Temperature measurement calibration method based on PT1000 temperature sensor

A technology of temperature sensor and calibration method, which is applied in the direction of thermometers, thermometer testing/calibration, thermometers, etc. that are directly sensitive to heat/magnetic components, and can solve problems such as inability to guarantee correct control systems and large errors, and achieve easy management , Improve the temperature measurement accuracy and reduce the error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

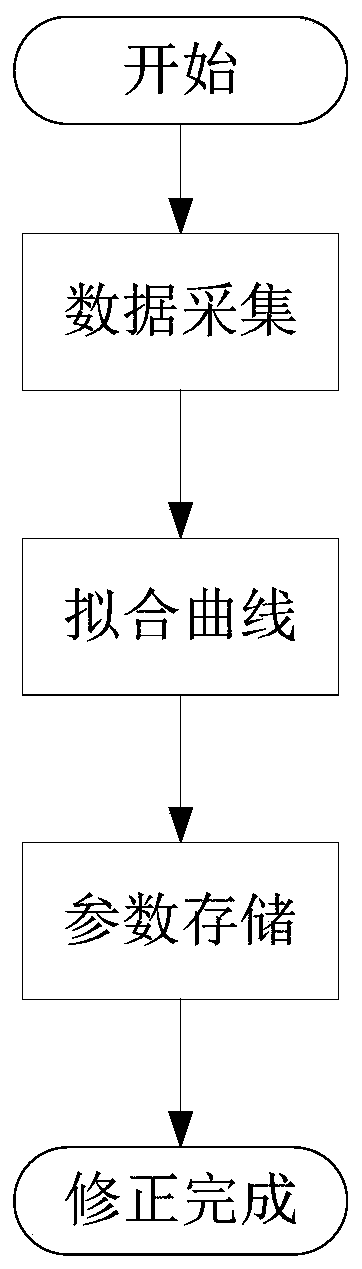

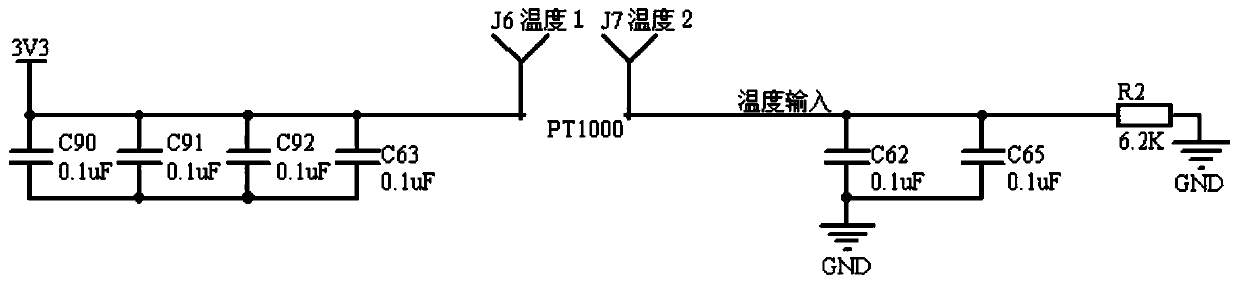

[0055] combine figure 1 , a kind of temperature measurement and calibration method based on PT1000 temperature sensor of the present invention is characterized in that, comprises the following steps:

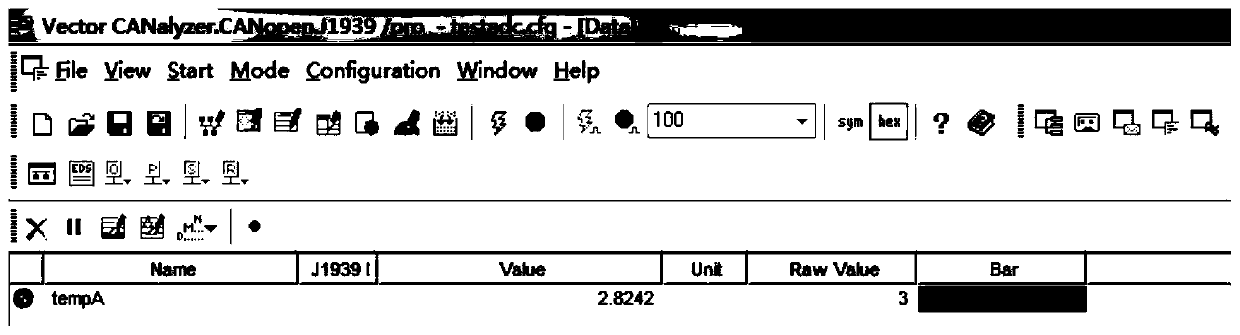

[0056] Step 1. Data acquisition: Use the CAN bus to receive the original output data of the voltage measured by the ADC module, and record the corresponding output value data and the voltage data at both ends of the potentiometer when the 10 sets of potentiometers are at the same value;

[0057] Step 2, curve fitting: use the curve fitting tool Curve Fitting provided by Matlab to fit the measured data, and obtain the coefficients a, b, and c of the ADC transfer function;

[0058] Step 3. Parameter storage: the computer sends it to the DSP through the CAN bus, and the DSP stores the parameters in the EEPROM after receiving the parameters;

[0059] Step 4. According to the ADC transfer function coefficient stored in the EEPROM, the result measured by the PT1000 temperature sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com