Spraying and dust settling device for coal mine heading machine

A technology of spray dust reduction and roadheader, which is applied in the direction of slitting machinery, earth drilling and mining, etc., can solve the problems of complex structure and difficulty in ensuring the stable operation of spray dust reduction, and achieve good dust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

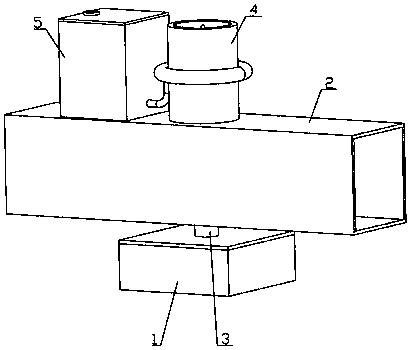

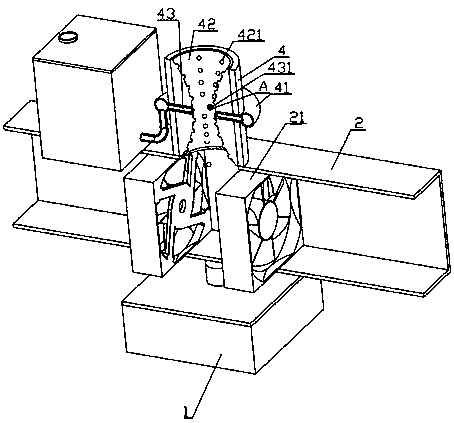

[0033] refer to figure 1 , is a spray dust suppression device for a coal mine roadheader disclosed by the present invention, including a machine case 1, a spray tube 2, a swing device 3 and an air inlet pipe 4. The chassis 1 is a rectangular box structure with a hollow interior, and the chassis 1 is fixedly installed on the roadheader. The opening of the spray tube 2 is square, and its length direction is horizontal, and the spray tube 2 is arranged on the upper side of the cabinet 1 .

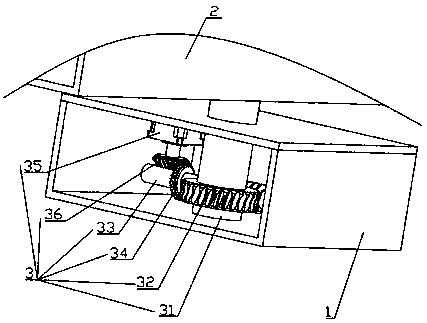

[0034] refer to figure 2, the swing device 3 includes a rotating column 31 , a worm wheel 32 , a worm 33 , a first bevel gear 34 , a servo motor 35 and a second bevel gear 36 . The rotating column 31 is a circular column with a vertical axis. The rotating column 31 is arranged in the cabinet 1. The lower end of the rotating column 31 is rotatably connected with the inner ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap