Hydrocracking method for increasing yield of heavy naphtha and jet fuel fractions

A hydrocracking and jet fuel technology, which is applied in the field of hydrocracking of distillate oil or secondary processed oil to produce heavy naphtha and jet fuel fractions, can solve the problem of low selectivity, heavy naphtha and jet fuel component recovery The problems of low efficiency and short operation period of the device are achieved, and the effects of high ring-opening selectivity, reduced density, and increased hydrogen content are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

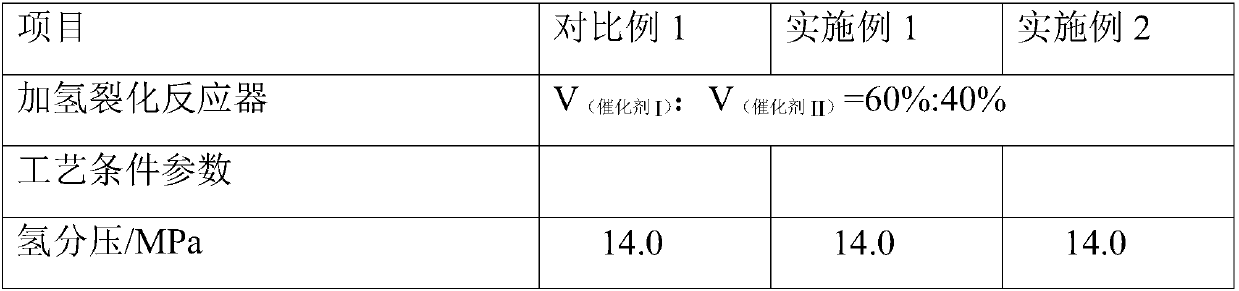

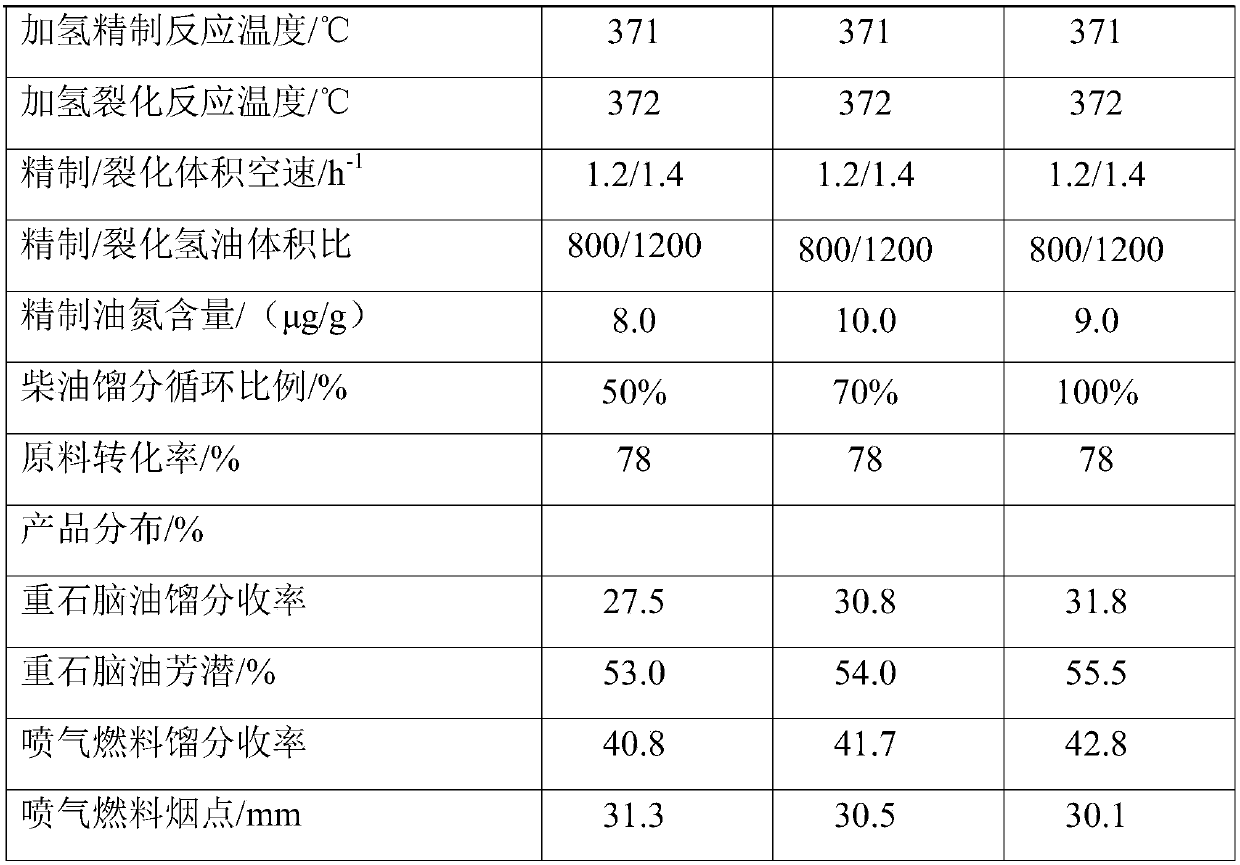

Embodiment 1

[0071] In embodiment 1, based on the diesel fraction as a whole, the mass fraction of the diesel fraction recycled back to the hydrocracking reaction zone is 70% (the diesel fraction circulation ratio is 70%), and the yield of the resulting product heavy naphtha fraction and jet fuel fraction 30.8% and 41.7%, respectively.

Embodiment 2

[0072] In embodiment 2, based on the diesel fraction as a whole, the mass fraction of the diesel fraction recycled back to the hydrocracking reaction zone is 100% (the diesel fraction circulation ratio is 100%), and the yield of the resulting product heavy naphtha fraction and jet fuel fraction is 100%. 31.8% and 42.8%, respectively.

[0073] It can be seen that, under the high raw material conversion rate, adopting the preferred diesel oil fraction circulation ratio of the present invention, the total yield of the obtained product heavy naphtha fraction and jet fuel is higher.

Embodiment 5

[0085] After the raw material B is mixed with hydrogen, it passes through the hydrofinishing reaction zone and the hydrocracking reaction zone, and successively contacts with the hydrofinishing catalyst, hydrocracking catalyst C and hydrocracking catalyst D to react, and the obtained reaction product is separated to obtain pumice Naphtha fraction, heavy naphtha fraction, jet fuel fraction, diesel fraction and tail oil fraction, the cut point between diesel fraction and tail oil fraction is 320°C, based on the diesel fraction as a whole, recycled back to the hydrocracking reaction zone The mass fraction of the diesel fraction is 100%, and the conversion rate of the control raw material is 79%. Catalyst grading scheme, process condition parameters and product yield and property data are listed in Table 4.

[0086] From the data in Table 4, it can be seen that the yields of heavy naphtha and jet fuel obtained in Example 5 were 34.0% and 40.5%, respectively, and the hydrocracking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com