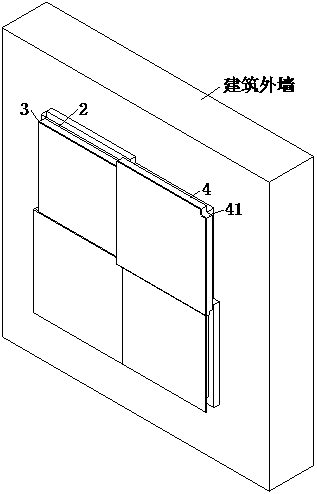

Building outer wall composite insulation board

A technology for composite thermal insulation and building exterior walls, which is applied in thermal insulation, construction, building components, etc. It can solve problems affecting the function of thermal insulation boards, potential safety hazards, loosening and even falling off of thermal insulation boards, and achieve the purpose of maintaining sealing effects, maintaining service life, and improving The effect of thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

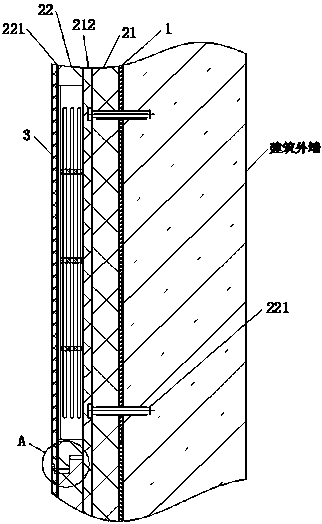

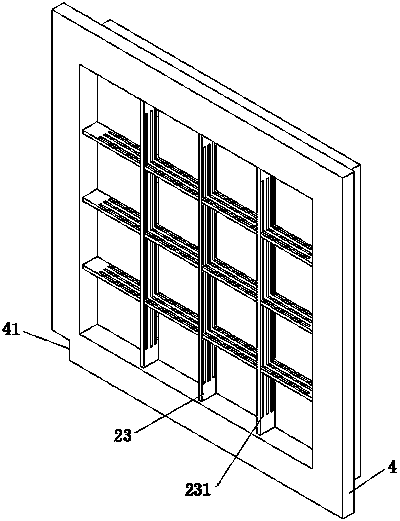

[0027] As an embodiment of the present invention, a rubber pad 212 is arranged between the base layer 21 and the filler layer 22, and the rubber pad 212 wraps the expansion bolt 211 on the base layer 21; the filler layer 22 passes through the rubber pad 212 It is bonded and fixed on the base layer 21; during work, when the filler layer 22 deforms with the change of the external environment, the flocculent thermal insulation material arranged in the cavity of the filler layer 22 cooperates with the air in between to buffer the base layer. Influenced by the deformation of the bottom layer 21, the base layer 21 and the filler layer 22 are fixed by direct bonding, and different deformations will affect the bonding after long-term use, thereby weakening the bonding of the filler layer 22 on the base layer 21. Fixing effect; by being arranged on the rubber pad 212 bonded between the base layer 21 and the filler layer 22, the elastic deformation produced on the upper and lower surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com