Automatic juvenile shellfish dispensing device

A shellfish and blanking device technology, applied in the field of fishery machinery, can solve the problems of increasing shellfish fatality rate, long operation time, poor operation safety, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

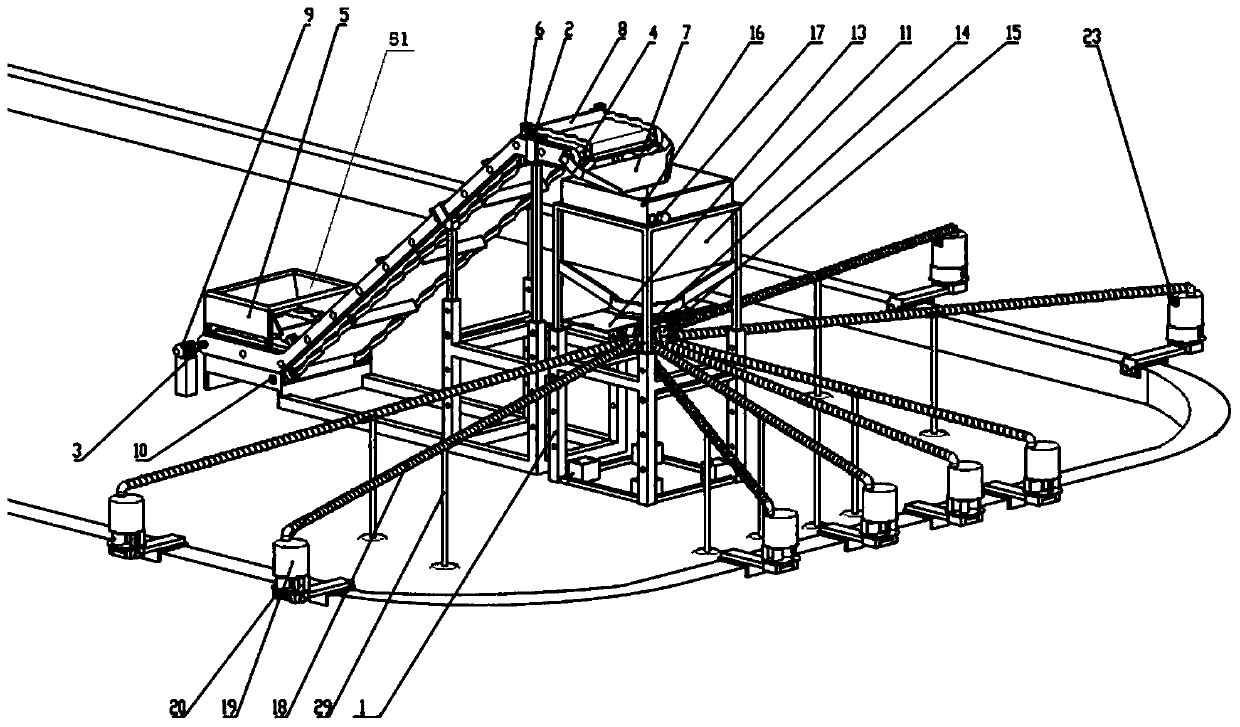

[0078] A shellfish sowing device, such as Figure 1-10 As shown, including feeding device and spreading device;

[0079] Described blanking device comprises hopper 11 and seedling divider 14, and seedling divider 14 is located at hopper 11 discharge opening, has a plurality of discharge openings, and sowing device comprises at least the discharge channel 18 corresponding to each discharge opening .

Embodiment 2

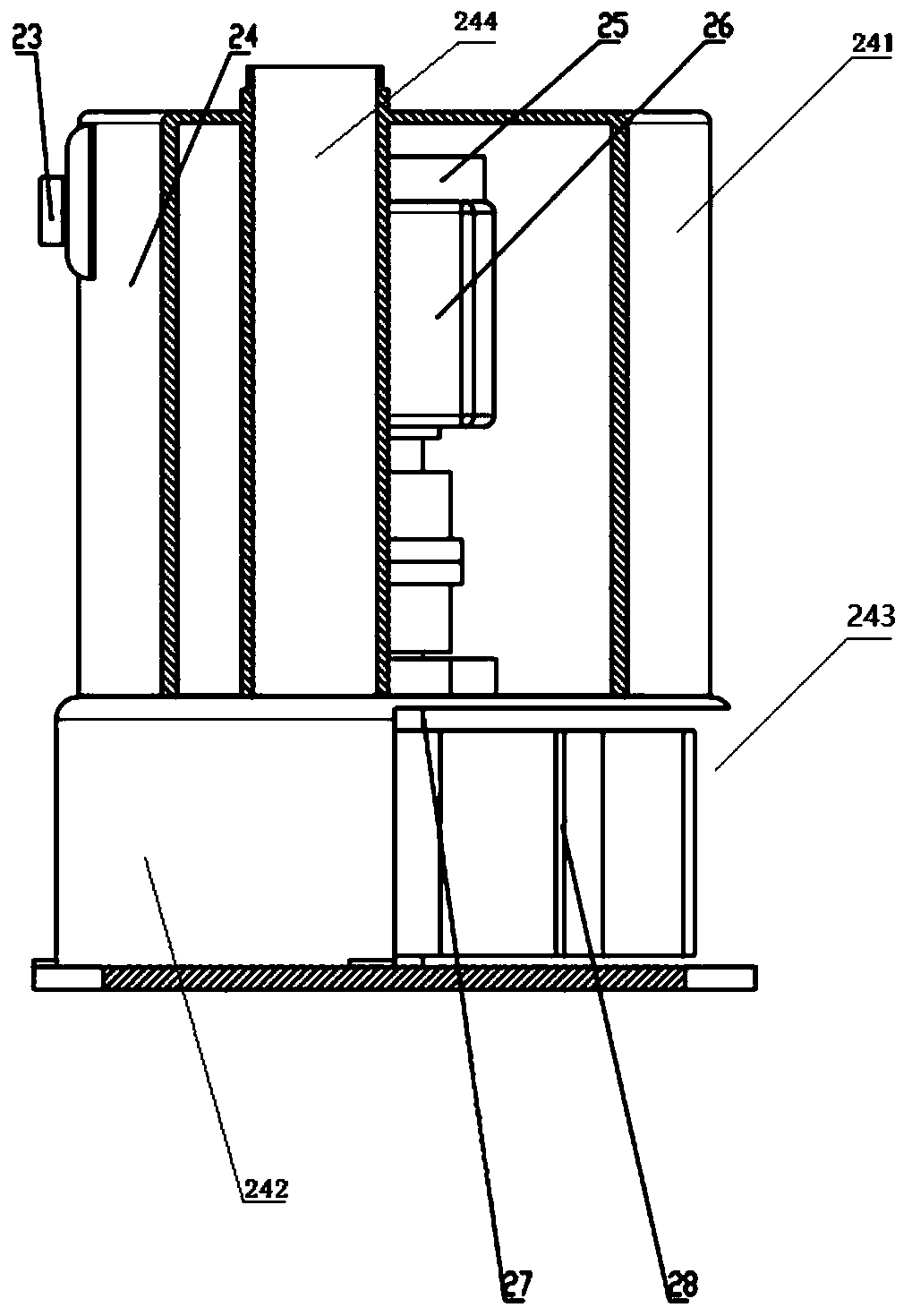

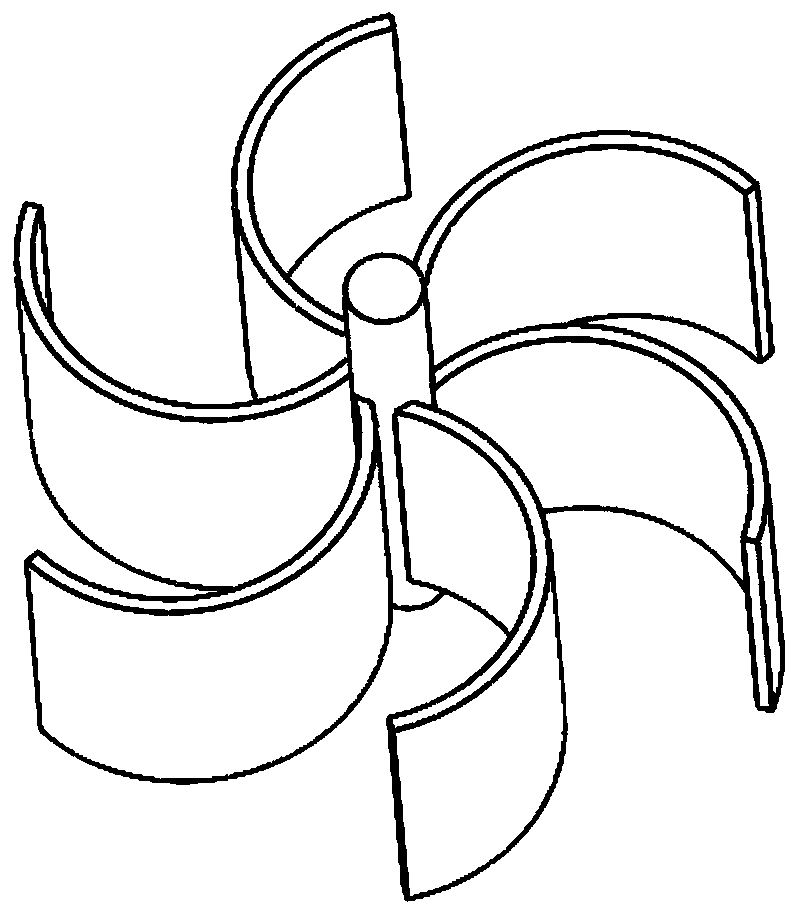

[0081] On the basis of Example 1, as a preferred embodiment: the spreading device also includes a spreader 19 connected to the discharge channel, the level of the spreader 19 is lower than the seedling divider 14, and the spreader includes The housing 24, the impeller 28 and the second motor 26 that drives the impeller to rotate, the housing 24 is provided with a horizontal partition, the housing is divided into two parts, the upper housing 241 and the base 242, the upper housing 241 and the base 242 The inner chamber of the base 242 is not connected; the impeller 28 is horizontally installed in the base 242, and the base 242 is a cylindrical shape matched with the shape and size of the impeller 28, and the side wall of the base 242 is provided with a scallop seedling. The seedling opening 243 that is sown out, the impeller shaft 27 that runs through the horizontal partition is provided on the central axis of the impeller 28; the second motor 26 is installed in the upper housin...

Embodiment 3

[0083] On the basis of Example 2, as a preferred embodiment: the spreader 19 is fixed on the ship's side by a clamping device, and the clamping device includes a connecting rod 21 and a clamping mechanism 22; one end of the connecting rod 21 is connected to The clamping mechanism 22 is connected, and the other end is fixedly connected with the spreader 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com