Automotive trim door plate multifunctional composite testing fixture and using method thereof

A car interior and multi-function technology, which is applied in the field of multi-functional composite inspection tools for car interior door panels, can solve the problems that the three-coordinate full-scale detection function of car interior door panels cannot be realized, achieve consistent installation status, and reduce floor space , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

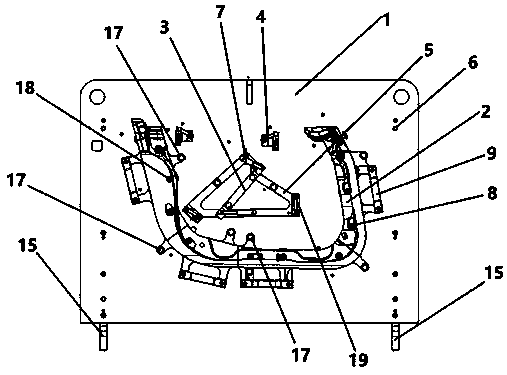

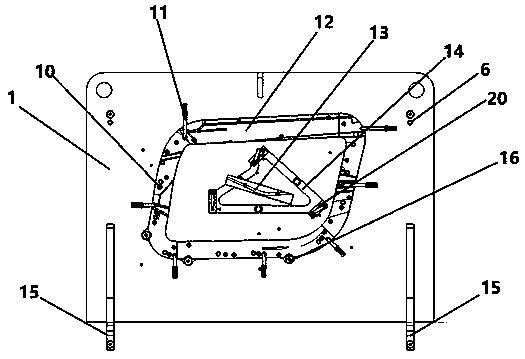

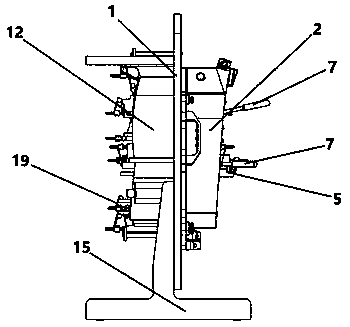

[0060] Such as Figure 1 to Figure 5As shown, the technical solution adopted by the multifunctional composite inspection tool for automobile interior door panels according to the present invention includes two left and right inspection tool bases 15, and the left and right two inspection tool bases 15 are connected with the inspection tool base plate 1. The door panel iron door sheet metal profiling block 2 is installed on the front of the inspection tool bottom plate 1, and the door panel iron door sheet metal profiling block 2 is a profiling simulation block that completely simulates the body iron door sheet metal. The inner wall and the outer wall of the profiling block 2 are respectively provided with three front lugs integrated with the door panel iron door sheet metal profiling block 2, and each front lug is provided with a screw hole and the door panel iron door is installed therein. Sheet metal analog block lock nut 17, 4 analog block handles 9 that are convenient to t...

specific Embodiment approach 2

[0064] Such as Figure 4 As shown, one of the methods of using the multifunctional composite inspection tool for automotive interior door panels as described in Embodiment 1 is that when preparing for the matching detection of the automotive interior door panel assembly and the front sheet metal of the vehicle body, the door panel substrate Remove the main positioning block 5 and the 10 positioning locking mechanisms 8, align the front of the vehicle interior door panel assembly to be tested on the door panel iron door sheet metal profiling block 2 in front of the inspection tool bottom plate 1, and place the vehicle The buckle of the interior door panel assembly is snapped into the profiling hole 18 of the iron door sheet metal, and the product is hung up by the YZ direction limit block 42 on the Y and Z direction limit mechanism 4, and the elastic piece 45 is pressed by the upper end positioning The product is compacted, and then the product is compacted by measuring the pos...

specific Embodiment approach 3

[0066] Such as Figure 5 As shown, the second method of using the multifunctional composite inspection tool for an automotive interior door panel as described in Embodiment 1 is to place the main positioning block 5 And the iron door sheet metal profiling block 2 of the door panel is removed, and it can be seen that a positioning locking mechanism mounting seat 21 is installed on the inspection tool bottom plate 1, and the positioning locking mechanism 8 is installed on the positioning locking mechanism mounting seat 21, and the to-be-tested The front of the automobile interior door panel is aligned and installed on the positioning locking mechanism 8 in front of the bottom plate 1 of the inspection tool, and the position of the product to be tested is adjusted so that the product to be tested can be smoothly loaded according to the positioning position on the inspection tool, and then passed 10 positioning and locking mechanisms 8 compress the product to be tested, hang and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com