Combined filter material biological aerated filter system

A biological aerated filter and aeration system technology, applied in the field of combined filter material biological aerated filter system, can solve the problems of general nitrate nitrogen removal efficiency, insufficient stability of effluent SS, unsatisfactory backwash effect, etc. The effect of comprehensive economic benefits, saving backwashing time and improving backwashing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

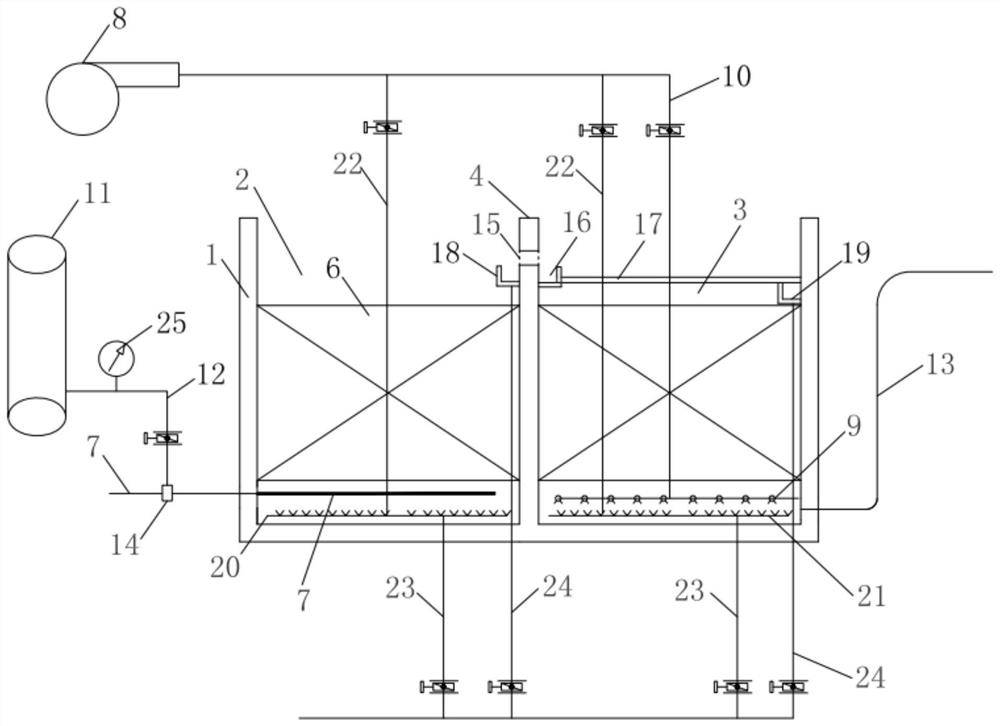

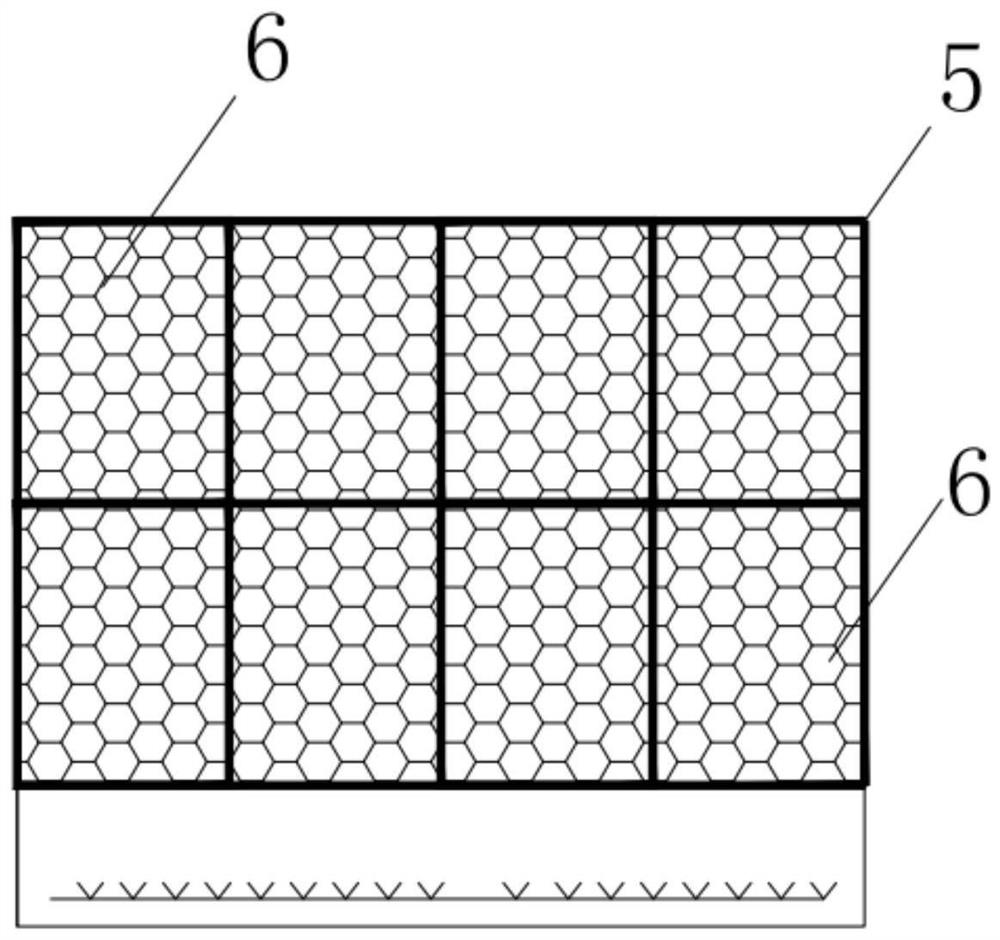

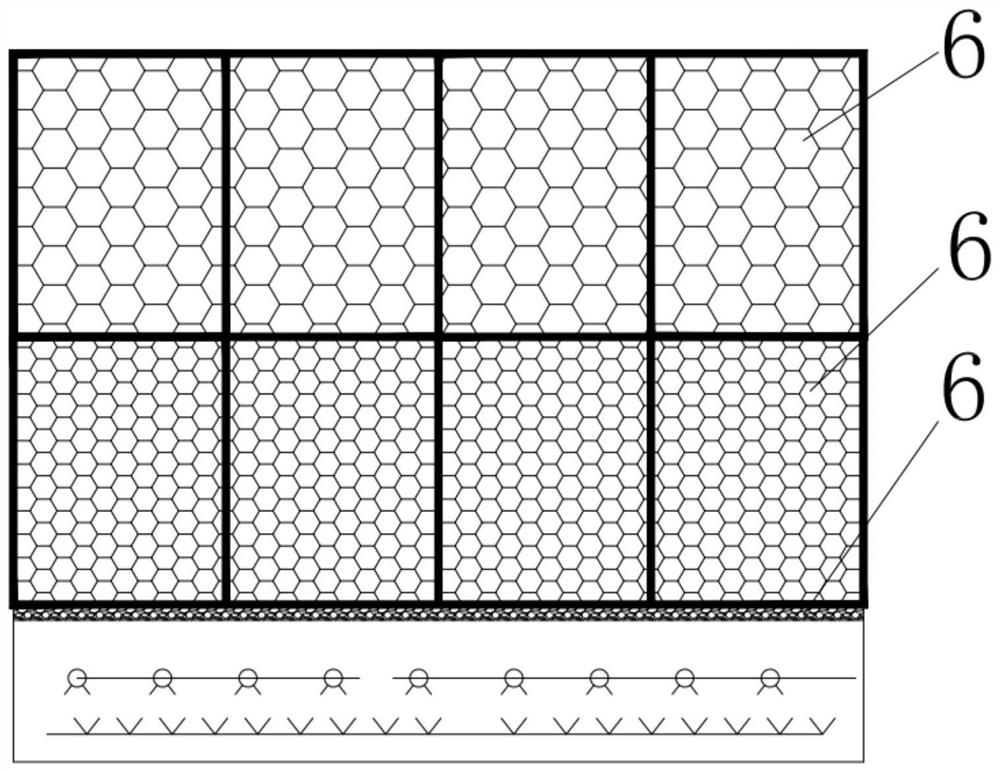

[0046] A combined filter material aerated biological filter system, such as figure 1 As shown, there are two reaction zones in total, which are non-aeration zone 2 and aeration zone 3 respectively, and the height of the filter material layer 6 in aeration zone 3 and non-aeration zone 2 is both 3.5m. The specifications of the filter material: the side length is 3cm, the porosity is above 85%, and the internal pore diameter of the filter material is between 1 and 1.5mm. Wherein the vertical direction is provided with 5 layers of filter material frames 5 in the non-aeration zone 2, the height of the lower two layers of single-layer filter material frames 5 is 1m, and the filling density of the filter material is 85%; the single-layer filter material frames of the upper three layers 5 The height is 0.5m, and the packing density of the filter material is 100%.

[0047] In the aeration area 3, there are three layers of filter material frames 5 in the vertical direction. The height ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com