Double-piece extruding, cutting and pipe inserting machine

A technology of intubation machine and shearing mechanism, which is applied in the direction of battery assembly machine, sustainable manufacturing/processing, electrode carrier/collector, etc. It can solve the problems of low production efficiency and the inability to cut and extrude the double-piece plate grid , to achieve the effects of fast production speed, easy cutting and extrusion, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

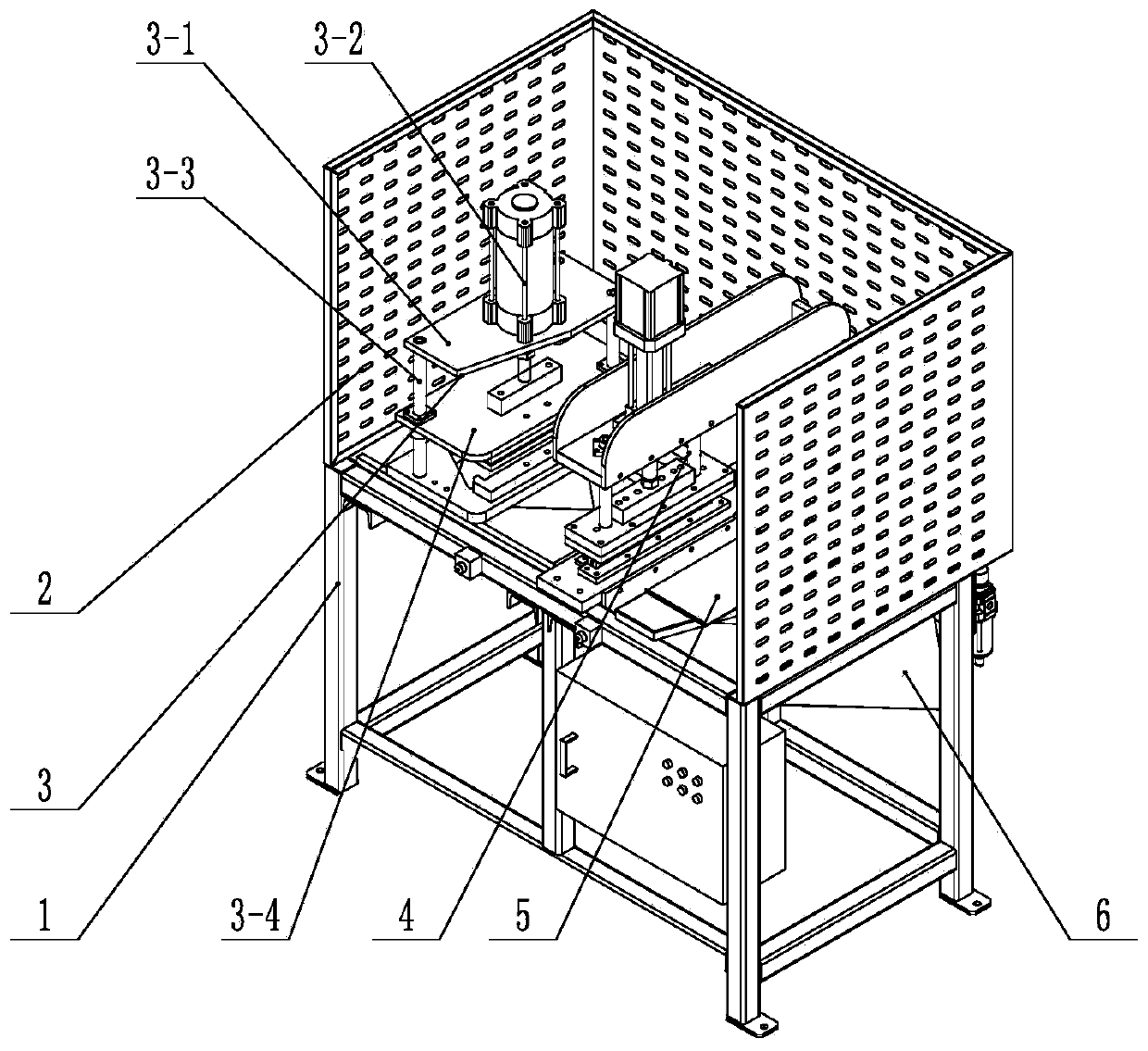

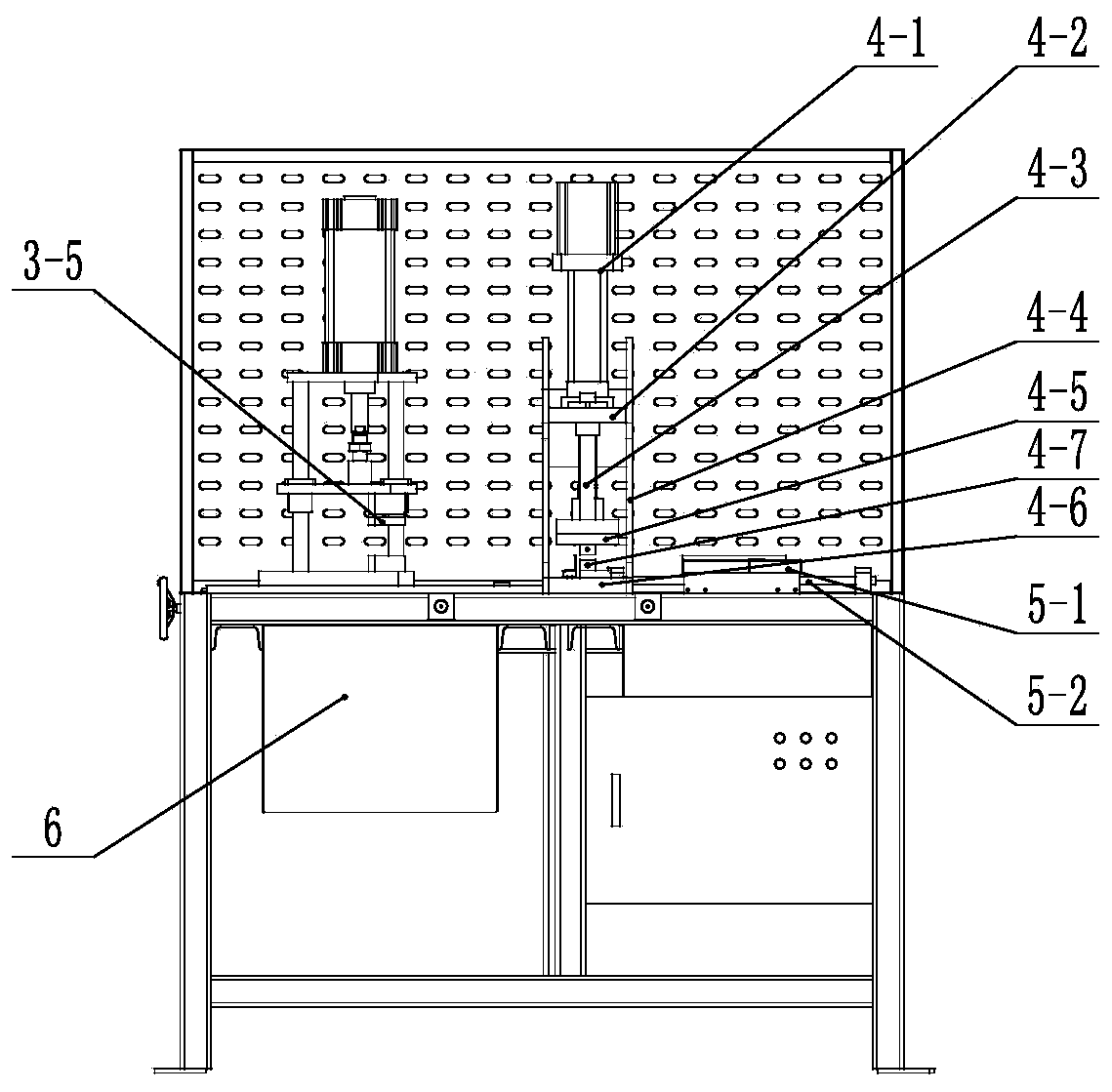

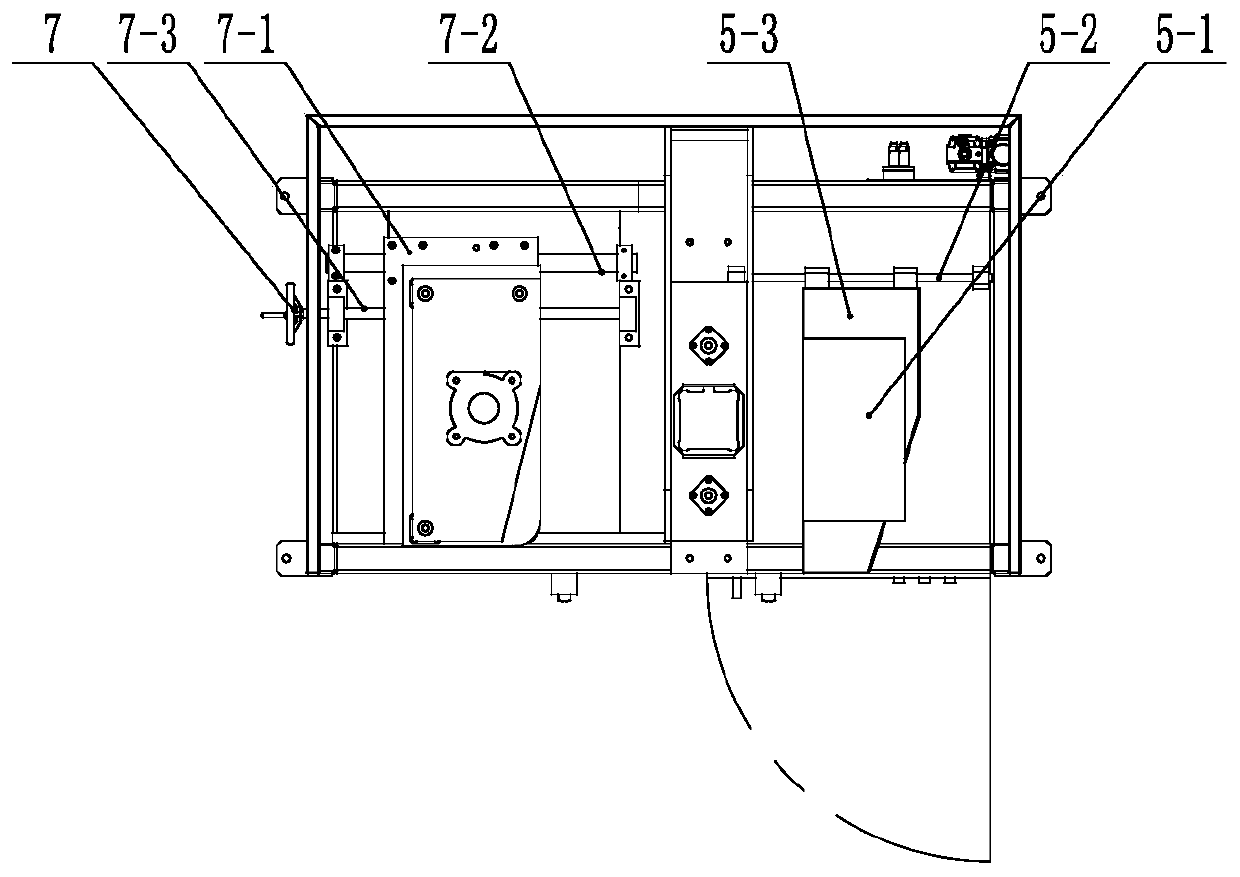

[0030] like figure 1 As shown, a kind of double-sheet extruding and cutting intubation machine of the present invention comprises main frame 1, double-sheet grid 8, and the extruding and cutting assembly 4-7 that double-sheet grid 8 is extruded; also includes:

[0031] A shearing mechanism 3 for shearing the two grid gates 8-1 on the front side of the double-sheet grid 8;

[0032] Extruding and cutting mechanism 4 for extruding and cutting the front extruding tip 8-2 of the grid on the rear side of the double-piece grid 8;

[0033] The bracket carrying mechanism 5 used to transport the trusteeship to the front extrusion tip 8-2 of the grid and complete the intubation operation, the bracket carrying mechanism 5 is arranged at the rear of the extrusion cutting mechanism 4;

[0034] A positioning device for positioning the grid 8;

[0035] A shearing position adjustment mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com