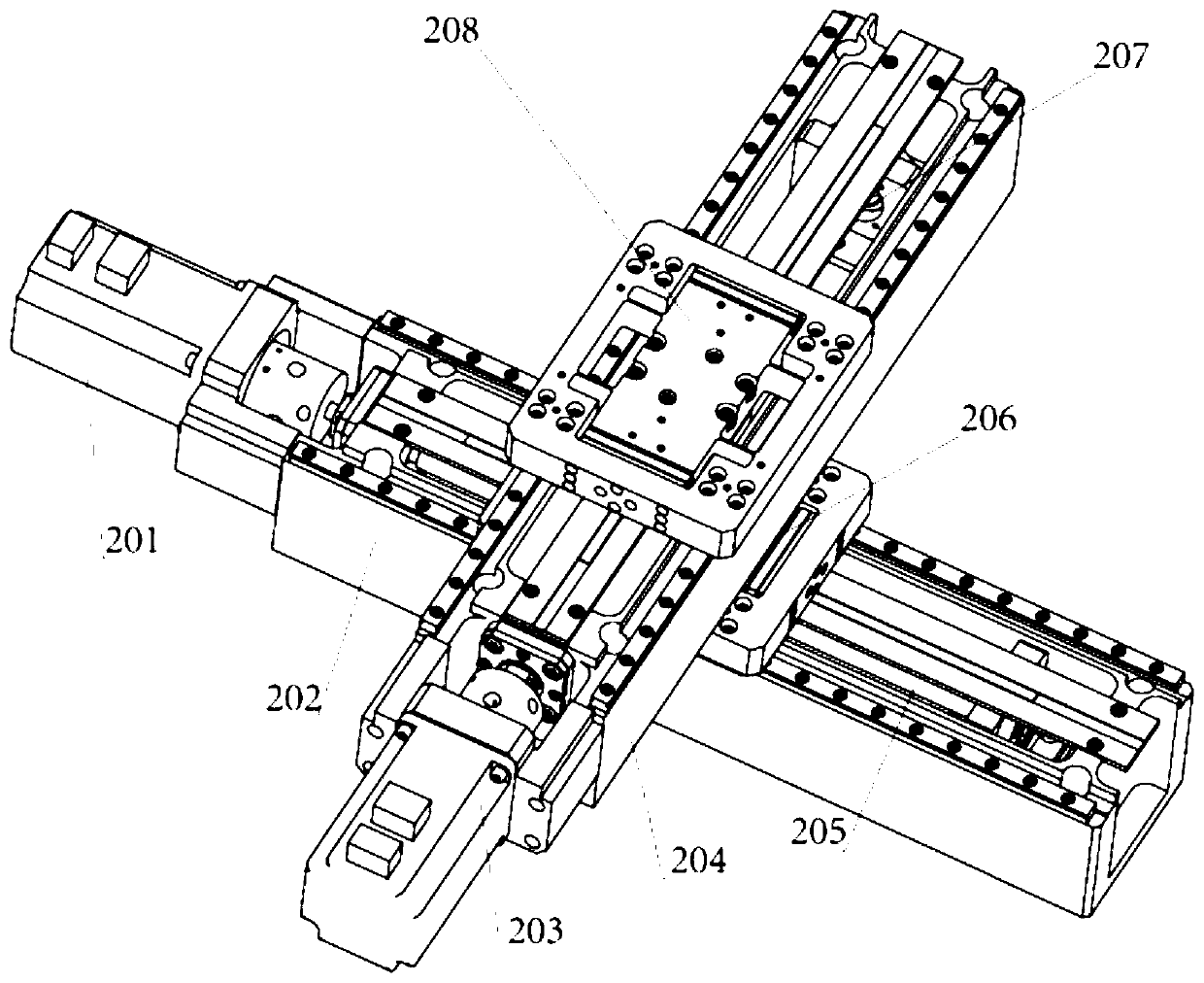

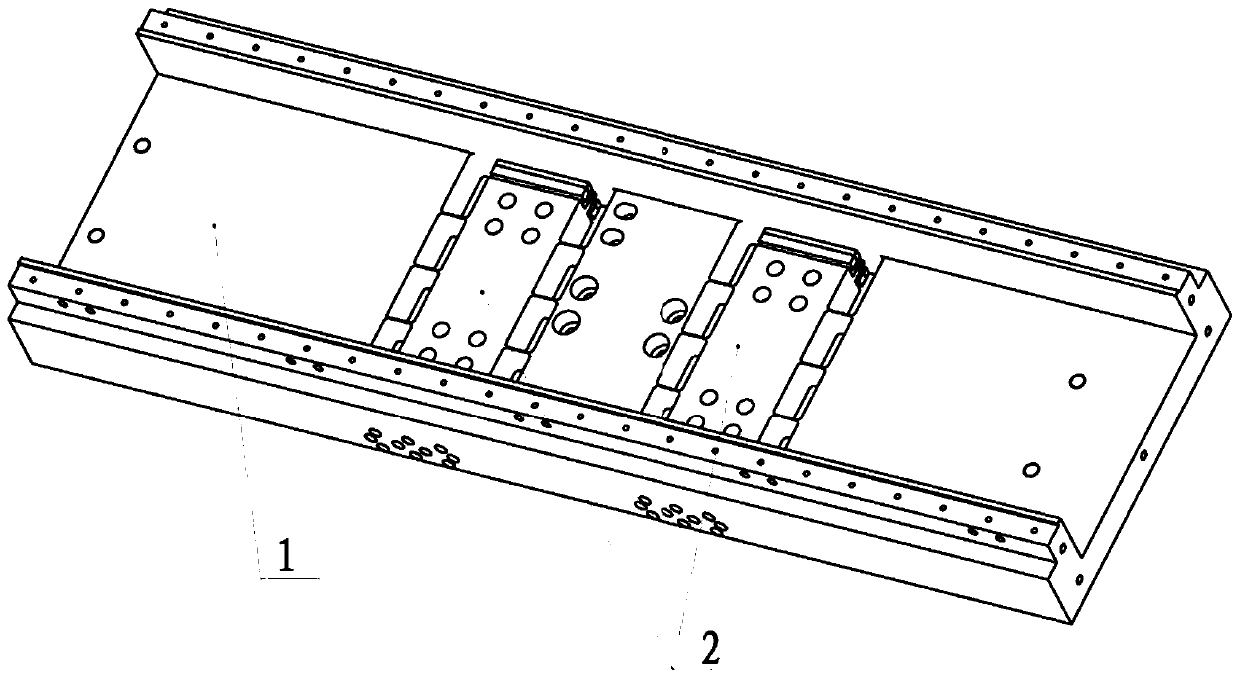

[0040] refer to Figure 3 to Figure 10, this embodiment relates to an integrated multi-degree-of-freedom rigid-flexible coupled motion platform driven by a ball screw, including an X-axis frame 1 and a first flexible hinge platform 2 , the X-axis frame 1 is connected to the Y-axis frame 3 The Y-axis drive device of the frame 3 At the power output end of 31, the Y-axis drive device 31 drives the X-axis frame 1 to slide along the Y-axis direction. The side of the first flexible hinge platform 2 in the X-axis direction is connected to the X-axis frame 1 through the flexible hinge 4. The The side of the first flexible hinge platform 2 in the Y-axis direction is mounted on the X-axis frame 1 through the spring-plate flexible hinge 5; the first flexible hinge platform 2 is provided on each guide rail of the Y-axis guide mechanism, and the guide rail is isolated The influence of friction; the first flexible hinge platform 2 is mounted on the Y-axis frame 3 through the guide mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com