A long-acting sealant for sealing high-angle cracks and its preparation method

A sealing agent, high-angle technology, applied in the direction of chemical instruments and methods, reagents, drilling compositions, etc., can solve the problem of difficult to block high-angle fractures, uncontrollable fracture height, and different performance of plugging agents problem, to achieve the effect of long effective plugging time, low cost and less harsh reaction conditions

Active Publication Date: 2022-06-03

PETROCHINA CO LTD

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to overcome the deficiencies of the above-mentioned prior art, to provide a long-acting sealant for sealing high-angle fractures and its preparation method, which overcomes 1 in the prior art: adding fluid loss control agents to reduce the influence of natural fractures , the disadvantage is that it cannot overcome the problem of out-of-control fracture height caused by the existence of natural fractures or faults; 2: Inject temporary plugging agents in the front of the fractures to seal natural fractures. The disadvantage is that the performance of plugging agents on the market varies, and most of them are temporary plugging pressure 3: Even if the fractures are blocked during fracturing, the formation water will rush into the oil layer after the plugging agent fails after fracturing and a large amount of water will come out, and the stimulation effect is poor, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

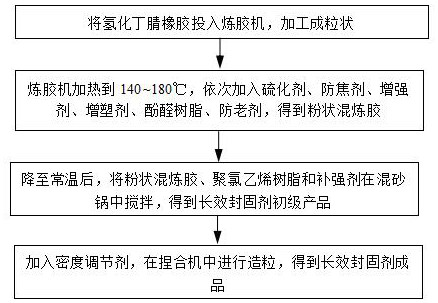

The invention discloses a long-acting sealing agent for sealing high-angle cracks and a preparation method, which comprises hydrogenated nitrile rubber, phenolic resin, polyvinyl chloride resin, plasticizer, reinforcing agent, density regulator, reinforcing agent, Vulcanizing agent, anti-scorch agent and anti-aging agent, wherein the weight percentage of each component is: 33~42% hydrogenated nitrile rubber, 24~35% phenolic resin, 13~22% polyvinyl chloride resin, 3~8% % plasticizer, 2~6% reinforcing agent, 1~5% density regulator, 1~3% reinforcing agent, 1~3% vulcanizing agent, 0.2~1% anti-scorch agent, 0.2~0.8% anti-aging agent. The present invention proposes a long-acting sealant for sealing high-angle fractures aimed at the fault-block reservoirs in thrust belts at the western edge of the Ordos Basin. The long-acting sealant can consolidate high-angle fractures with different openings or Faults overcome the problems of fracturing fluid leakage and fracture height uncontrollable caused by natural fractures or fault penetrations that cannot be solved by conventional methods.

Description

A long-acting sealing agent for plugging high-angle cracks and preparation method thereof technical field The invention belongs to the chemical technology field of petroleum industry, relate in particular to a kind of long-acting seal of plugging high-angle cracks Solidifying agent and preparation method. Background technique [0002] The fault-block reservoir represented by the thrust belt in the western margin of the Ordos Basin requires hydraulic pressure due to its tight physical properties. However, high-angle natural fractures and micro-faults develop, penetrating the barrier layer up and down, and in hydraulic fracturing During the process, the developed natural fractures and faults will lead to a large amount of fracturing fluid filtration and uncontrolled fracture height, which will make the fracturing effective. The results are poor and even lead to the failure of fracturing construction. For reservoirs with high-angle fractures, there is currently no effect...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/44C09K8/48C08L15/00C08L61/06C08L27/06C08K13/02C08K3/30C08K3/26C08K3/04C08K3/36

CPCC09K8/426C09K8/44C09K8/48C08L15/005C08L2201/08C08L2205/03C08K2003/3045C08K2003/265C08L61/06C08L27/06C08K13/02C08K3/30C08K3/26C08K3/04C08K3/36Y02P20/141

Inventor 李川张矿生唐梅荣张翔董立全李昌恒刘怡王泫懿陈强向奎

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com