An automatic pressure supplement and pressure release process system for low-pressure tanks of atmospheric pressure tanks

A process system and low-pressure tank technology, which is applied in the field of automatic pressure supplement and pressure relief process system for low-pressure tanks of atmospheric tanks, can solve the problems of VOCs emissions, difficult VOCs treatment, and pollution, so as to protect the environment, eliminate VOCs emissions, The effect of increasing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the content of the present invention easier to understand, the technical solutions of the present invention will be further described below in conjunction with specific embodiments, but the present invention is not limited thereto.

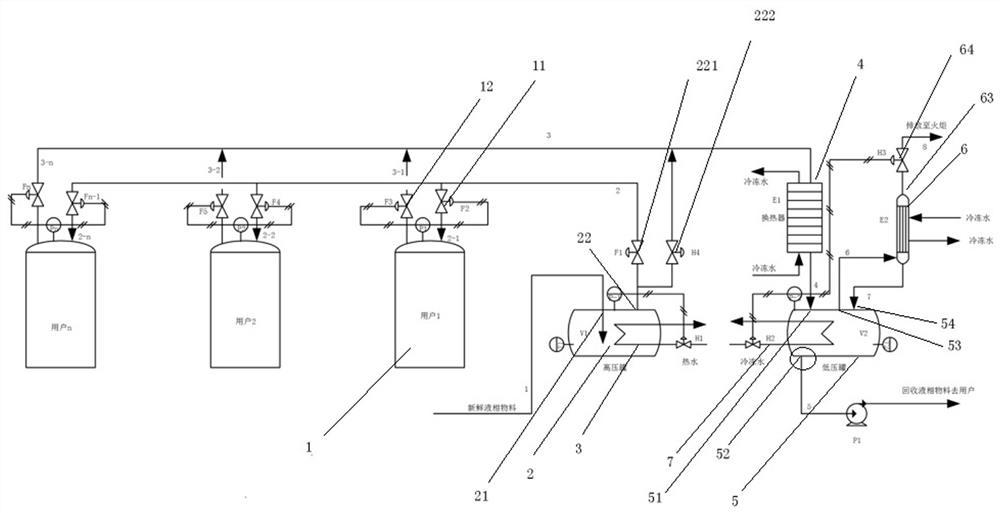

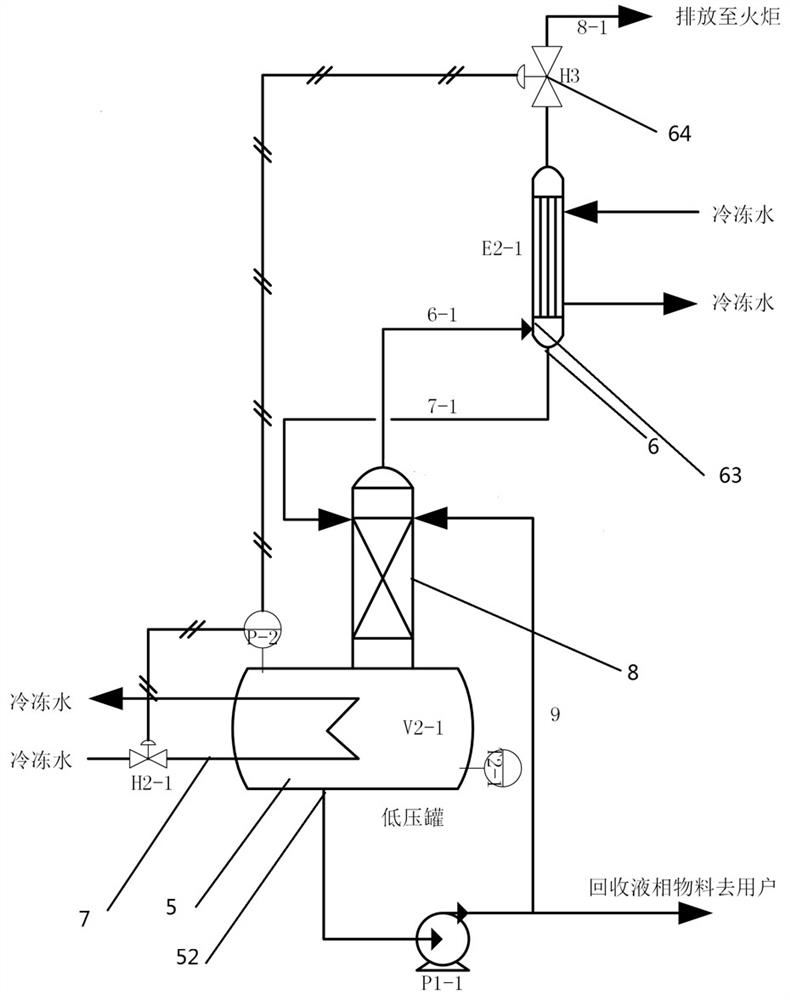

[0023] A kind of atmospheric pressure tank 1 automatic pressure supplement and pressure relief process system, such as figure 1As shown, it includes a user unit, a pressure supplement unit, a pressure relief unit, and a PLC control unit. The user unit includes at least one atmospheric tank 1, and the normal pressure tank 1 is provided with a first pressure supplement valve 11 and a first pressure relief valve. Valve 12, the pressure supplementing unit includes a high-pressure tank 2, a heating device 3 for heating and pressurizing the high-pressure tank 2, and at the same time, the first gas phase material outlet of the high-pressure tank 2 is connected in parallel with a nitrogen line designed in the prior art for Auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com