Film cutoff device

A film cutting and cutting knife technology, which is applied in thin material processing, transportation and packaging, metal processing, etc., can solve problems such as troublesome control, cumbersome actions, and complex structures, and achieve the effect of simple structure, flexible and reliable actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

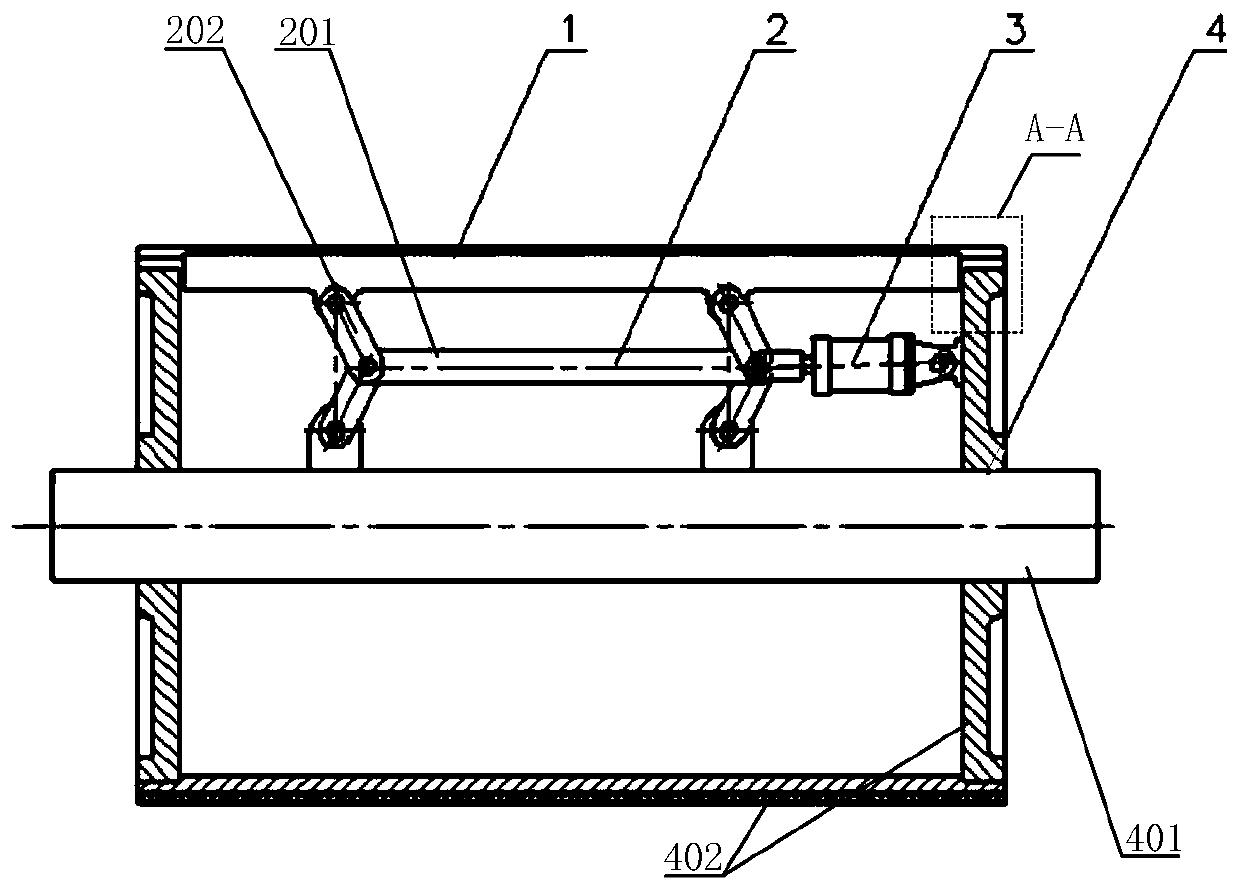

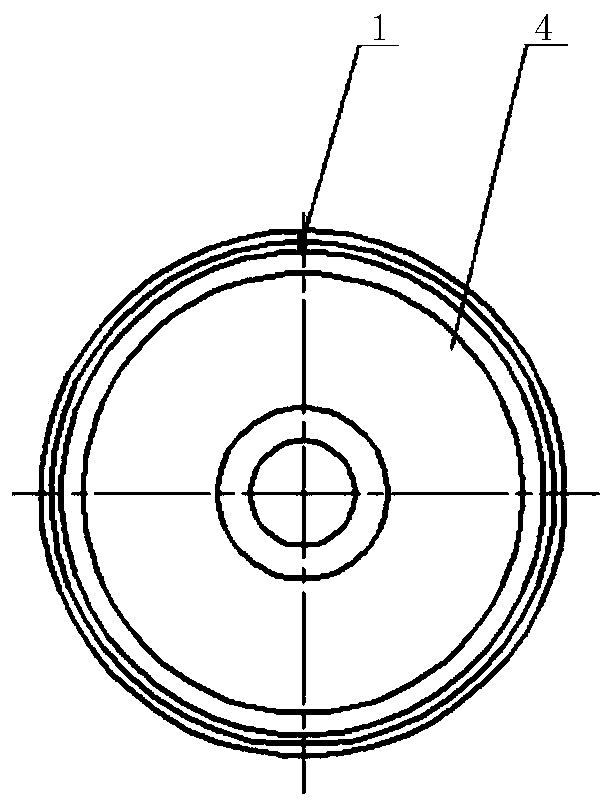

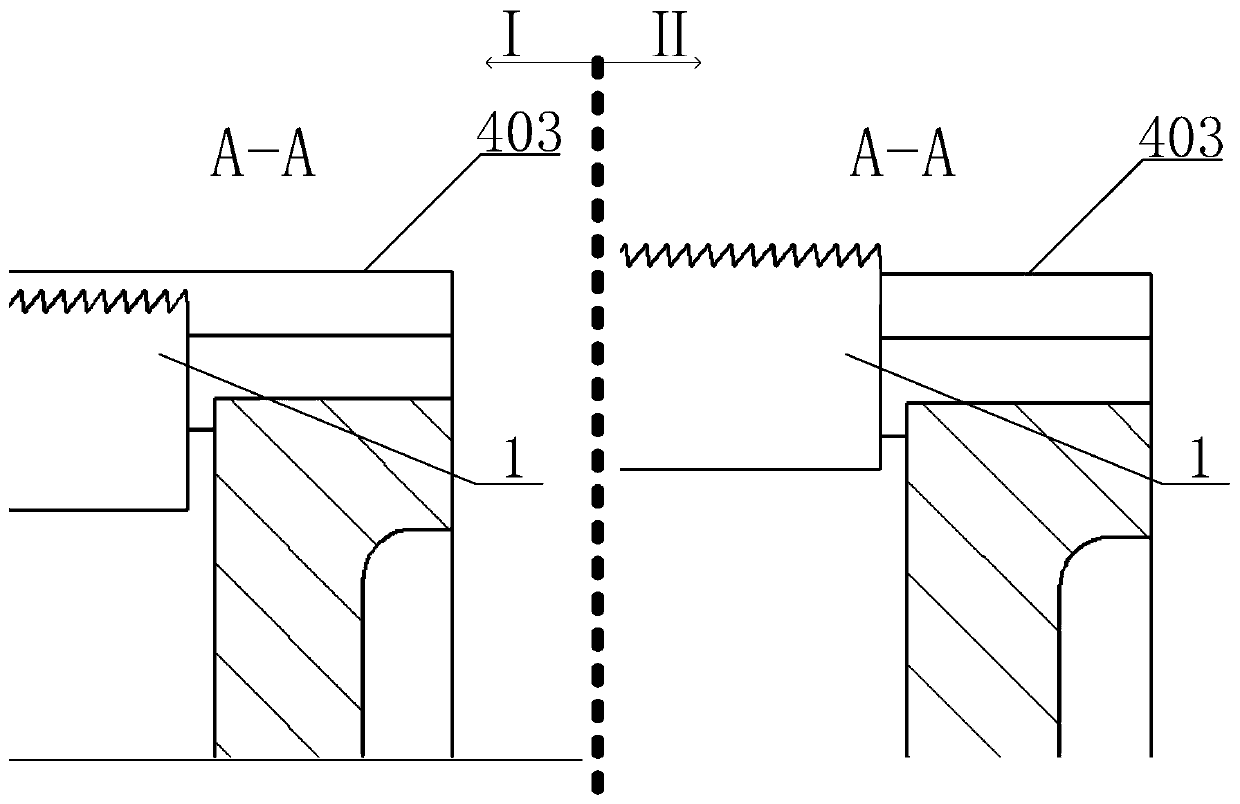

[0018] Such as figure 1 , figure 2 A film cutting device is shown, and the film cutting device includes a cutting knife 1 , a cutting knife lifting mechanism 2 , a cutting knife lifting power unit 3 and a friction roller 4 . The cutting knife 1 is installed inside the rubbing roller 4 . The friction roller 4 includes a roller shaft 401 and a roller 402 coaxially fixedly installed on the outside of the roller shaft 401. The circumferential surface of the roller 402 is provided with an axial opening for providing the radial displacement space of the cutting knife 1, and Limit displacement in other directions.

[0019] The cutting knife lifting mechanism 2 includes a connecting rod A201 and a connecting rod B202. There are four connecting rods B202, and any end of the connecting rod B202 is articulated on the connecting rod A201. The rotation of each connecting rod B202 The planes are parallel to each other; the free end of a part of the connecting rod B202 is articulated on ...

Embodiment 2

[0025] A film cutting device, comprising a cutting knife 1 , a cutting knife lifting mechanism 2 , a cutting knife lifting power unit 3 and a friction roller 4 . The friction roller 4 includes a roller shaft 401 and a roller 402 coaxially fixedly installed on the outside of the roller shaft 401. The circumferential surface of the roller 402 is provided with an axial opening for providing the radial displacement space of the cutting knife 1, and Limit displacement in other directions.

[0026] The cutting knife lifting mechanism 2 includes a connecting rod A201 and a connecting rod B202. There are six connecting rods B202 in total, and any end of the connecting rod B202 is movably hinged on the connecting rod A201. The rotation of each connecting rod B202 The planes are parallel to each other; the free end of a part of the connecting rod B202 is articulated on the roller shaft 401, and the free end of the other part of the connecting rod B202 is articulated on the cutting knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com