Grouting device for road bridge construction

A technology of bridge construction and grouting device, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of affecting the efficiency of grouting, agglomeration and solidification of the slurry, etc., to ensure safety, high quality of discharge, safety high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

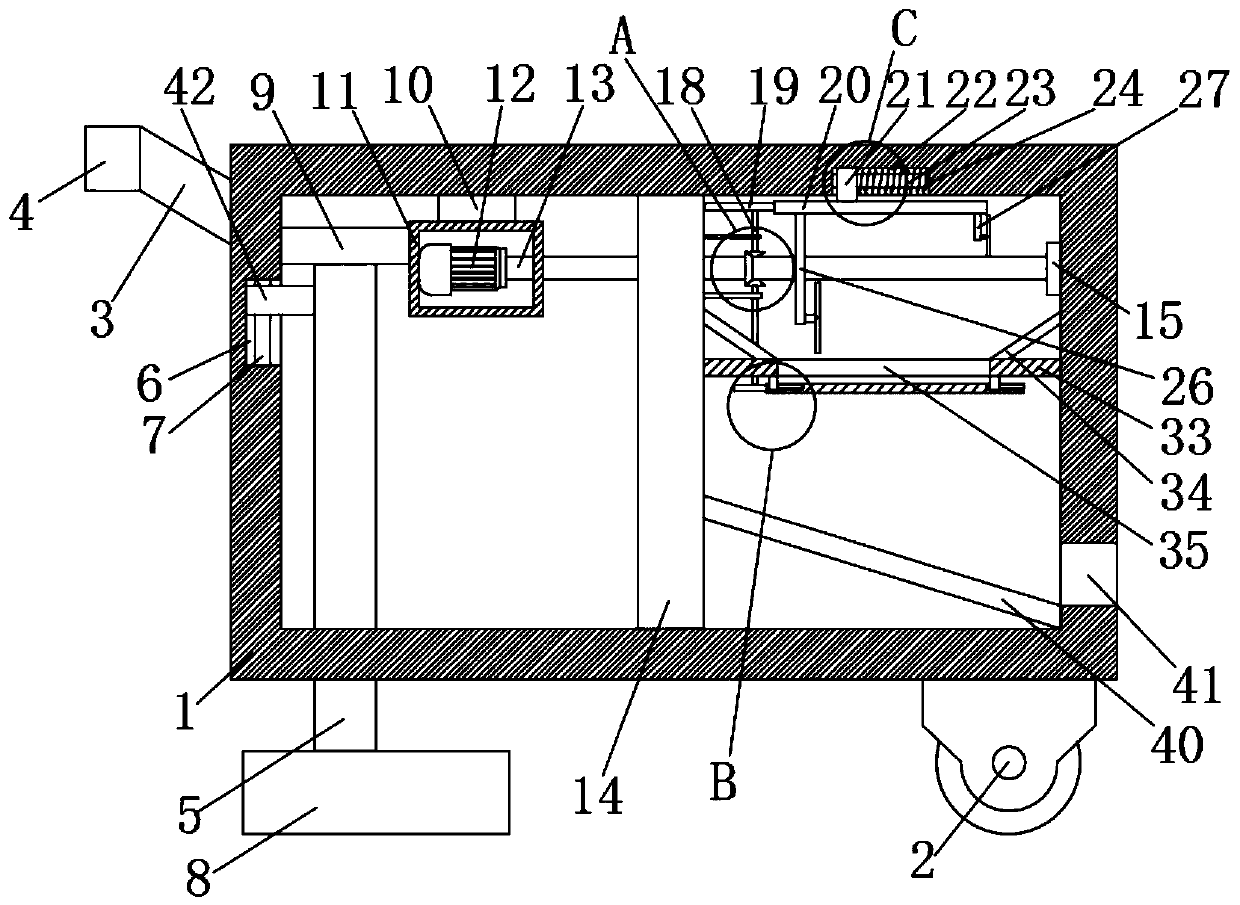

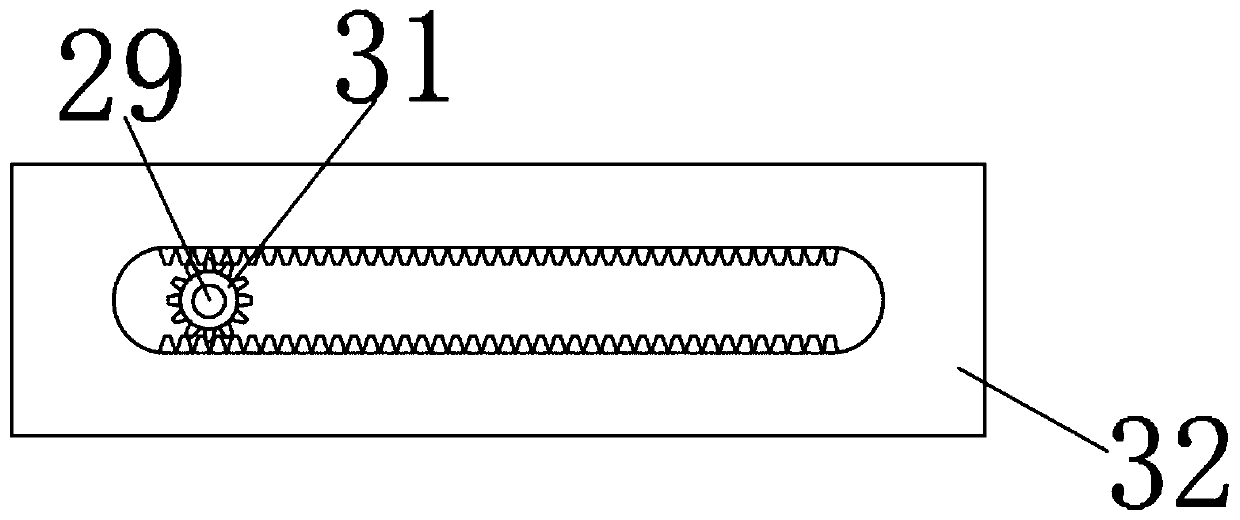

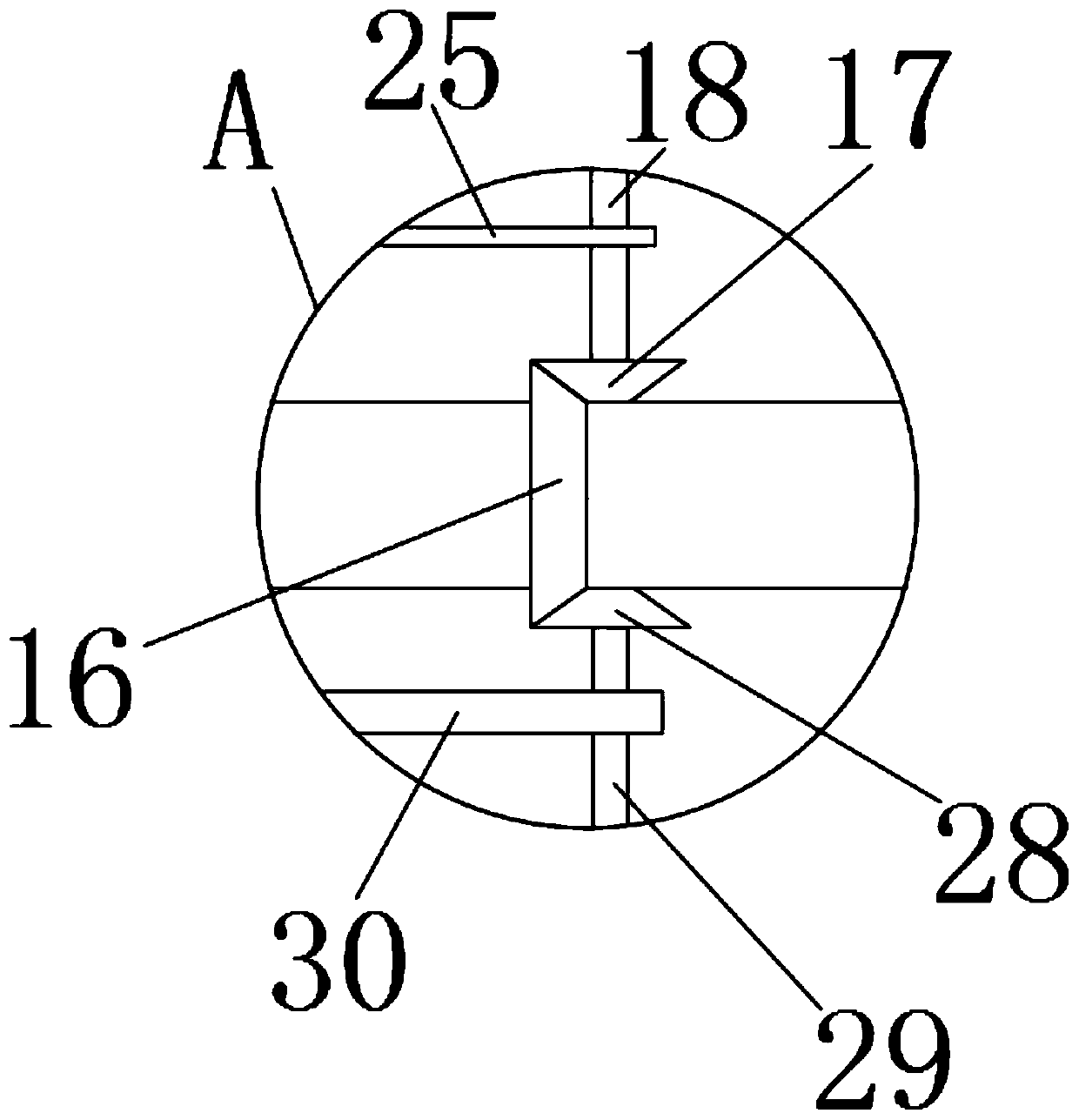

[0027] refer to Figure 1-5 , a grouting device for road and bridge construction, comprising a box body 1, a bottom wheel 2 is fixedly installed on the bottom of the box body 1, two fixed plates 3 are fixedly fixedly installed on one side of the box body 1, and two fixed plates 3 are fixed on the bottom of the box body 1. The same handle 4 is fixedly installed, and a pillar 5 is slidably installed on one side of the inner wall of the box body 1. A bottom plate 8 is fixedly installed on one end of the pillar 5, and a circuit board 9 is fixedly installed on the other end of the pillar 5. The top inner wall of the box body 1 A drive motor 12 is fixedly installed on the top, and one end of the drive shaft 13 is fixedly installed on the output shaft of the drive motor 12. Plate 14, one end of the transmission rod 18 is rotatably installed on the drive shaft 13, the transmission rod 18 is rotatably mounted on one side of the partition 14, the other end of the transmission rod 18 is ...

Embodiment 2

[0038] refer to Figure 1-5 A grouting device for road and bridge construction, comprising a box body 1, the bottom of the box body 1 is fixedly equipped with a bottom wheel 2, which facilitates the movement of the whole device, and one side of the box body 1 is symmetrically fixedly installed with two fixed plates 3, The same handle 4 is fixedly installed on the two fixed plates 3, which is convenient for the control of the device. A pillar 5 is slidably installed on one side of the inner wall of the box body 1, and a bottom plate 8 is fixedly installed on one end of the pillar 5, and the other end of the pillar 5 is fixed. A circuit board 9 is installed, a drive motor 12 is fixedly installed on the top inner wall of the box body 1, an end of the drive shaft 13 is fixedly installed on the output shaft of the drive motor 12, and the other end of the drive shaft 13 is rotatably installed on one side of the box body 1. On the side inner wall, a partition 14 is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com