Self moving type hydraulic forepole

A front-exploring beam and self-moving technology, which is applied to mining equipment, earthwork drilling, mine roof support, etc., can solve the problems of not being able to meet the requirements of on-site safety production, consume a lot of physical strength of the workers, and unfavorable safety hazards, etc., and achieve improvement The utilization rate of working hours, the reduction of labor intensity, and the effect of many safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

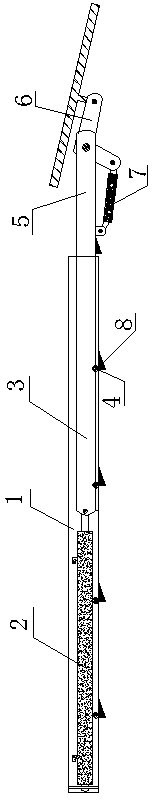

[0014] Self-moving hydraulic front probe beam, including body protection box 1, compensation oil cylinder 2, π-shaped steel 3, bearing 4, hanger 5, is characterized in that: the compensation oil cylinder 2 is fixedly connected with π-shaped steel 3, and fixed on the protection Inside the body box 1, the hanger 5 is composed of a connecting rod 6 and a swing angle cylinder 7, at least two connecting rods 6 are arranged, and the swing angle oil cylinder 7 is fixedly connected with the end of the connecting rod 6, and the hanger 5 and connecting rod 6 are connected by pins, and four blocking teeth 8 are arranged at the bottom of the body protection box 1, and the blocking teeth 8 are fixed on the body protection box 1 through bearings.

[0015] The connecting rods 6 of the present invention form an angle not less than 20 degrees with each other.

[0016] The working process of the present invention is: the present invention controls the elevating and advancing of hanger and stabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com