Counterbore hole processing equipment for electronic pcb board

A PCB board and processing equipment technology, applied in the field of countersink hole processing equipment, can solve the problems of no protection mechanism, affecting the efficiency of processing, troublesome operators, etc., and achieve the effect of improving safety, ensuring efficiency, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

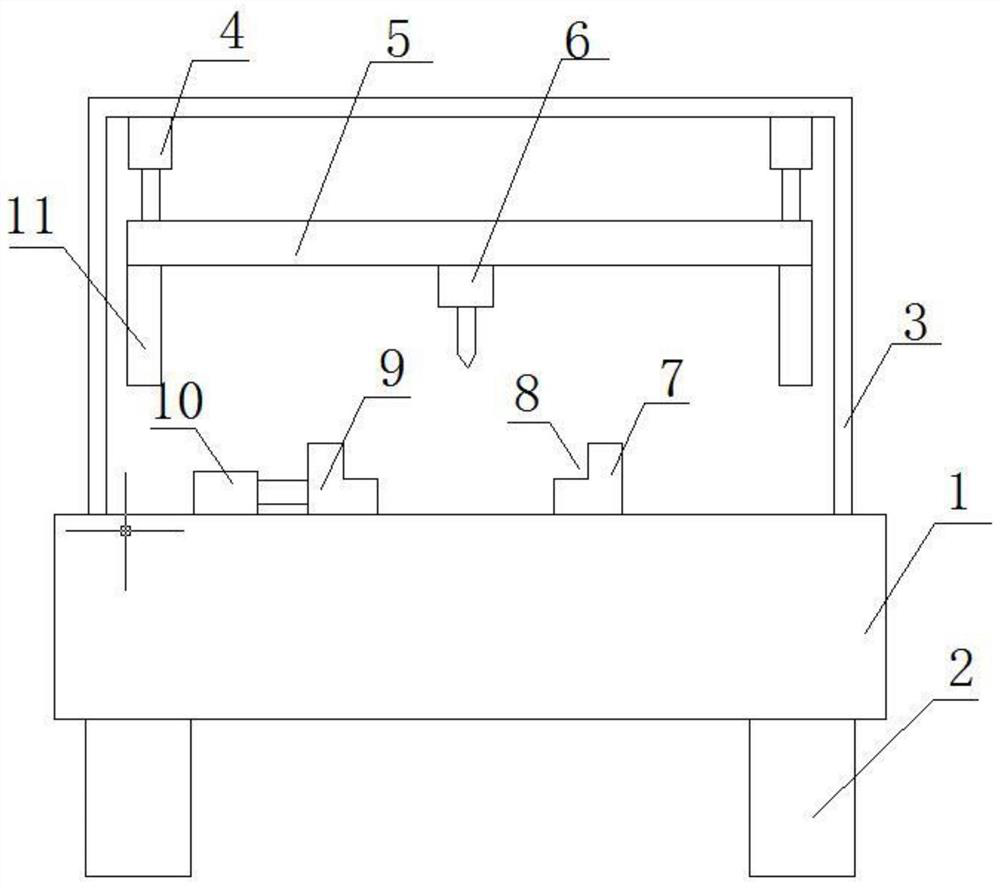

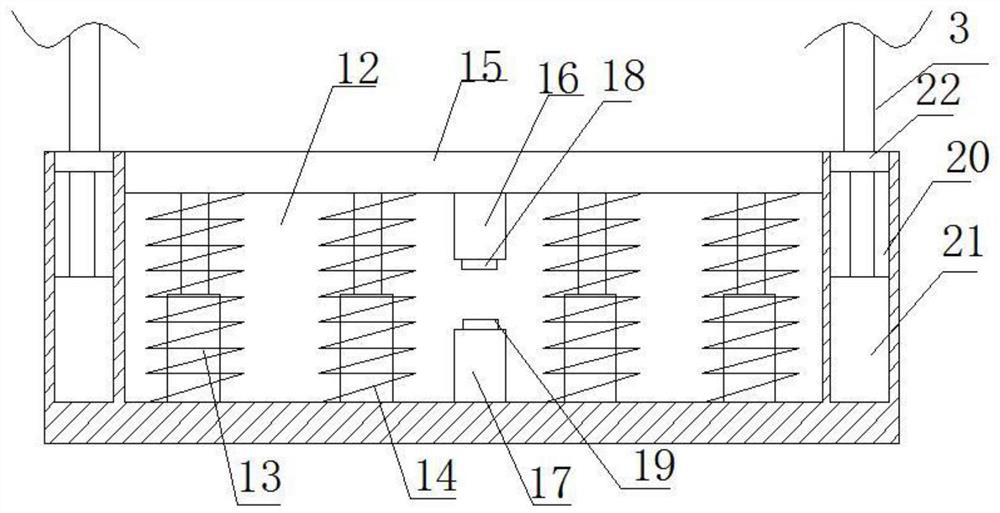

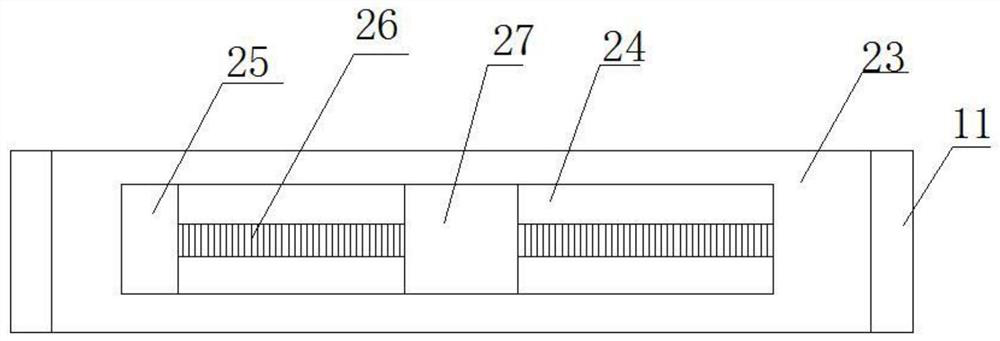

[0025] see Figure 1-3 , in an embodiment of the present invention, a countersink hole processing equipment for an electronic PCB board includes a workbench 1, a support mechanism 2 is provided at the four corners of the lower side of the workbench 1, and a machine cover 3 is arranged on the upper side of the workbench 1, The inner upper end of the hood 3 is symmetrically provided with a first electric telescopic mechanism 4, and the lower end of the first electric telescopic mechanism 4 is provided with a left and right moving mechanism 5, and a drilling mechanism 6 is installed on the left and right moving mechanism 5. , the workbench 1 is provided with a shock-absorbing chamber 12 with an upper end opening, and the inside of the shock-absorbing chamber 12 is provided with a plurality of telescopic rods 13, and the outer side of the telescopic rod 13 is provided with a shock-absorbing spring 14, and the shock-absorbing spring 14 The upper end of the shock absorbing plate 15 ...

Embodiment 2

[0029] On the basis of embodiment one, refer to Figure 4 , the support mechanism 2 includes legs 28 . The inside of the supporting leg 28 is provided with an accommodating cavity 29, the inner upper end of the accommodating cavity 29 is equipped with a fourth electric telescopic mechanism 30, and the lower end of the fourth electric telescopic mechanism 30 is equipped with a turning motor 31, two A flipping seat 32 is fixed between the turning motors 31; a support 33 is installed at the lower end of the turning seat 32, and a universal wheel 34 is installed at the lower end of the support 33, and a locking mechanism is installed on the universal wheel 34; The arrangement of the mechanism facilitates the movement of the device. When not moving, the universal wheel 34 can be received in the accommodation cavity 29 to protect the universal wheel 34 .

[0030]The upper side of the turning seat 32 is provided with a sliding chamber 35, and a fixing mechanism is installed inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com