Rope coring drilling tool suitable for large-caliber horizontal engineering geological exploration

A technology for engineering geology and coring drilling tools, which is applied in the direction of extracting undisturbed core devices, drill pipes, drill pipes, etc., and can solve the problem of reduced work reliability and stability, deadlocking of the ejector plate and ejector head, and increased drill sticking The risk of accidents and other issues, to achieve the effect of rapid and reliable shrinkage performance, increase the area of the water ring, and avoid the risk of normal salvage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

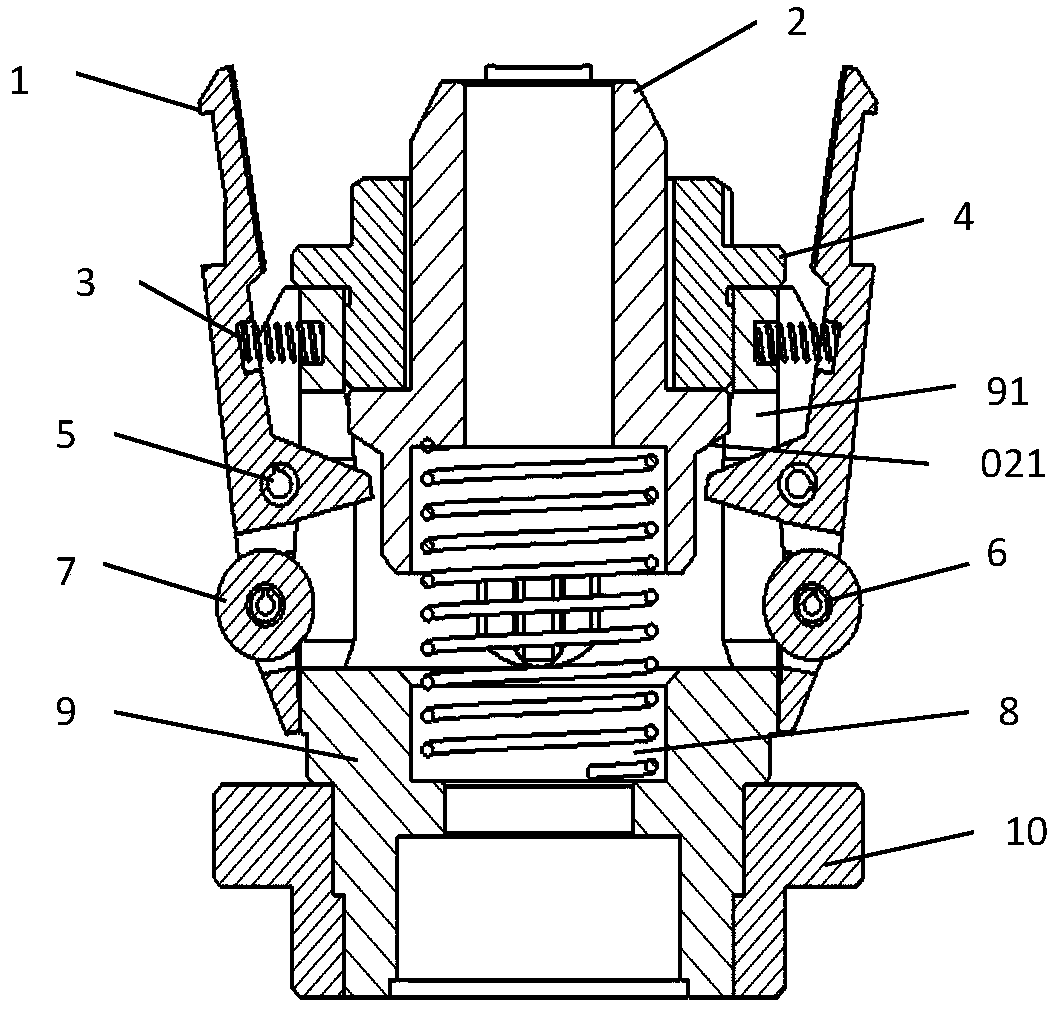

[0025] Such as Figure 1-7 As shown, the present invention includes a bullet positioning assembly and a salvage push device, and the salvage push device includes a lifting head 11, a cylindrical pin 12, a joint 13, a lock nut 14, a push mechanism 15, and a catch mechanism 16; The slider 11 is hinged to the upper part of the joint 11 through a cylindrical pin 12, the bottom of the joint 11 is provided with a catch mechanism 13 and a push mechanism 14, the push mechanism 14 is located in the catch mechanism 13, and the push mechanism 14 is screwed to the central hole of the joint 11, A locking nut 12 is provided on the pushing mechanism 14 .

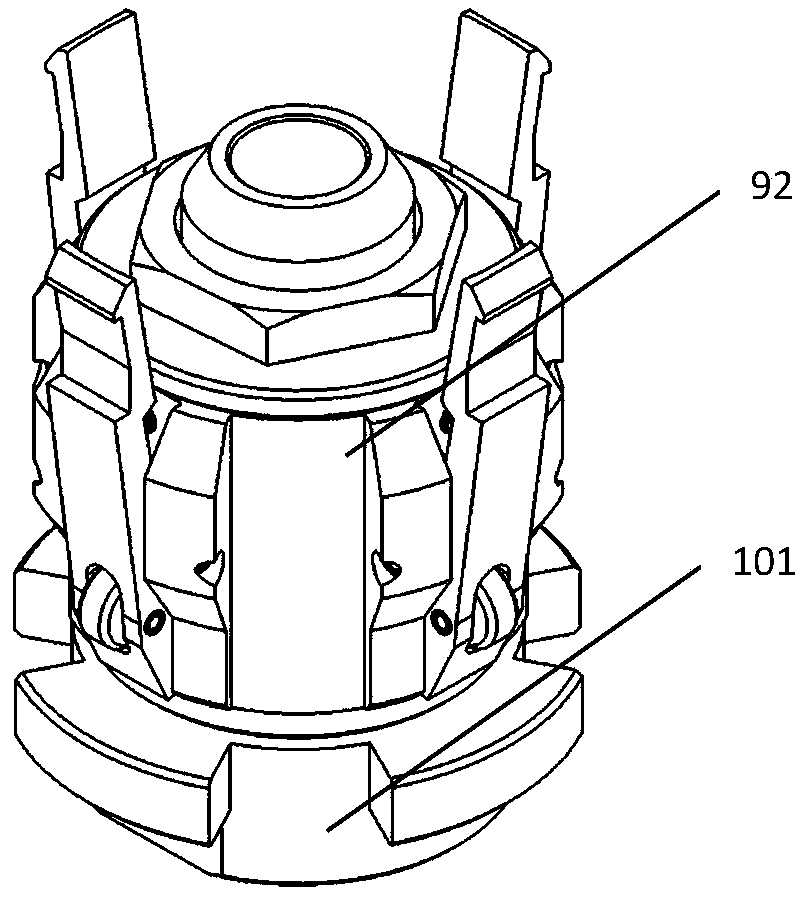

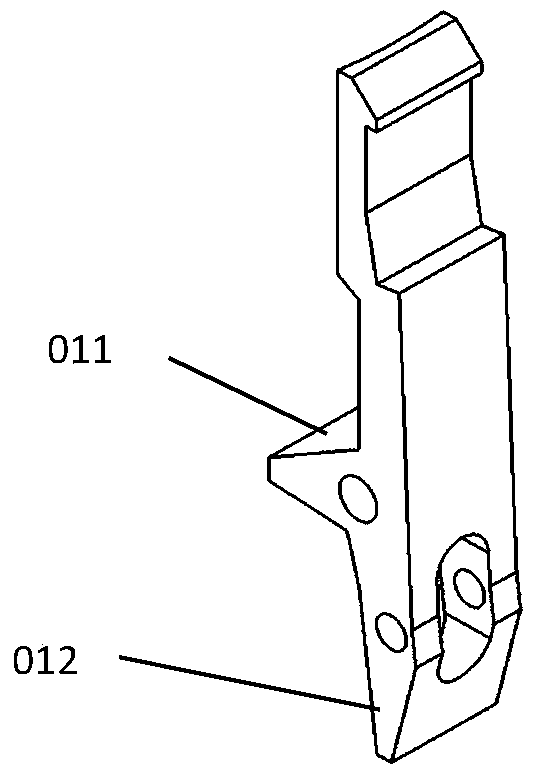

[0026] The snap positioning assembly includes claw 1, pressure sleeve 2, claw spring 3, gland 4, roller 7, pressure sleeve spring 8, claw bracket 9 and suspension ring 10; the sides of the claw bracket 9 are evenly distributed Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap