Arc extinguishing and short circuit current resisting direct-current relay

A DC relay and anti-short-circuit technology, which is applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of large difference in positive arc extinguishing effect, being subjected to Lorenz force, and reducing the short-circuit resistance of products, etc., to achieve Improve short-circuit current resistance and facilitate use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

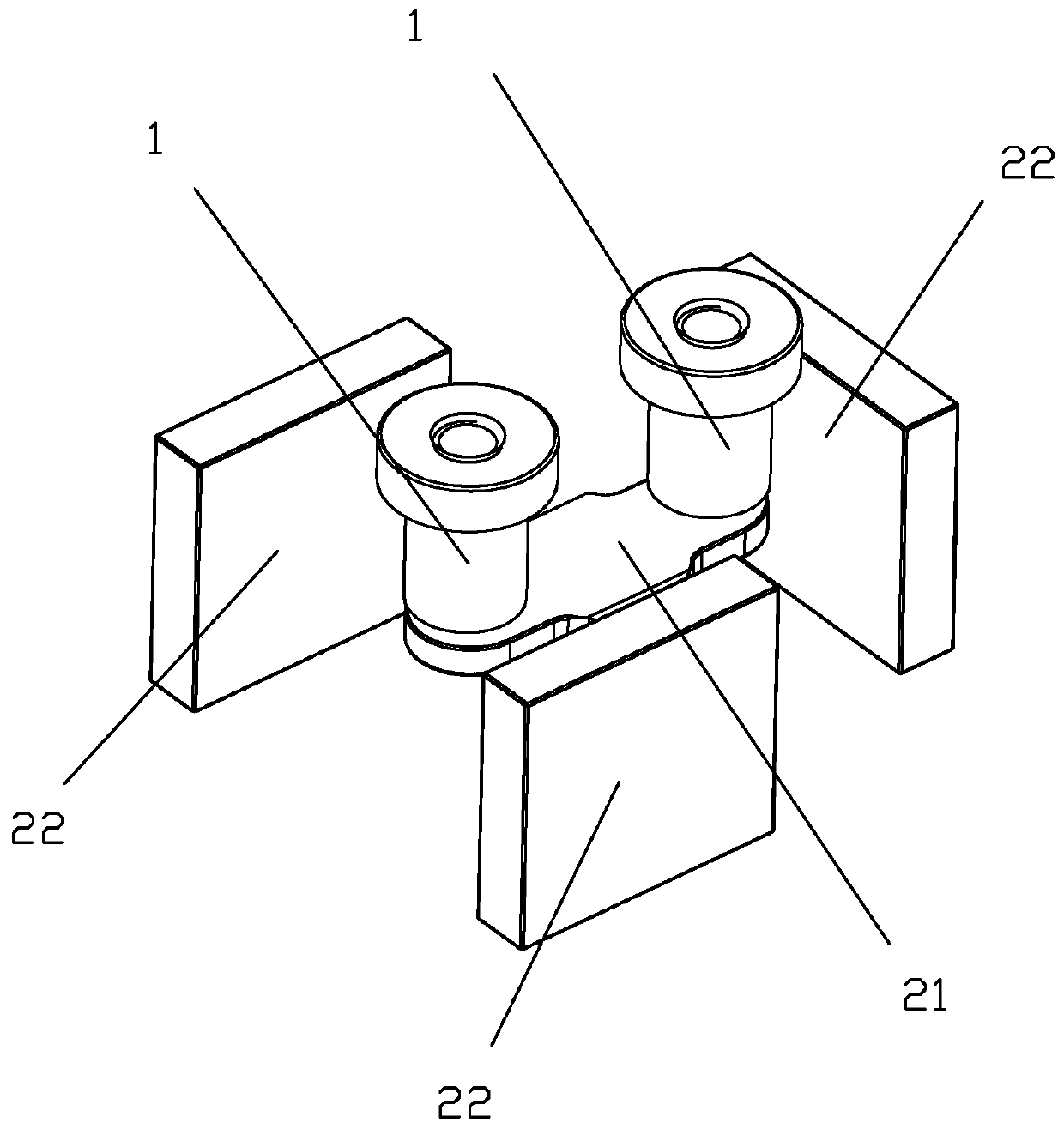

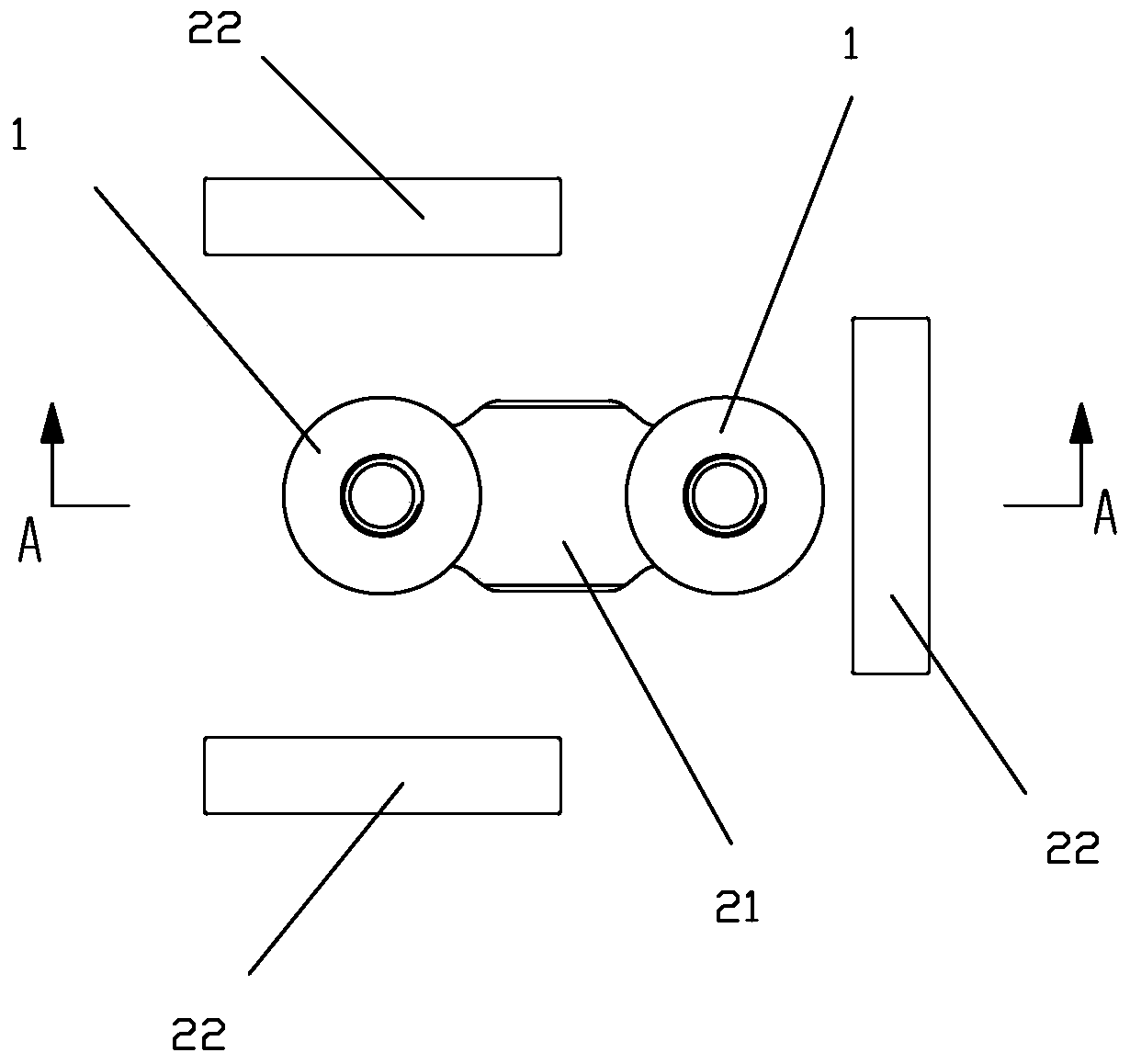

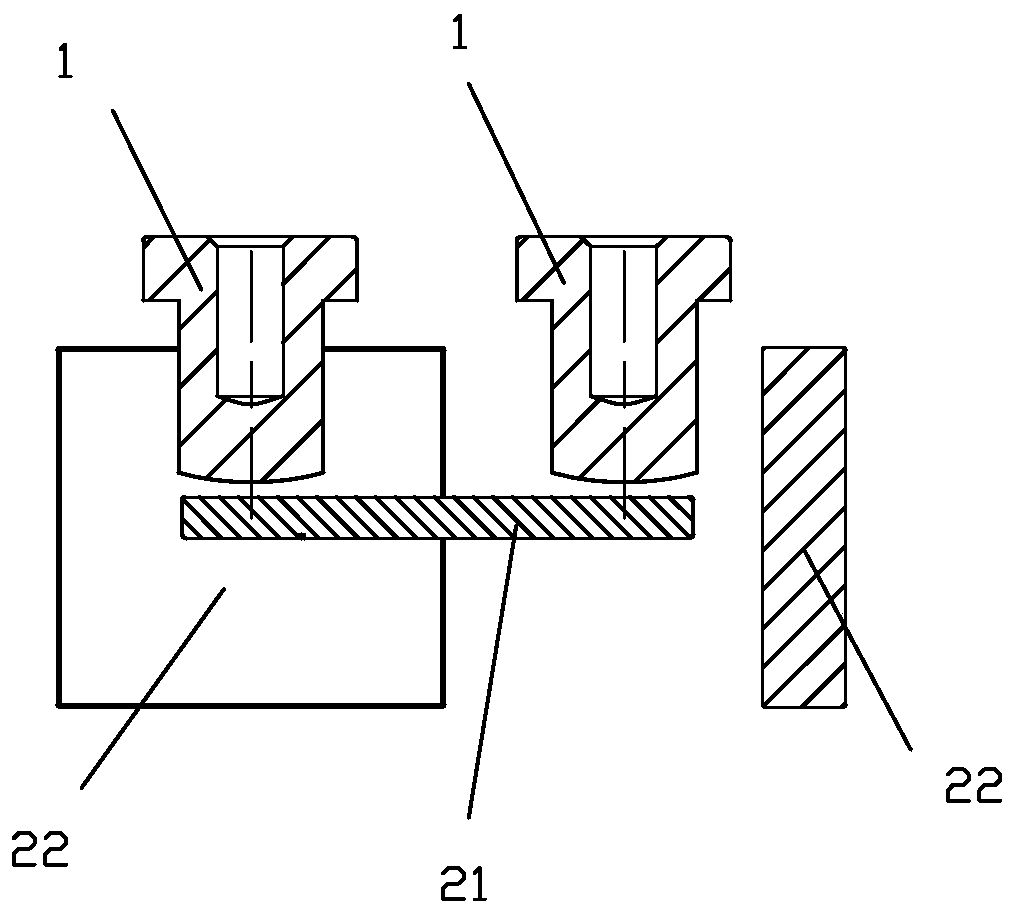

[0062] see Figure 1 to Figure 3 As shown, a kind of arc extinguishing and anti-short-circuit current DC relay of the present invention includes two static contact terminals 1, a straight piece type moving reed 21, a push rod part (not shown in the figure) and Three pieces of magnetic steel 22; the moving reed 21 is installed in the push rod part, so as to realize the moving contact at the two ends of the moving reed 21 and the static contact at the bottom of the two static contact lead-out ends 1 under the action of the pushing rod part Matching; in this embodiment, the two ends of the moving reed 21 constitute the moving contact of the moving reed 21, and the bottom end of the static contact lead-out 1 constitutes the static contact of the static contact lead-out 1; Among the three magnets 22, two magnets 22 are arranged on the outsides of the two sides of the width of the moving reed 21 respectively, and are in a position corresponding to one of the moving and static contac...

Embodiment 2

[0068] see Figure 4 to Figure 8 As shown, the DC relay of a kind of arc extinguishing and anti-short circuit current of the present invention is different from Embodiment 1 in that it also includes two U-shaped yoke clips 23, and the U of one yoke clip 23 (left side) The two sides of the type are respectively connected to the side of the two magnetic steels 22 (left side) facing away from the moving and static contacts, and the U-shaped bottom edge of one of the yoke clips 23 (left side) is in the The outside of the other side (left side) of the length of moving reed 21; The two sides of the U shape of the other yoke clip 23 (on the right) are respectively located outside the two sides of the width of the moving reed 21 and correspond to the other moving and static contacts (on the right).

[0069] In this embodiment, the sides of the three magnets 22 facing the dynamic and static contacts are all set as S poles. The blowing direction of the formed arc extinguishing magneti...

Embodiment 3

[0072] see Figure 9 to Figure 16 As shown in the present invention, a DC relay for arc extinguishing and anti-short circuit current, the push rod part includes a first U-shaped bracket 31 in an inverted shape, a spring 32, a spring seat 33 and a push rod 34, and the push rod 34 is fixed to the spring seat 33, the bottom of the first U-shaped bracket 31 is fixed to the spring seat 33, and the moving reed 21 is installed on the first U-shaped bracket 32 through the spring 32. In the bracket 31; the difference from the second embodiment is that the moving reed 21 is also equipped with an anti-short circuit structure with at least two magnetic conducting rings formed by the combination of the upper yoke and the lower armature. When the reed has a fault and a large current, it can generate suction in the direction of the contact pressure to resist the electrodynamic repulsion between the movable reed and the terminal of the static contact due to the fault current.

[0073] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com