Cooling device for dry-type transformer and using method

A technology for dry-type transformers and cooling devices, which is applied in the direction of transformer/inductor cooling and temperature control using electric methods. It can solve problems such as overload and short-circuit resistance, dry-type transformer burnout, and short insulation life. Improve overload and short-circuit current resistance, ensure safe operation, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

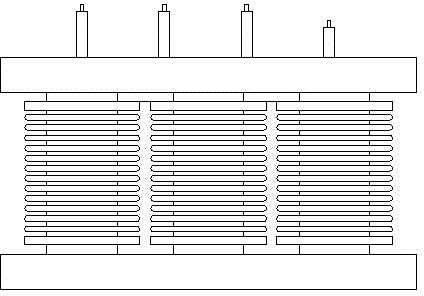

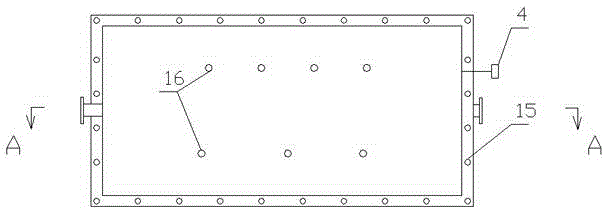

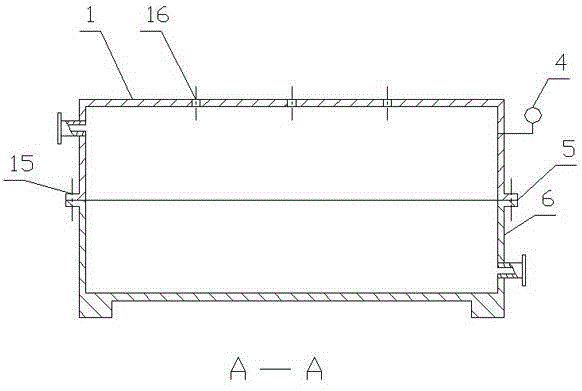

[0023] like Figure 1~8 As shown, a dry-type transformer cooling device includes a cooling chamber, a refrigeration system and a control module. The round hole through which the low-voltage bushing passes, and the part of the bushing passing through the round hole is tightly sealed by the sealing ring. The dry-type transformer is fixed in the cavity of the cooling chamber, and the cooling medium circulates in the cooling chamber. The heat generated by the dry-type transformer is taken away. The refrigeration system performs a refrigeration cycle on the refrigerant medium to meet the requirements of the refrigerant medium for cooling the dry-type transformer. An inlet valve for the refrigerant is installed on the lower side of the cooling chamber. The other pair of cooling chambers The outlet valve for the refrigerant is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com