Abrasion detection method of roll disk type coal mill nozzle ring

A detection method, nozzle ring technology, applied in the direction of testing wear resistance, etc., can solve the problems of large discharge of pebbles, nozzle ring falling off, weakened connection strength, etc., to achieve the effect of ensuring work quality, convenient detection, and avoiding detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0034] In the present invention, the following will refer to the attached Figures 1 to 5 The present invention will be described in detail in combination with embodiments.

[0035] The present invention proposes a wear detection method for a nozzle ring of a roller disc coal mill, including:

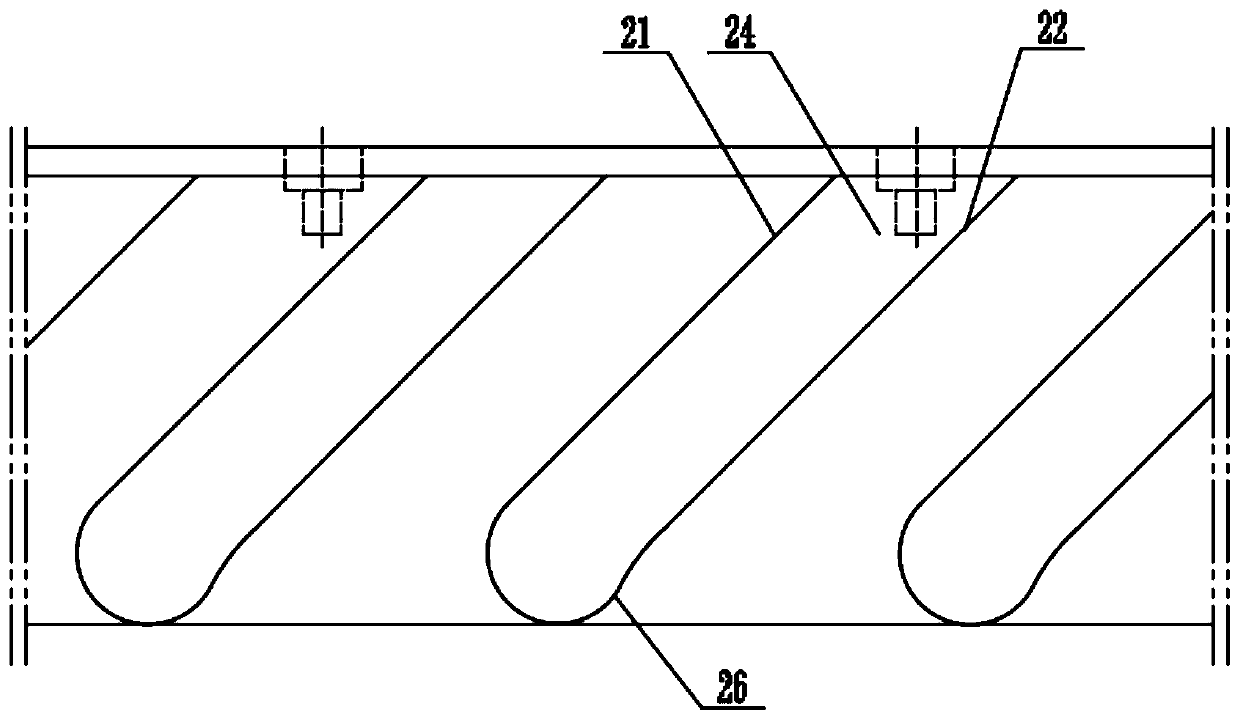

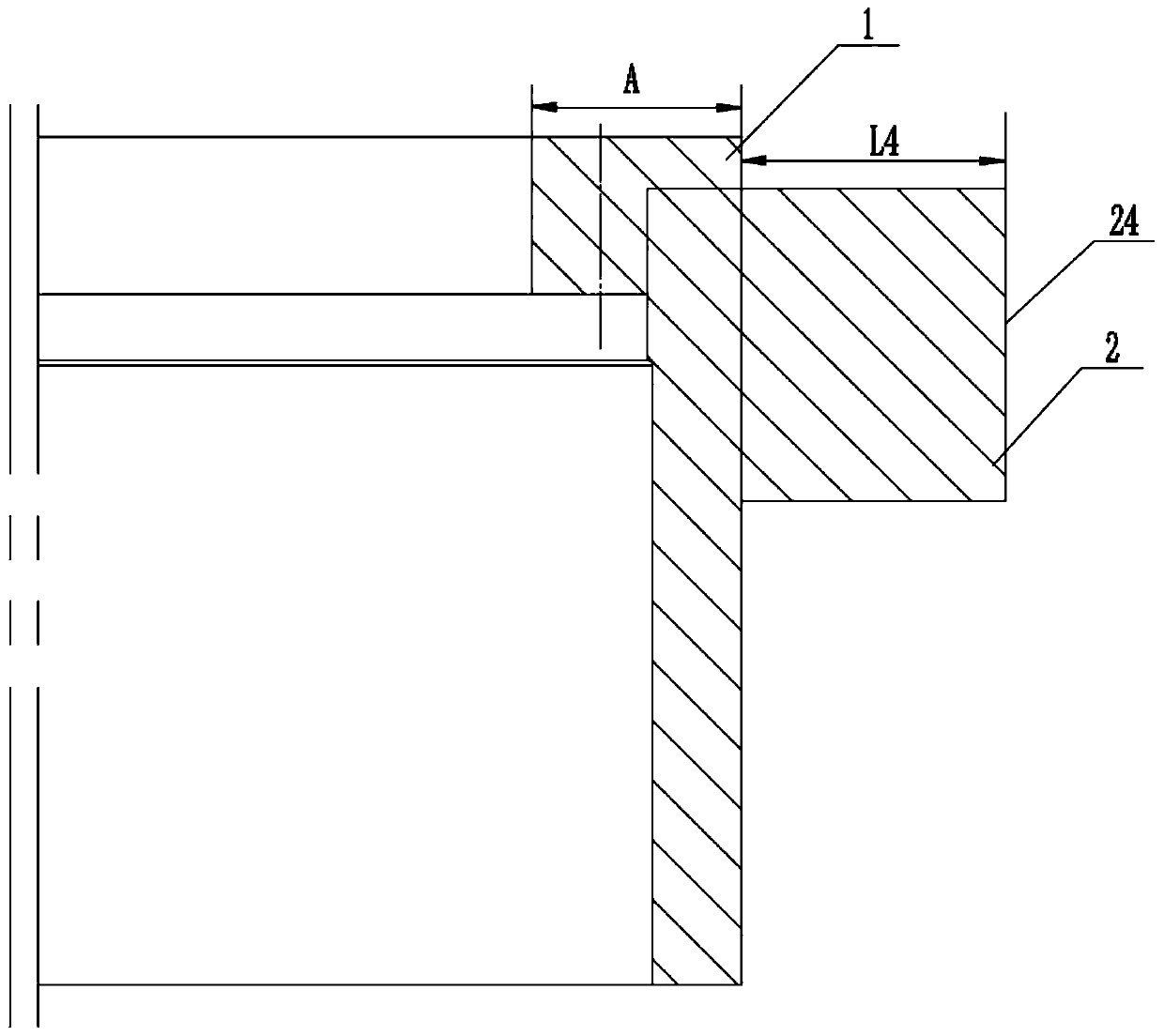

[0036] Selecting the measurement section 4: the measurement section 4 is a plane passing through the central axis of the nozzle ring and intersecting the wear surface 25 of the nozzle vane 2;

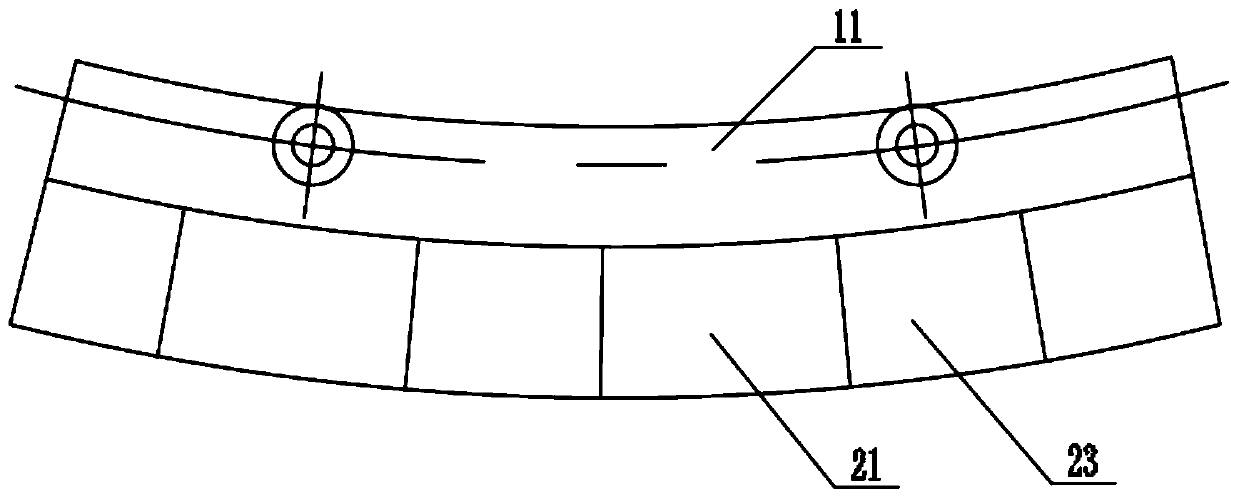

[0037] Detect the amount of wear of the nozzle step 1: the intersection line between the upper surface 11 of the nozzle step and the measurement section 4 is a line segment L1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com