Multidirectional displacement composite plate type telescopic device for highway bridge

A technology for highway bridges and displacement devices, applied in bridges, bridge construction, bridge parts, etc., can solve problems that affect service life and traffic safety, loose and fall off stuck steel plates, and thin anchorage systems, etc., to achieve convenient parameter adjustment and structural stability , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

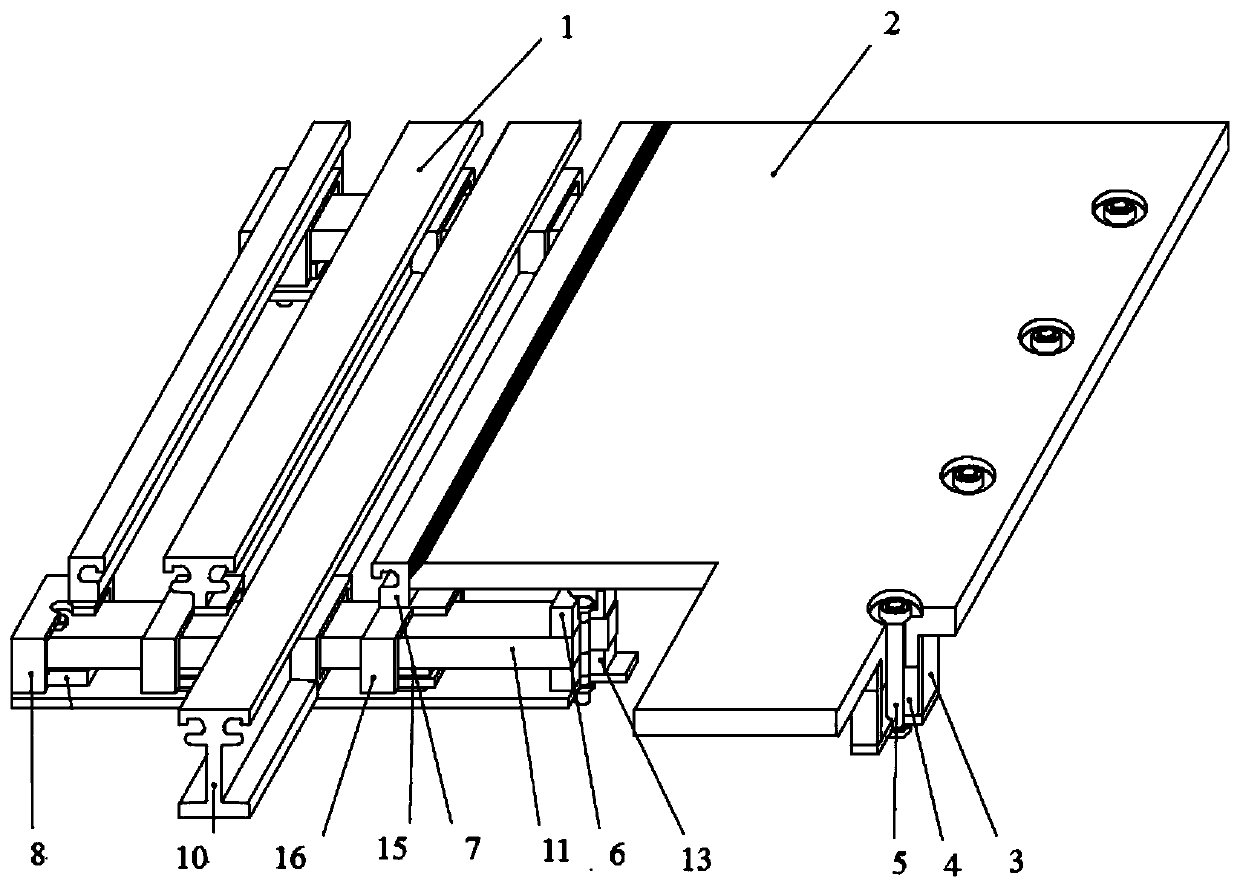

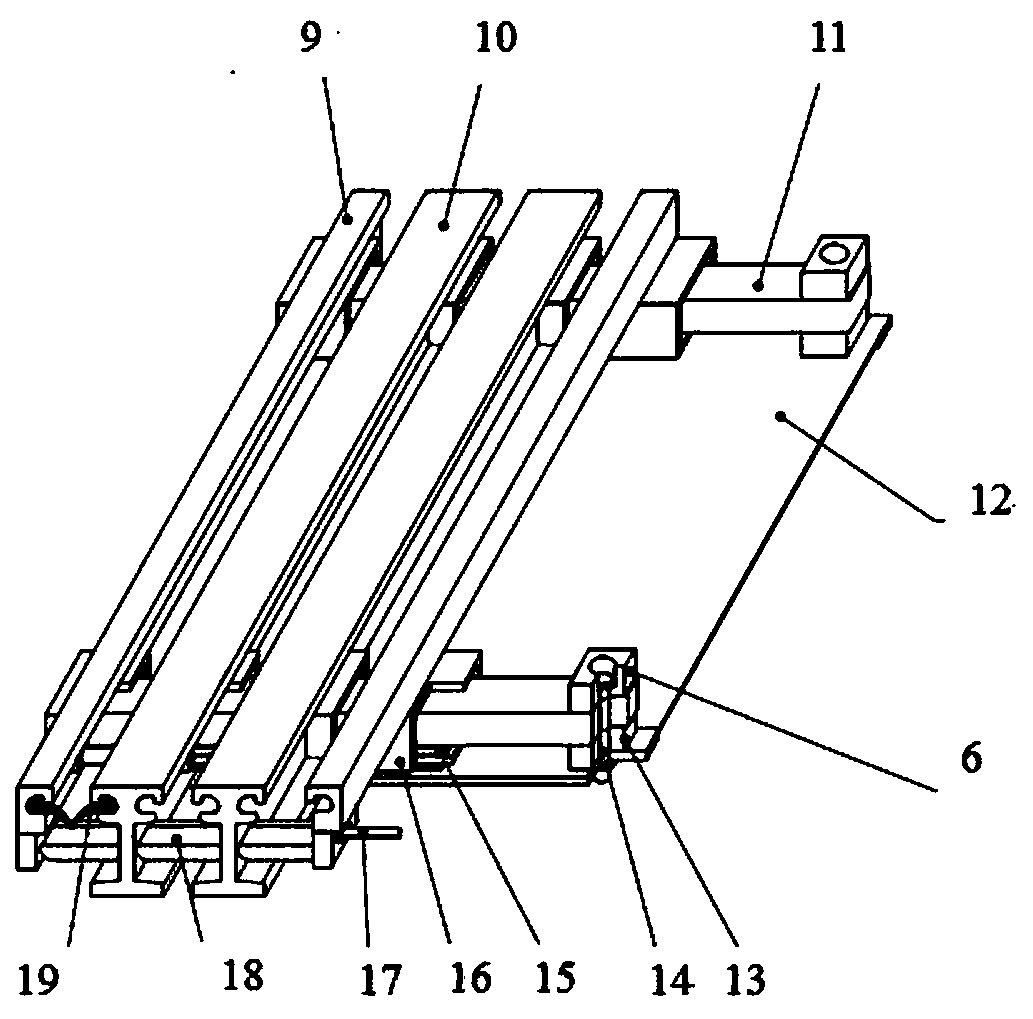

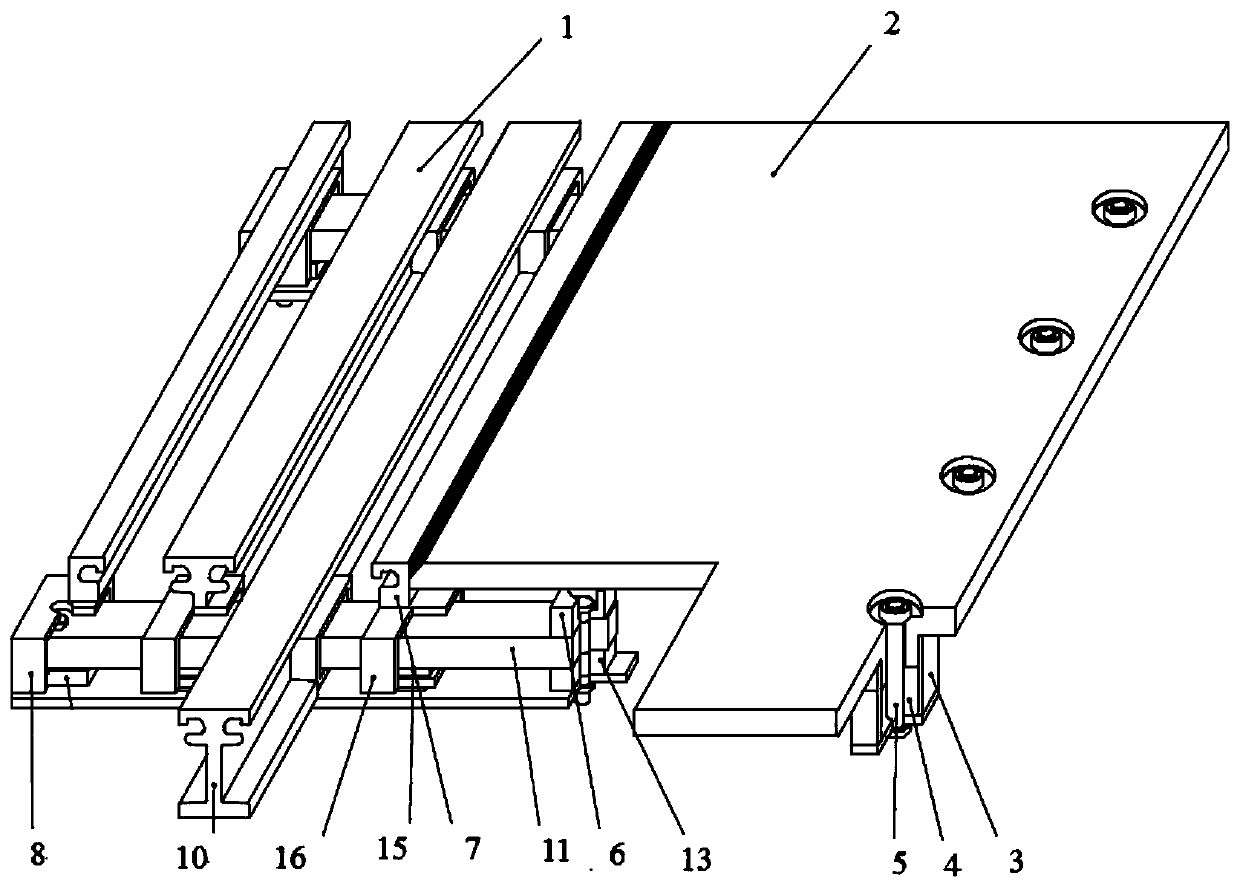

[0021] Such as figure 1 (Schematic diagram of the structure of the multi-directional displacement composite plate telescopic device), the device is mainly composed of a displacement device 1 and a fixed plate 2, and the fixed plate 2 is welded to the inner side beam 7 of the displacement device 1 by welding. One end of the fixed plate 2 is welded flush with the upper surface of the inner side beam 7 of the displacement device to form an integral structure, the inner side is formed by a supporting block 6 as a force transmission fulcrum, and the PTFE plate on the upper surface of the supporting block 6 and the fixed plate 2 form a sliding support point. The other side of the fixed plate 2 is connected to the bridge deck through the bolts on the anchor assembly. The anchor assembly is composed of the anchor box 3, the compression rubber block 4 and the connecting bolt 5. The fixed plate 2 is embedded in the anchor box 3 through the boss at the bottom. The bottom of the boss and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com