A kind of preparation method of nylon powder for selective laser sintering

A technology of laser sintering and nylon powder, which is applied in the field of preparation of nylon powder for selective laser sintering, which can solve the problems of warpage and deformation of sintered parts, poor dispersion of powder materials, and uneven particle size distribution, etc., to increase the crystallization density , compact structure, and easy-to-implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

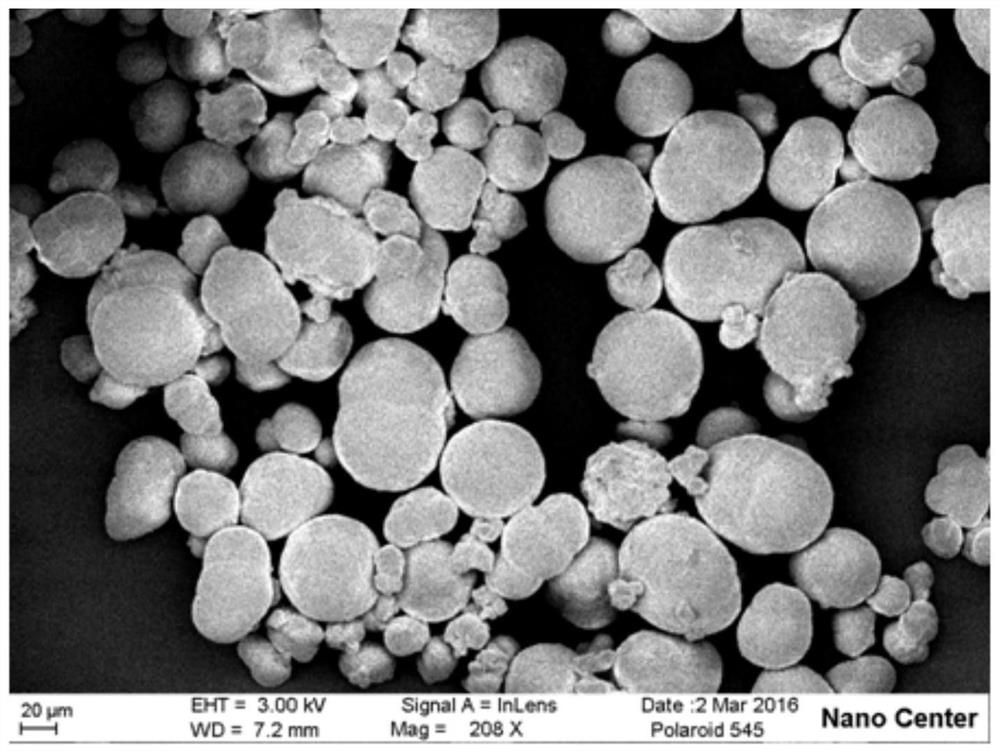

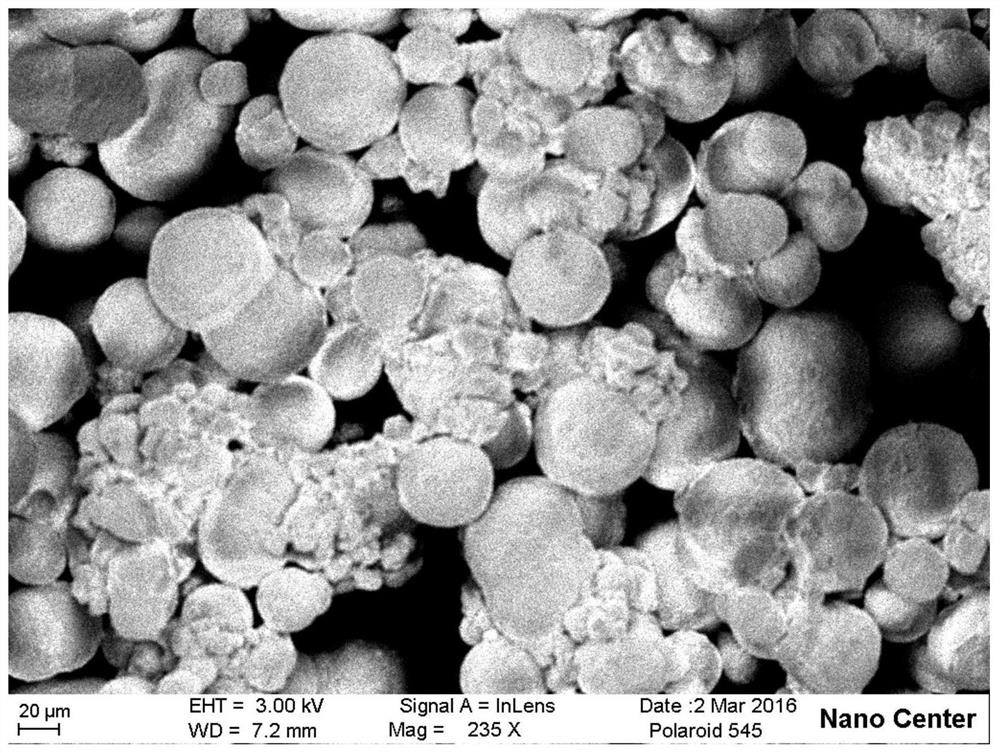

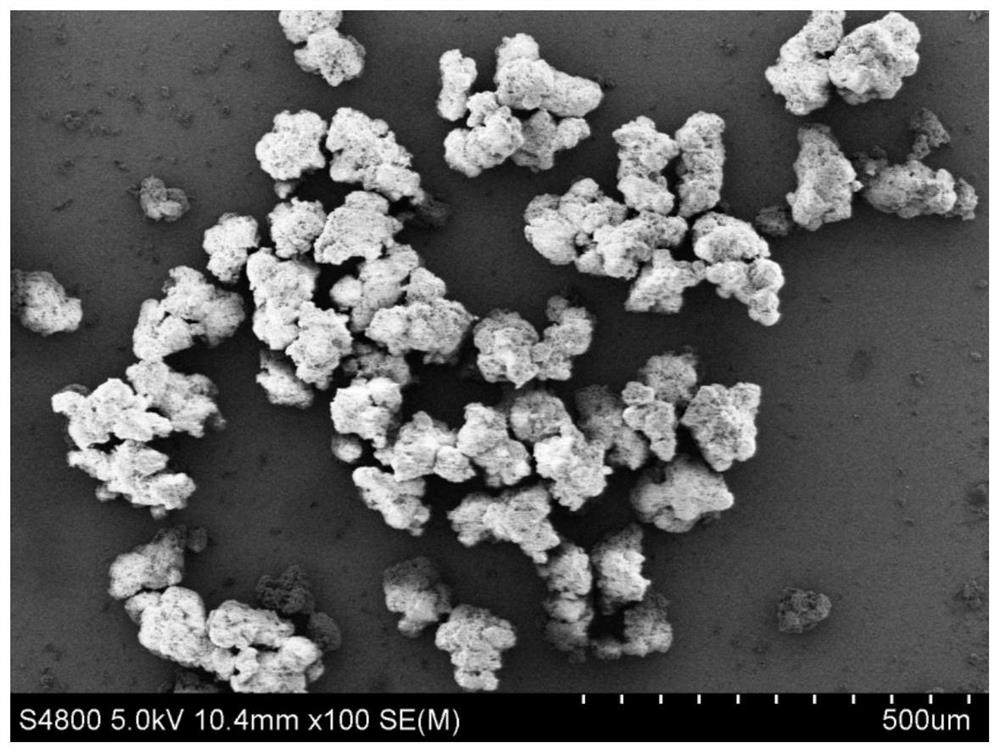

[0039]100g nylon 6 pellets, 1g polyvinyl alcohol (PVA), 1g lithium benzoate, and 1000ml formic acid were added to the reaction kettle, and stirred at 1200r / min stirring speed for 2h at room temperature to completely dissolve the materials to form a homogeneous transparent solution. Add deionized water uniformly under the condition of 120 drops / min until the system becomes milky white. The temperature of the system is increased to 80°C, and the system becomes a homogeneous transparent solution again, and then the reaction kettle is placed in a constant temperature water bath at 5°C to cool rapidly, and the powder is precipitated After filtering and washing several times until the pH of the supernatant is 7, then drying and passing through a 200-mesh sieve to obtain nylon 6 powder for selective sintering.

Embodiment 2

[0041]100g nylon 6 pellets, 0.5g polyvinyl alcohol (PVA), 0.5g lithium benzoate, and 800ml formic acid were added to the reaction kettle, and stirred for 2h at a stirring speed of 1000r / min at room temperature to completely dissolve the materials and form a homogeneous transparent solution. Then uniformly add deionized water under the condition of 80 drops / min until the system becomes milky white. The temperature of the system is increased to 120°C, the system becomes a homogeneous transparent solution again, and then the reaction kettle is placed in a constant temperature water bath at 0°C to cool quickly. The powder is separated out, filtered and washed several times until the pH of the supernatant is 7 and then dried and passed through a 200-mesh sieve to obtain nylon 6 powder for selective sintering.

Embodiment 3

[0043]100g nylon 12 pellets, 1g Span 80, 1g lithium benzoate, 1000ml trifluoroacetic acid were added to the reaction kettle, and stirred at 1200r / min stirring speed for 2h at room temperature to completely dissolve the materials to form a homogeneous transparent solution. Add deionized water uniformly under the condition of drops / min until the system becomes milky white. The temperature of the system is increased to 70°C, and the system becomes a homogeneous transparent solution again. Then the reaction kettle is placed in a constant temperature water bath at 5°C to cool rapidly, and the powder is precipitated. After filtering and washing several times until the pH of the supernatant is 7, it is dried and passed through a 200-mesh sieve to obtain nylon 6 powder for selective sintering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com