Symmetric horseshoe-shaped assembled concrete tunnel

A horseshoe-shaped, prefabricated technology, applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve problems such as difficult connection, difficulty in realizing industrialization of prefabricated comprehensive pipe corridors, high construction costs of comprehensive pipe corridors, etc., reaching the scope of application wide, easy to transport and on-site assembly, simple and effective connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they should not be construed as limiting the protection scope of the present invention.

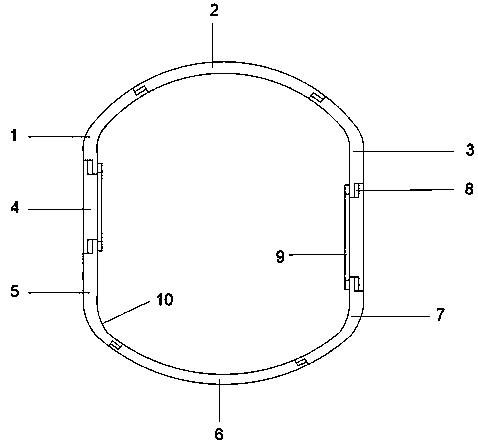

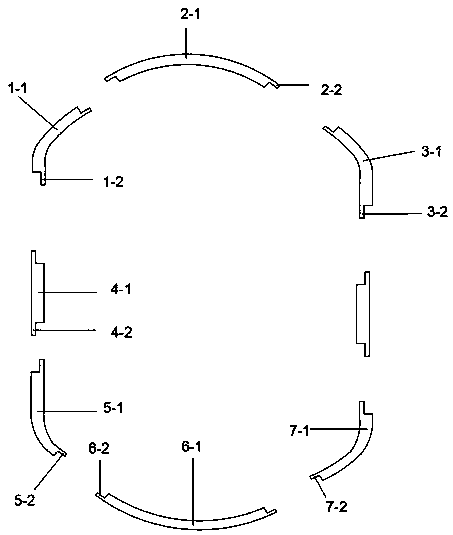

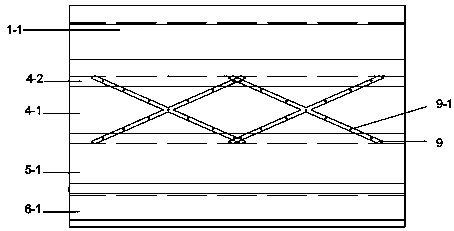

[0030] Such as figure 1 , 2 As shown in , 6, a symmetrical horseshoe-shaped fabricated concrete tunnel of the present invention mainly includes top arched shell plate corner point A1, top arched shell plate 2, top arched shell plate corner point B3, vertical shell plate A4, bottom Arched shell panel corner A5, bottom arched shell panel 6, bottom arched shell panel corner B7 and grouting layer 8, the top arched shell panel corner A1 includes top arched shell panel corner A web 1 -1 and the flange 1-2 of the corner point A of the top arched shell plate; the structure of the corner point B3 of the top arched shell plate and the structure of the corner point A1 of the top arched shell plate are left and right m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com