A high-efficiency electrospun fiber biofilm and its preparation method

A technology of electrospun fibers and biofilms, which is applied in the field of water treatment, can solve the problems of increasing the specific surface area of biological fillers, increasing the hydrophilicity of biological fillers, etc., and achieve the effects of improving starting efficiency, strengthening binding, and improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

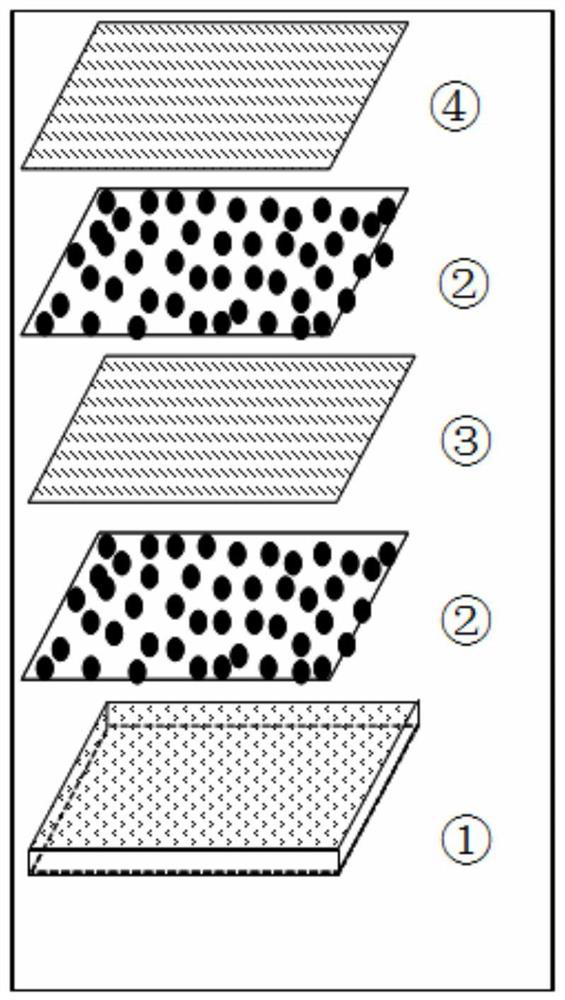

[0035] see figure 1 , the present embodiment provides a high-efficiency electrospun fiber biofilm (substrate+mixed solution+PAN electrospun membrane+mixed solution+PES electrospun membrane), including a substrate, and the substrate is used as a bottom material on which There is a PAN electrospun membrane, and the PAN electrospun membrane is covered with a PES electrospun membrane, wherein the upper surface of the substrate is sprayed with a liquid binder dissolved with composite bacteria; the upper surface of the PAN electrospun membrane is sprayed with A liquid binder in which complex bacteria are dissolved.

[0036] The preparation method of the high-efficiency electrospun fiber biofilm comprises the following steps:

[0037] (1) To prepare a 10% PAN solution, take 200g of PAN powder and 1800g of DMF (N,N-dimethylformamide) solvent. Put in DMF solvent, and use a mechanical stirrer to stir at room temperature for 6 hours at a speed of 600r / min after completion;

[0038] (2...

Embodiment 2

[0046] see figure 1 , the present embodiment provides a high-efficiency electrospun fiber biofilm (substrate+mixed solution+PAN electrospun membrane+mixed solution+PES electrospun membrane), which differs from Example 1 in that the concentration of the prepared PAN solution is 8%, the concentration of the prepared PES solution is 22%, and the mass ratio of liquid binder to composite bacteria is 35:1.

Embodiment 3

[0048] see figure 1 , the present embodiment provides a high-efficiency electrospun fiber biofilm (substrate+mixed solution+PAN electrospun membrane+mixed solution+PES electrospun membrane), which differs from Example 1 in that the concentration of the prepared PAN solution is 12%, the concentration of the prepared PES solution is 26%, and the mass ratio of liquid binder to composite bacteria is 45:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com