marine diesel engine

A diesel engine and engine technology, applied in the direction of combustion engines, engine components, machines/engines, etc., can solve the problems of large piping structure, complex opening and closing control of switching valves, and complexity, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

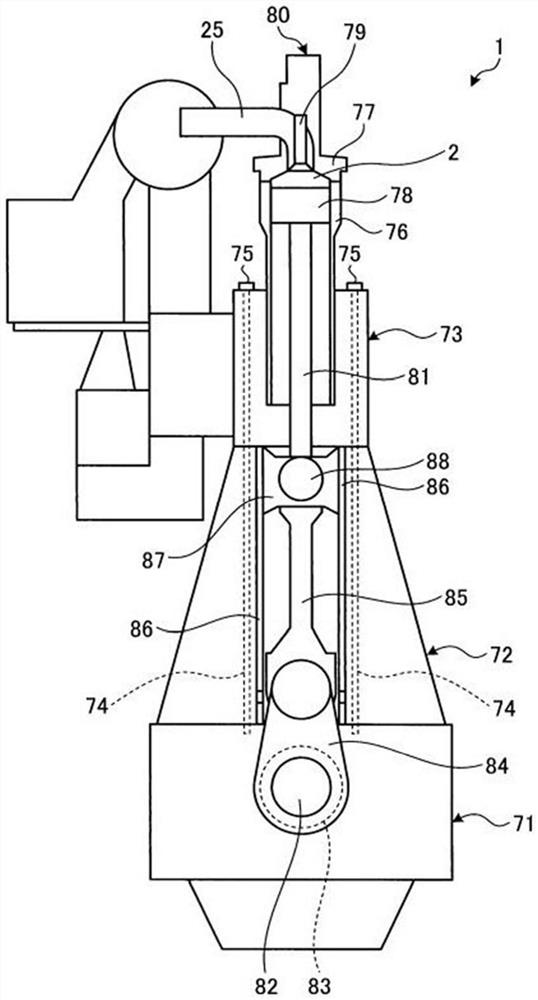

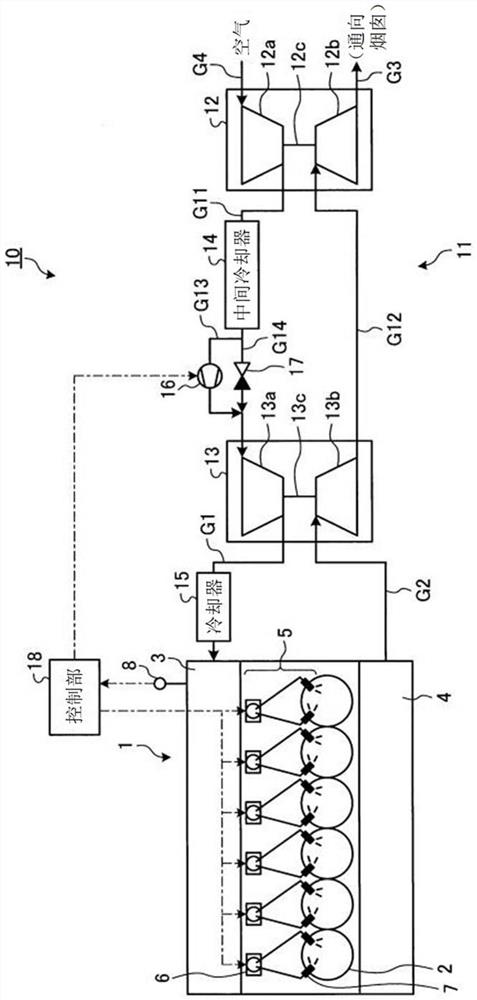

[0019] Hereinafter, preferred embodiments of the marine diesel engine of the present invention will be described with reference to the drawings. In addition, this invention is not limited based on this embodiment. In addition, the drawings are schematic, and it should be noted that the dimensional relationship of each element, the ratio of each element, and the like may differ from actual ones. Between the drawings, there may be cases where parts with different dimensional relationships and ratios are included. In addition, in each drawing, the same code|symbol is attached|subjected to the part of the same structure.

[0020] (Structure of Marine Diesel Engine)

[0021] Hereinafter, first, the schematic structure of the engine main body of the marine diesel engine according to the embodiment of the present invention will be described, and then the overall structure of the marine diesel engine will be described.

[0022] figure 1 It is a schematic diagram showing an engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com