Purification system and method for electronic-grade carbon tetrafluoride

A carbon tetrafluoride, purification method technology, applied in chemical instruments and methods, halogenated hydrocarbon disproportionation separation/purification, organic chemistry, etc. Use and other problems to achieve the effect of high product purity, less impurities, and lower maintenance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

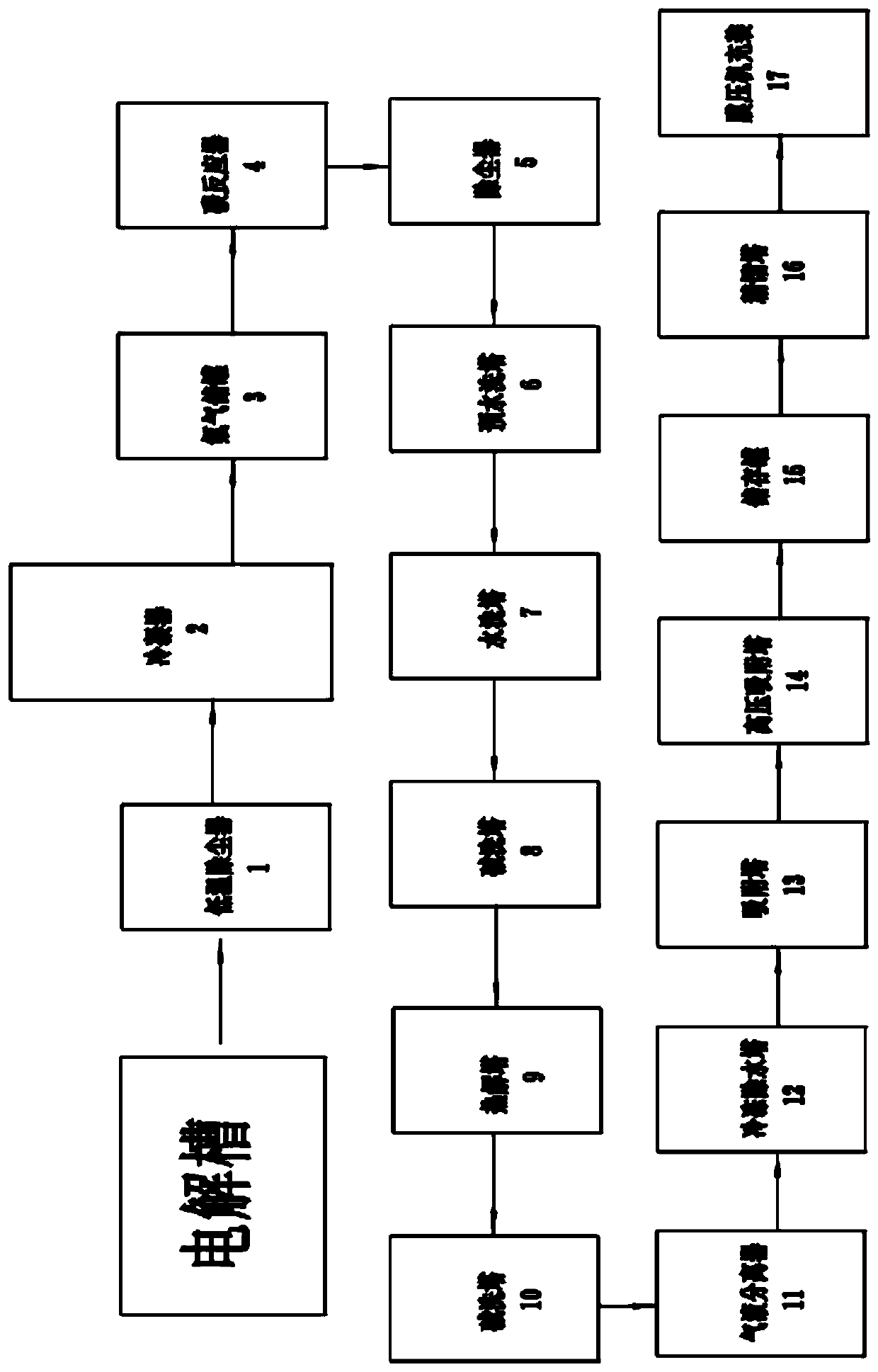

[0073] The preparation system of electronic grade carbon tetrafluoride provided by the present invention includes a fluorine gas source, a reaction device and a purification system. The fluorine gas source is sealed and connected to the reaction device, and the reaction device is sealed and connected to the purification system.

[0074] The fluorine gas source includes an electrolytic cell, a cryogenic dust collector 1 , a condenser 2 and a fluorine gas buffer tank 3 .

[0075] Among them, the electrolytic cell has an automatic system, and the feeding method is liquid level interlocking automatic feeding.

[0076] Wherein, the bottom end of the condenser is provided with a hydrogen fluoride discharging device.

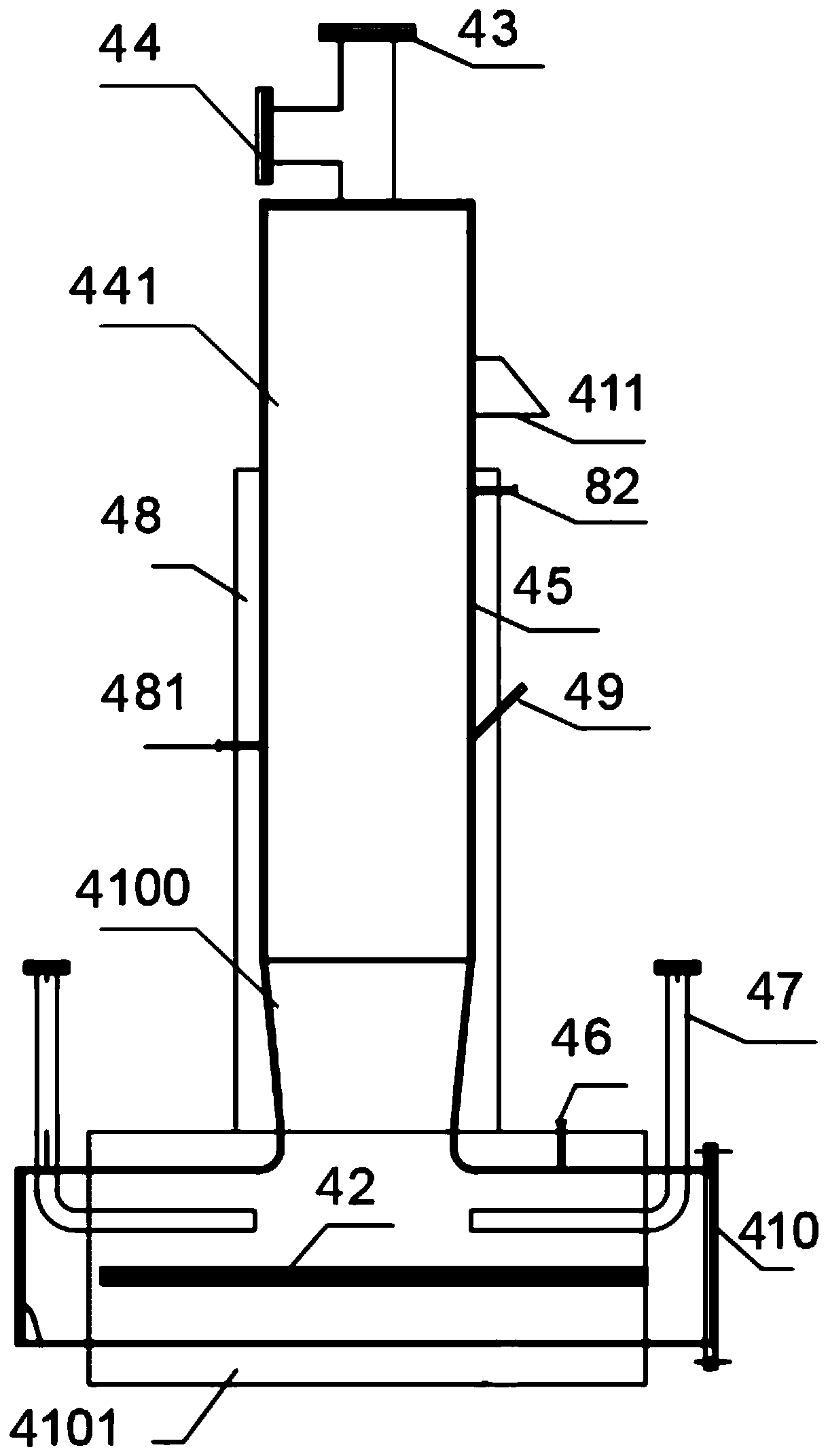

[0077] The reaction device includes a carbon reactor 4 and a dust removal device 5, wherein the carbon reactor also includes a secondary reactor.

[0078] The purification system includes a washing system, an adsorption system and a rectification system. The washing ...

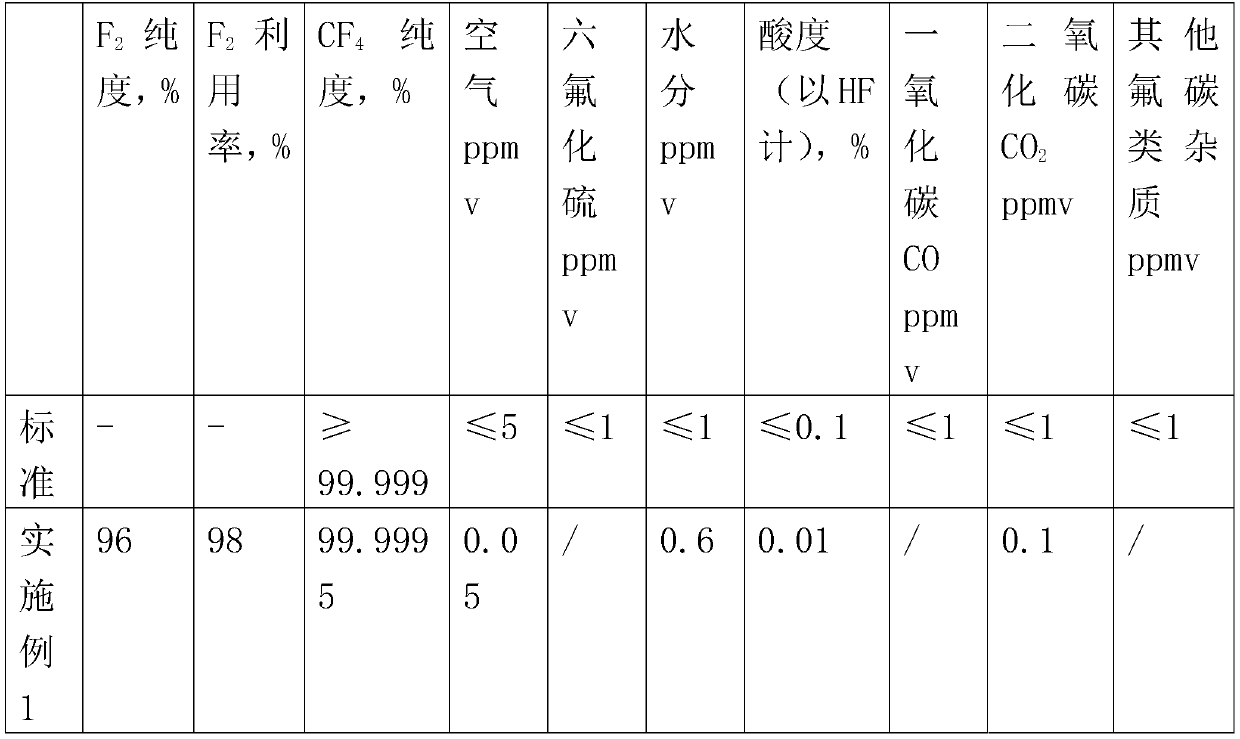

Embodiment 1

[0080] S1. Preparation of fluorine gas: the electrolytic cell automatically produces fluorine gas. After passing through the low-temperature dust collector and condenser, it reaches the fluorine buffer tank;

[0081] Among them, the temperature of the electrolytic cell is controlled at 80-95°C, the acidity is controlled at 40-42%, and the liquid level is interlocked to automatically add hydrogen fluoride and evenly feed, which greatly reduces the excessive addition of hydrogen fluoride. The gas passes through the cryogenic dust collector 1, and the temperature of the dust collector is controlled at 4°C. After the dust and electrolyte in the gas are removed, it enters the condenser 2, and the temperature of the condenser is controlled at -60°C. There is a hydrogen fluoride discharge device at the bottom, which can realize automatic Unloading, recovering hydrogen fluoride for reuse, greatly reduces the cost, and can increase the purity of fluorine gas to more than 95%. The outl...

Embodiment 2

[0101] S1. Preparation of fluorine gas: the electrolytic cell automatically produces fluorine gas. After passing through the low-temperature dust collector and condenser, it reaches the fluorine buffer tank;

[0102] Among them, the temperature of the electrolytic cell is controlled at 95-100°C, the acidity is controlled at 42%, the liquid level is interlocked to automatically add hydrogen fluoride, and the material is evenly added, which greatly reduces the excessive addition of hydrogen fluoride. The gas passes through the cryogenic dust collector 1, and the temperature of the dust collector is controlled at 3°C. After the dust and electrolyte in the gas are removed, it enters the condenser 2, and the temperature of the condenser is controlled at -80°C. There is a hydrogen fluoride discharge device at the bottom, which can realize automatic Unloading, recovering hydrogen fluoride for reuse, greatly reduces the cost, and can increase the purity of fluorine gas to more than 95...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap