Special heating pipeline robot for coalbed methane thermal recovery

A pipeline robot and heating pipeline technology are applied in the field of special heating pipeline robots for thermal mining of coalbed methane, which can solve problems such as application effect limitation, and achieve the effects of easy operation, improved mining efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

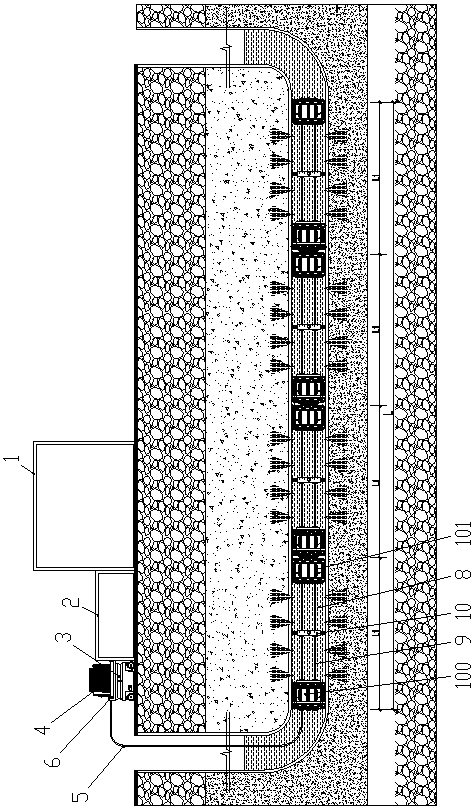

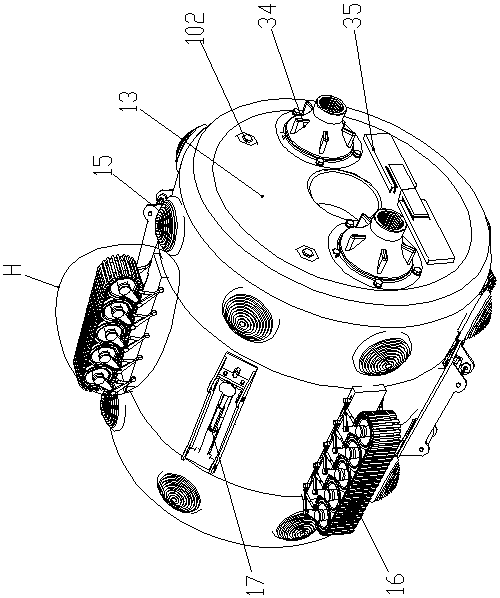

[0041] Such as Figure 1-9 As shown, the special heating pipeline robot for coal-bed methane thermal recovery of the present invention includes a ground reel 3, a generator 2, a ground control center 1, and several groups of hollow pipeline robot groups. The ground reel 3 is provided with a smart cable winch 4 , The smart cable winch 4 is wound with a high temperature resistant tensile cable 5, the outlet end of the smart cable winch 4 is provided with a first tension sensor 6; n groups of hollow pipeline robot groups are assembled, one end of the high temperature resistant tensile cable 5 is connected to the power generation The machine 2 is connected, the other end of the high temperature resistant tensile cable 5 is connected to the hollow pipe robot group at the rear; the smart cable winch 4, the first tension sensor 6, the generator 2 and all the hollow pipe robot groups pass through The control line is connected to the ground control center 1.

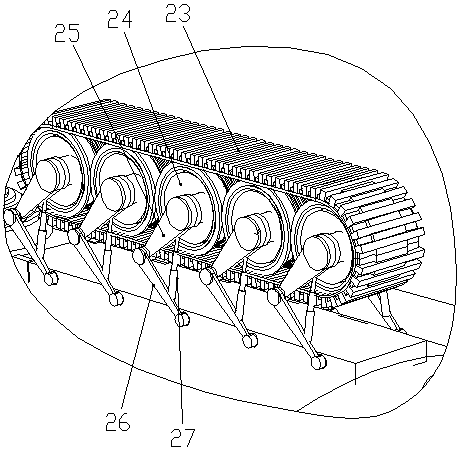

[0042] The hollow pipeline ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap