Support-free construction process for steel-concrete composite beam

A construction technique and technology without support, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of complex structure of construction devices without support, increase the burden of temporary support foundation, endanger the safety of the whole bridge, etc., and achieve light weight, The effect of reducing construction costs and reducing impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

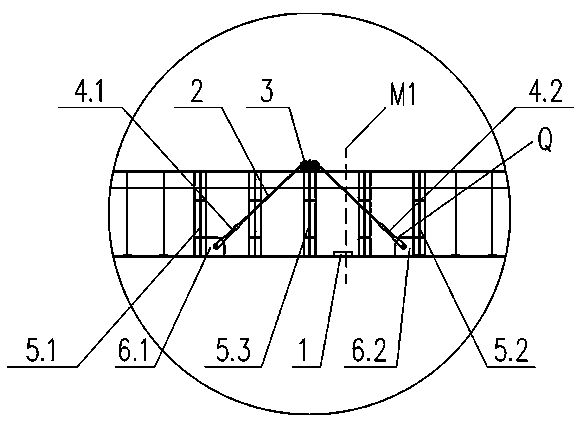

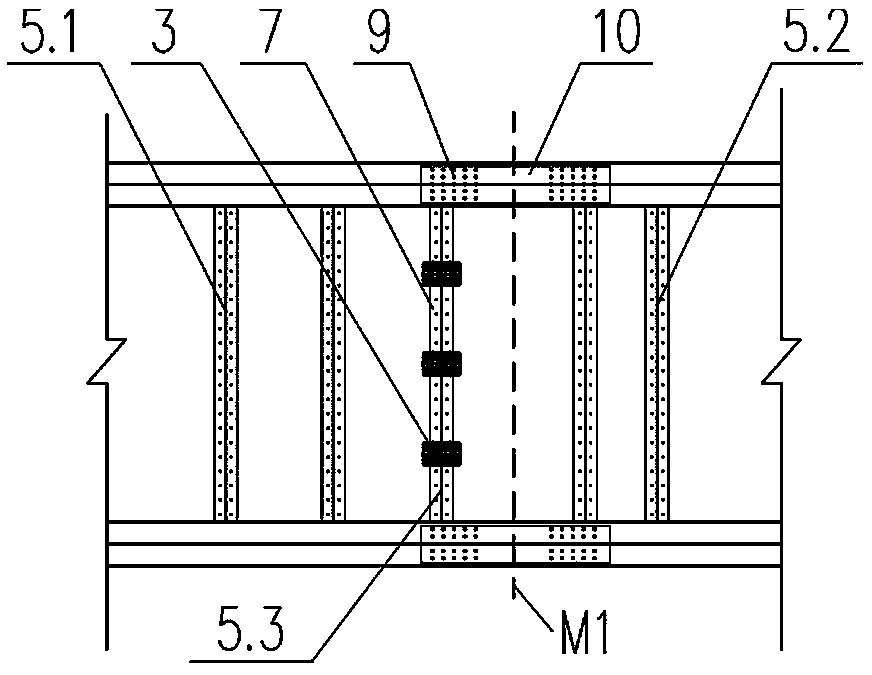

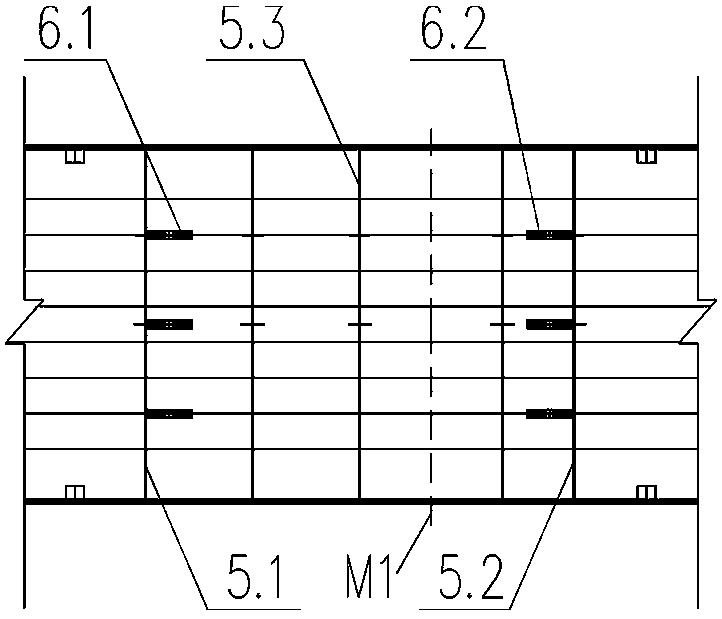

[0025] Such as figure 1 In the bridge shown, the left and right ends are the installed beam section L1 and the installed beam section L2, the middle is the hoisting beam section L3 hoisted by cranes and other equipment, the hoisting beam section L3 and the installed beam section L1, and the installed beam section L2 The assembly surfaces are M1 and M2 respectively. When installing the hoisting beam section L3, the steel-concrete composite beam without support construction process described in the present invention is adopted. In the following, the assembling surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com