Brush box of brush motor and torsion spring anti-falling structure

A technology with a brushed motor and an anti-separation structure, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of the motor not running, detached from the carbon brush, and detached, and achieve the effect of ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

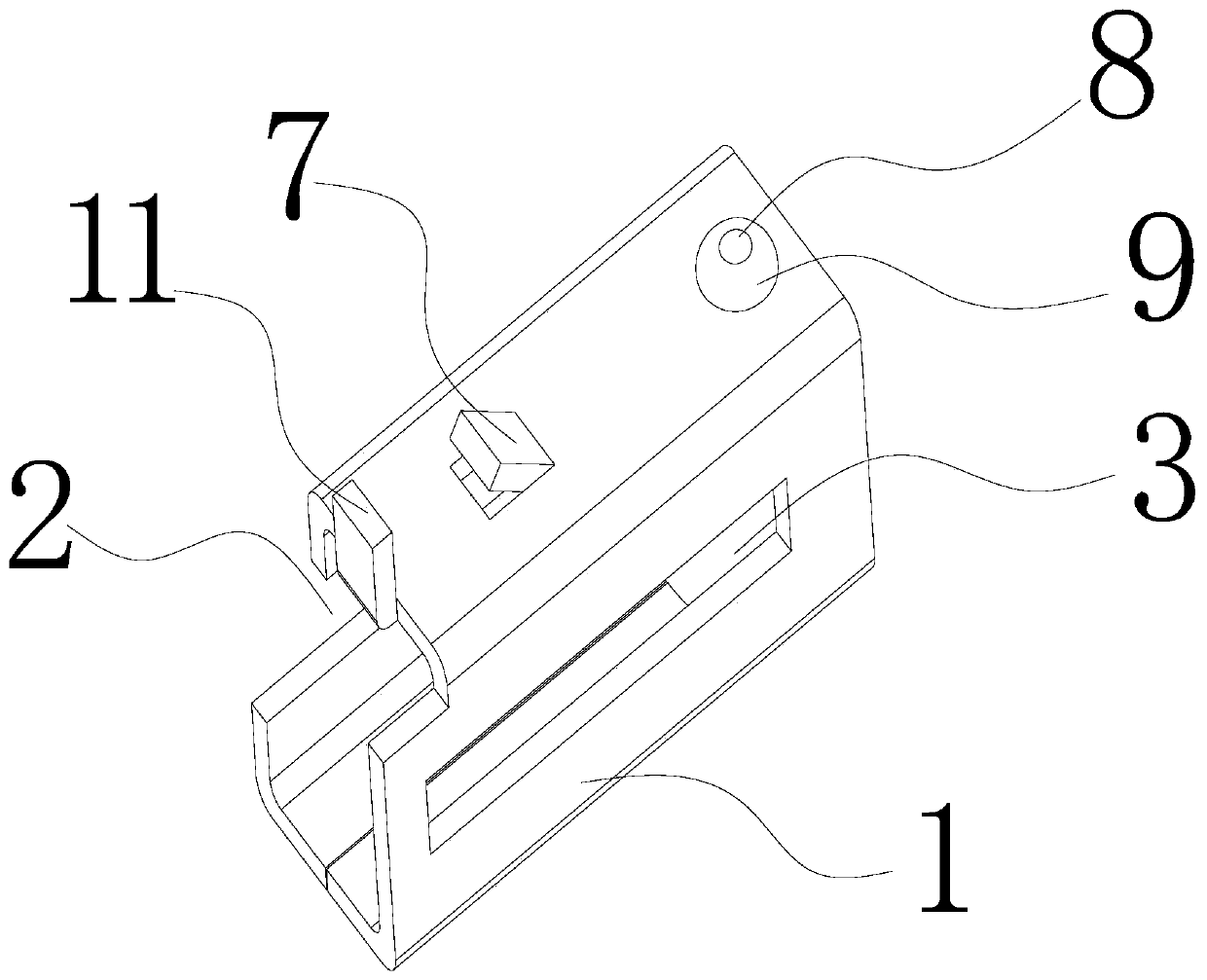

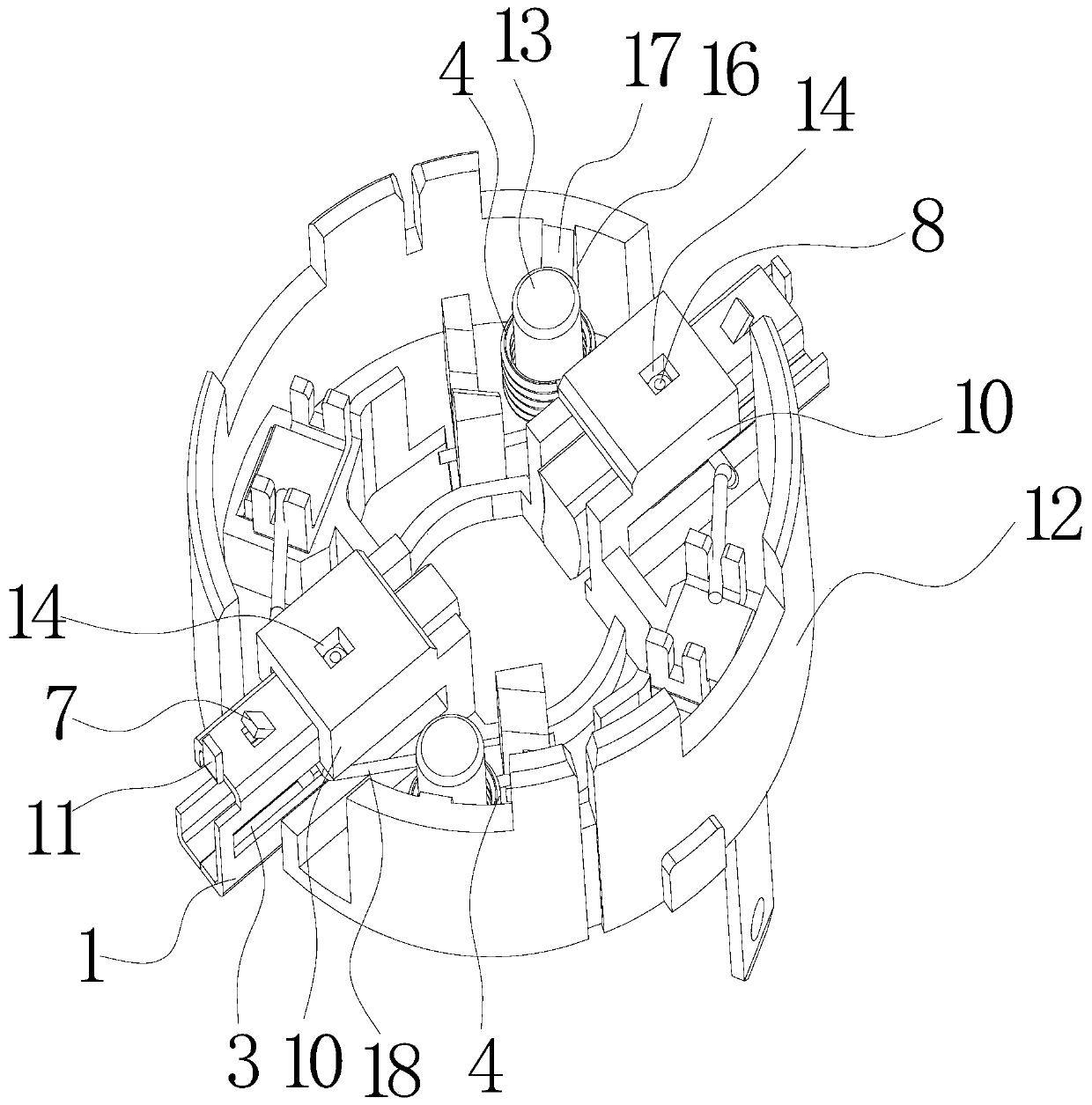

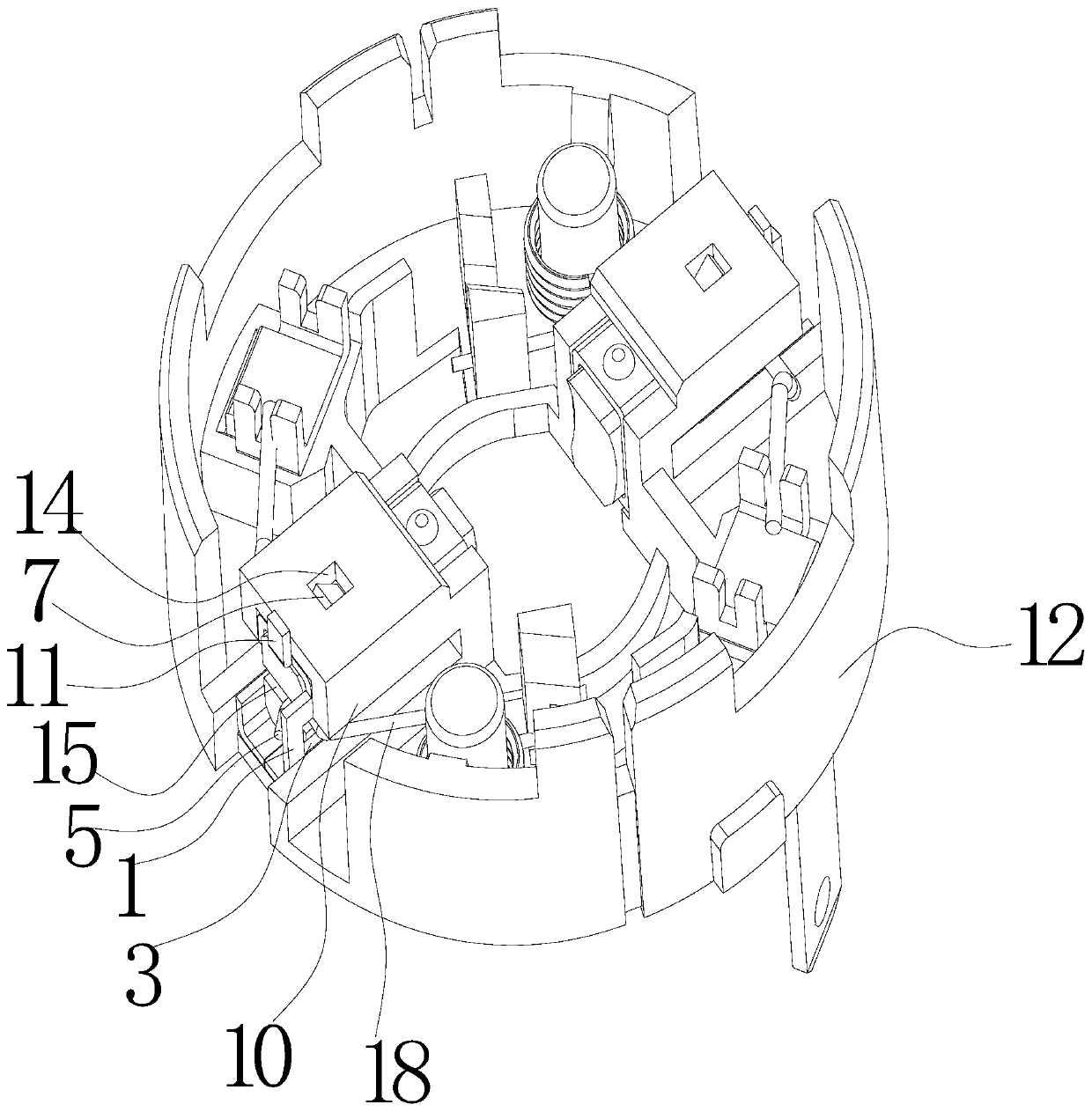

[0027] Such as figure 1 , figure 2 and image 3 As shown, this embodiment provides a brush box 1 with a brush motor. One side of the brush box is provided with a slot 2, and the other side is provided with a closed slot 3. In this embodiment, the slot is a U-shaped slot. , the closed groove is a square groove, and the closed groove is used for the hook pin 5 of the torsion spring 4 to pass through and abut against the carbon brush 6. By changing the slot on one side of the brush box to a closed groove, the brush box to the torsion spring can be realized. Limit position, after the motor is assembled, the torsion spring will not come out due to the impact of falling, so as to ensure the normal operation of the motor. The top surface of the brush box is provided with a shrapnel 7 and a boss 8, and the side of the boss is an arc-shaped guide surface 9. The shrapnel and the boss are located on the same straight line, and the shrapnel and the boss can be embedded in the brush box...

Embodiment 2

[0029] Such as figure 2 and image 3 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment provides a torsion spring anti-off structure for a brushed motor including the above-mentioned brush box, including a middle plate 12, carbon brushes, a brush box and a torsion spring.

[0030] Such as figure 2 and image 3 As shown, the middle plate is provided with a positioning column 13 and a brush box mounting seat, the top of the brush box mounting seat is provided with an opening 14, and the top surface of the brush box is provided with a shrapnel and a boss, and the shrapnel, the boss and the opening are located on the same On the straight line, the brush box is installed in the brush box mounting seat, the carbon brush is located in the brush box, and the tail of the carbon brush is provided with a groove 15 . The edge of the top surface of the brush box extends vertically upwards to form a stopper, which abuts against the brush box insta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap