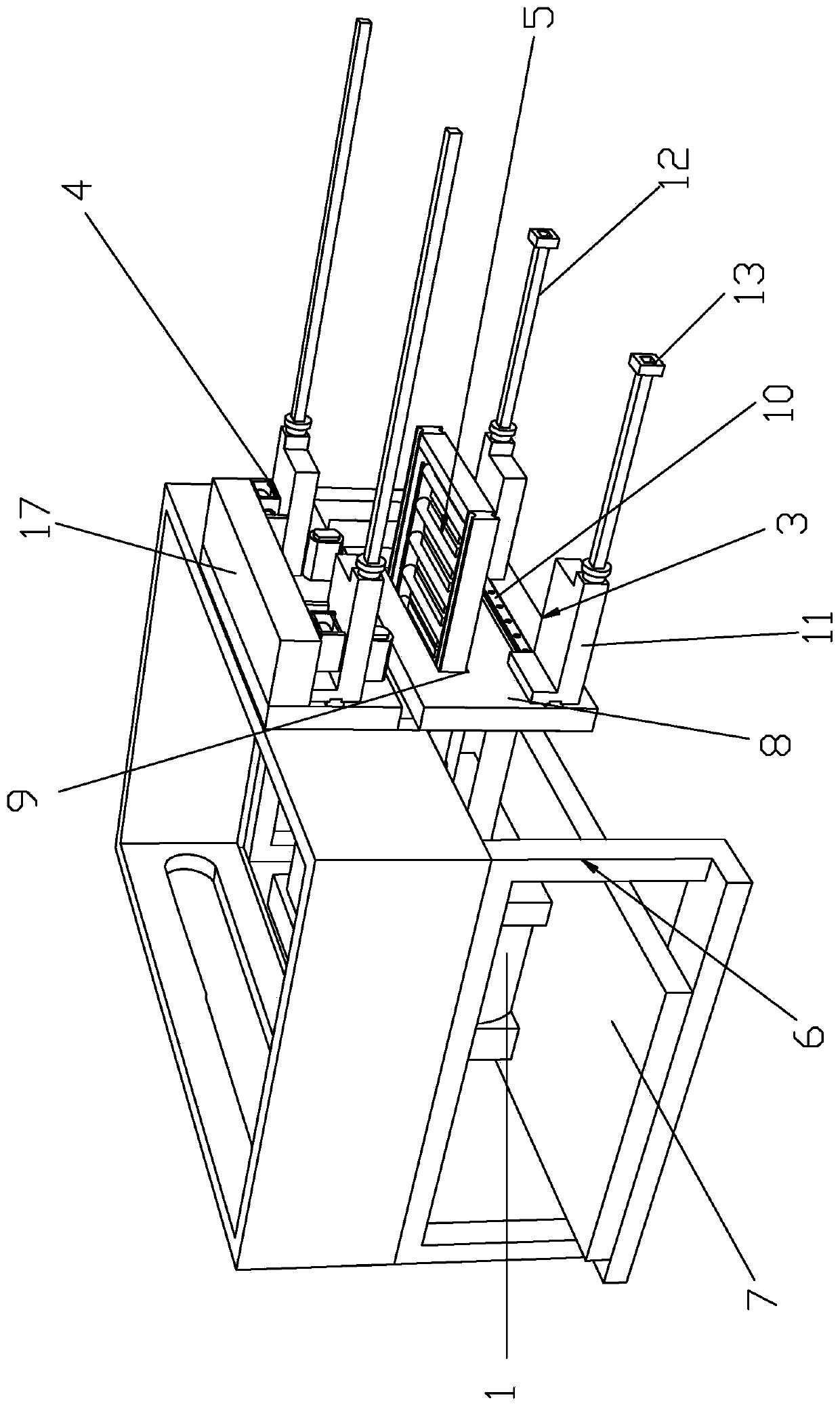

Splitting mechanism for cocoon cage tray disassembling machine

A technology of disc dismantling machine and adjusting mechanism, which is applied in the field of insect breeding, can solve the time-consuming and labor-intensive problems of manpower dismantling, and achieve the effect of reducing cumbersomeness, reducing cumbersome handling, and facilitating industrial sericulture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

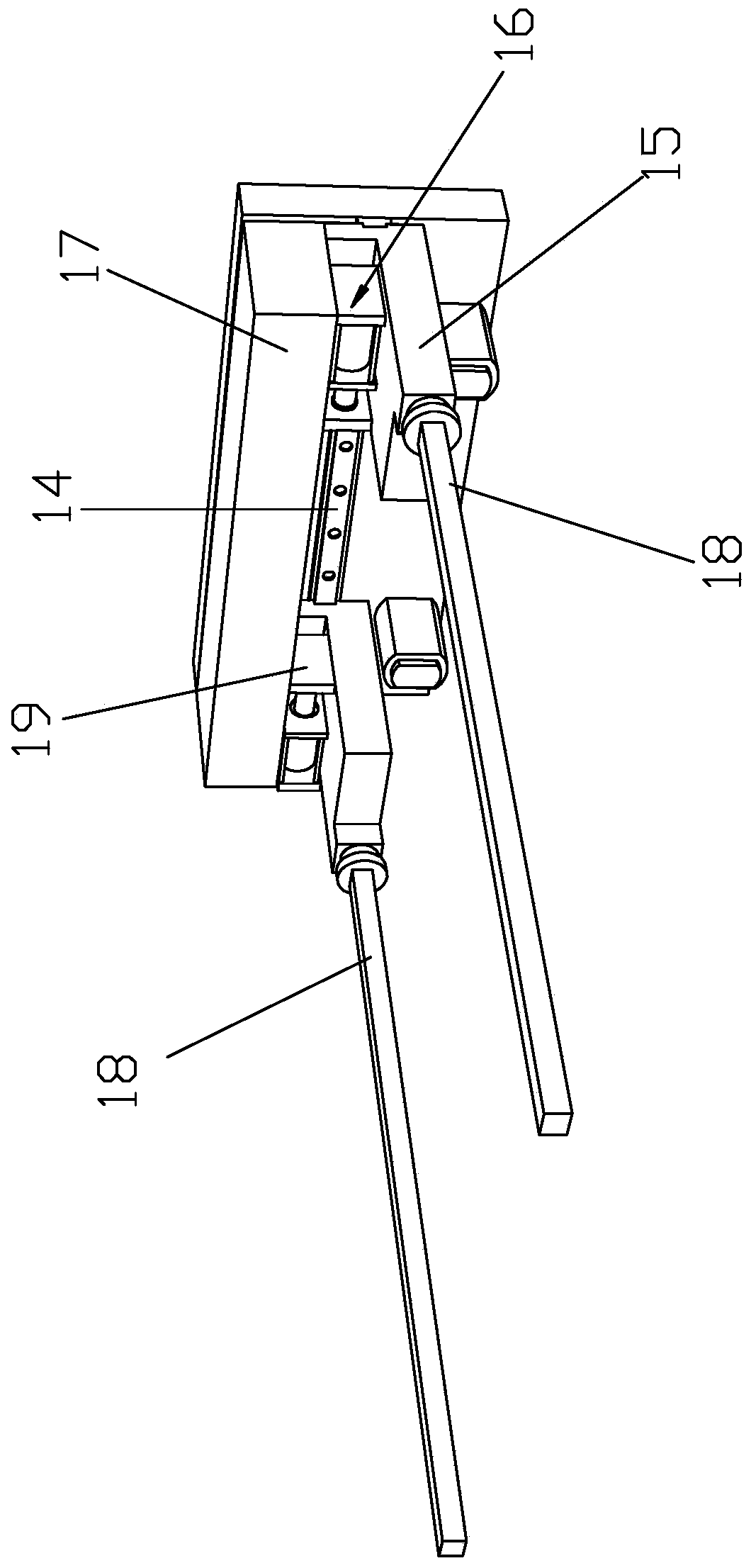

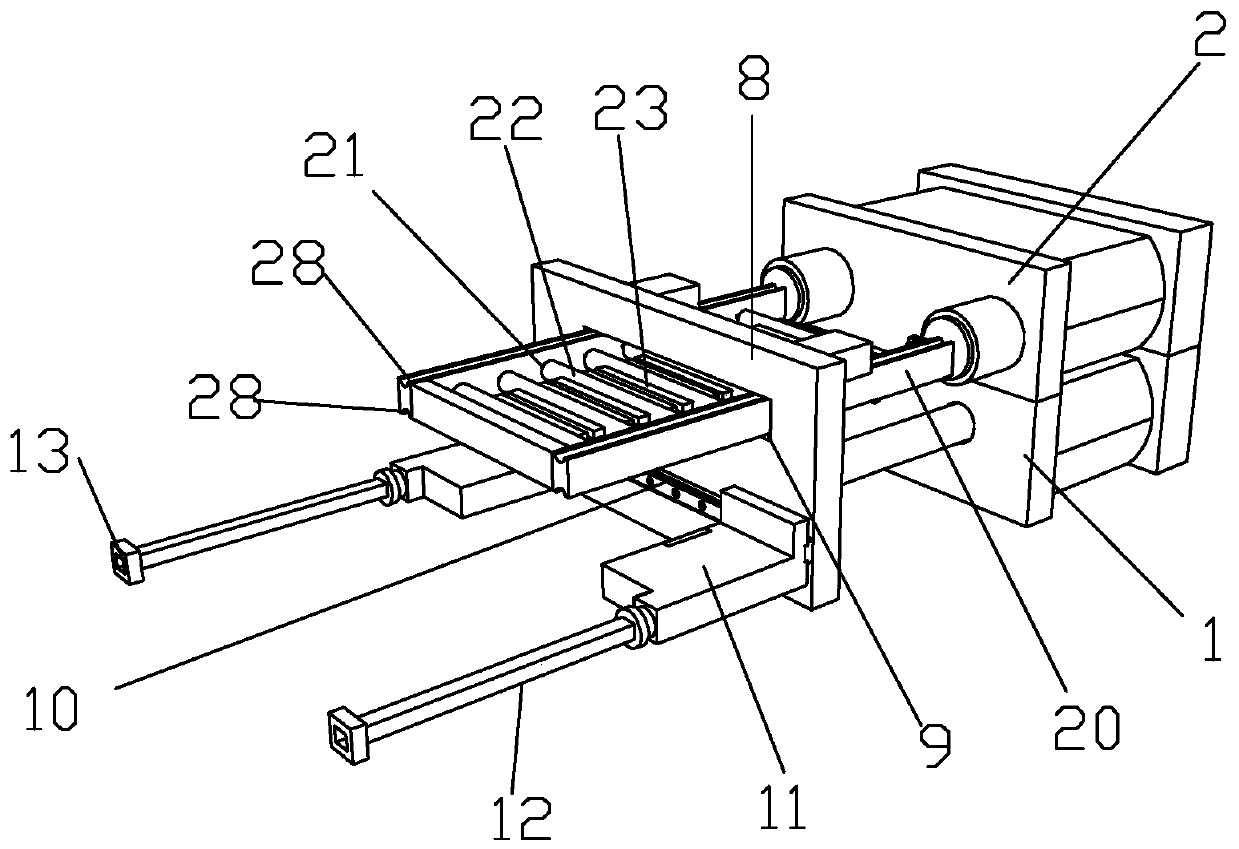

[0035] The specific embodiment: when the breeding frame is transferred to the position of the clamping mechanism 4, the split frame 6 is promoted, so that the clamping strips 18 on both sides of the clamping mechanism are respectively located on both sides of the breeding frame on the upper floor, and the propulsion mechanism 16 is started, so that The clamping bar 18 clamps the upper layer of the breeding frame. After the fixing is completed, the first cylinder 1 is started, and the lower layer of the breeding frame is ejected through the split mechanism 3 to complete the split. During the process of ejection, the second cylinder 2 starts to adjust at the same time. The mechanism 5 slides along the connecting groove 9, so that the adjusting mechanism 5 moves to the bottom of the upper culture plate, starts the third cylinder 27, makes the rotating block 23 rotate, and peels off the silkworm cocoons adhered to the upper culture plate, preventing the bottom of the upper culture p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com