Ceramic-metal composite assembly sealing strength measuring device and using method thereof

A metal composite, strength measurement technology, applied in the direction of measuring device, strength characteristics, using stable tension/pressure to test the strength of materials, etc., can solve the problem of small size of ceramic-metal composite components, unable to meet user index requirements, unable to guarantee products Delivery quality and other issues, to achieve the effect of convenient measurement, improved delivery reliability, and easy delivery standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, in conjunction with the accompanying drawings and preferred embodiments, the ceramic-metal composite component seal strength measuring device and its use method proposed in the present invention are as follows: Its specific implementation, structure, feature and effect thereof are described in detail as follows. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures or characteristics of one or more embodiments may be combined in any suitable manner.

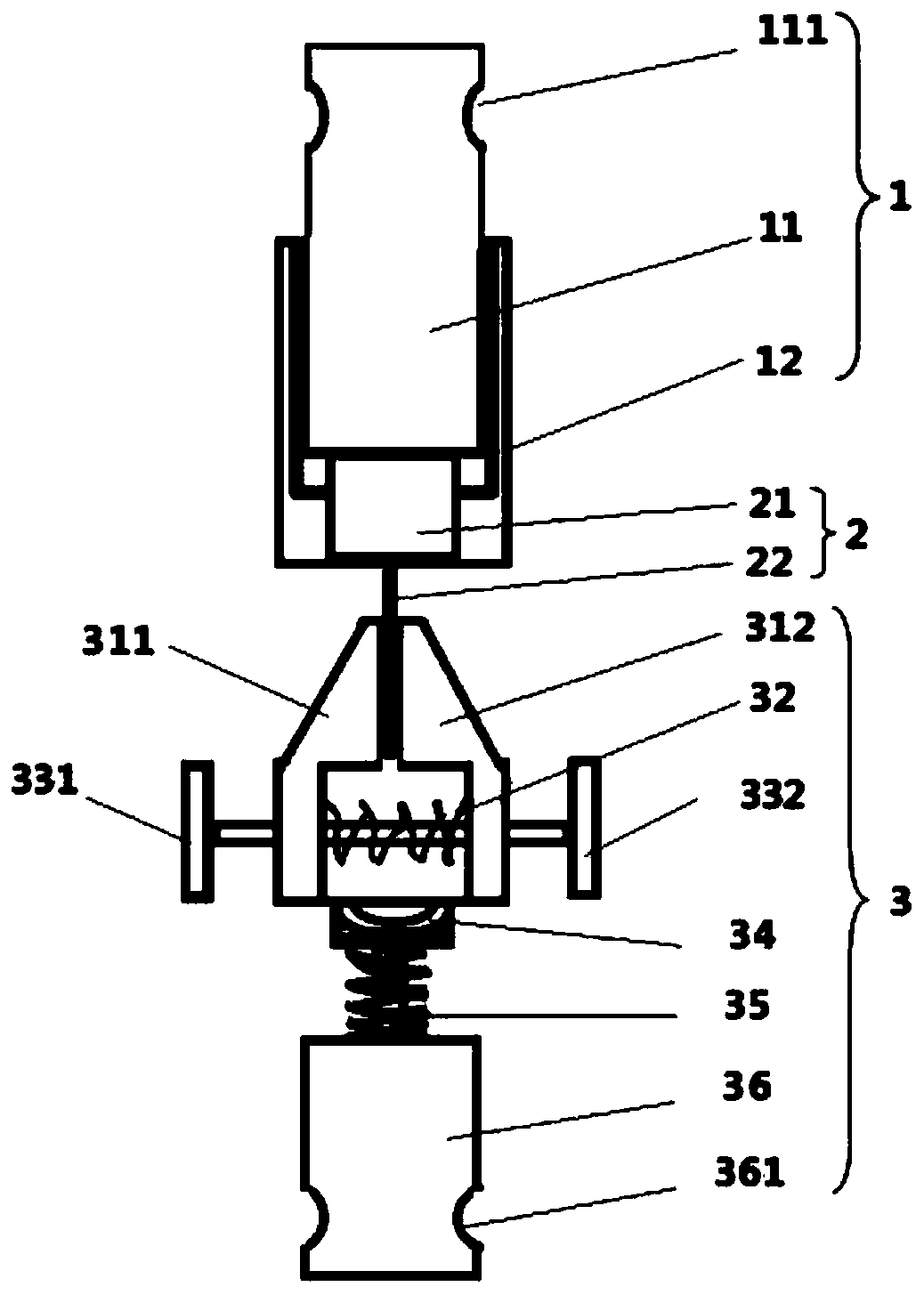

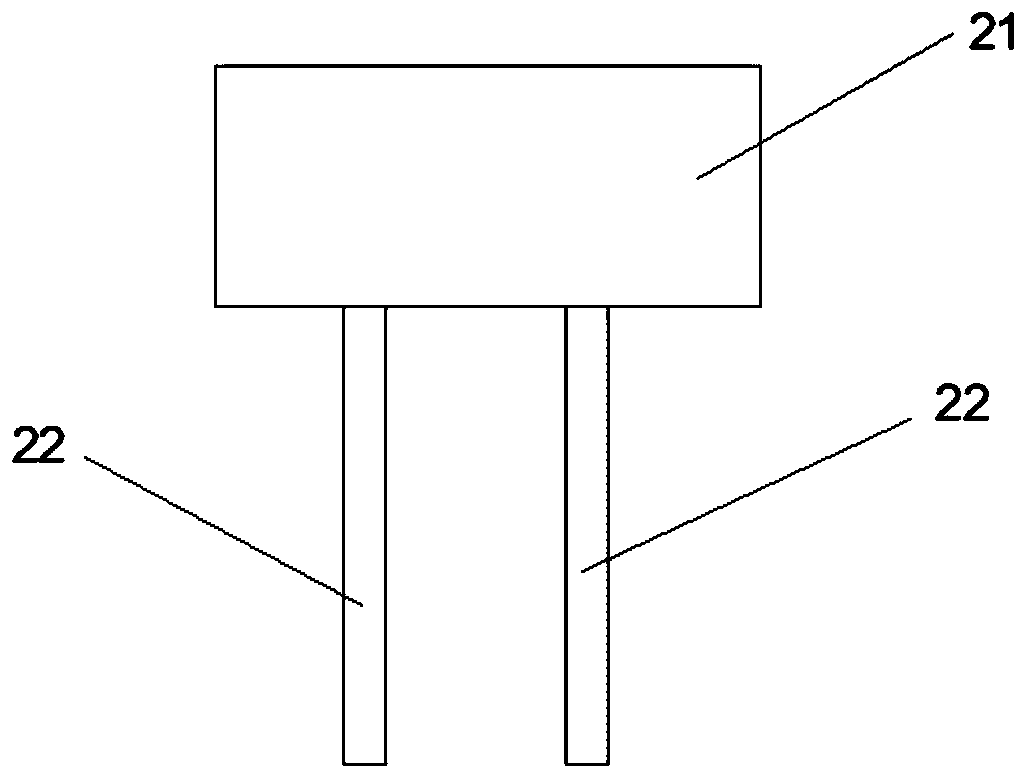

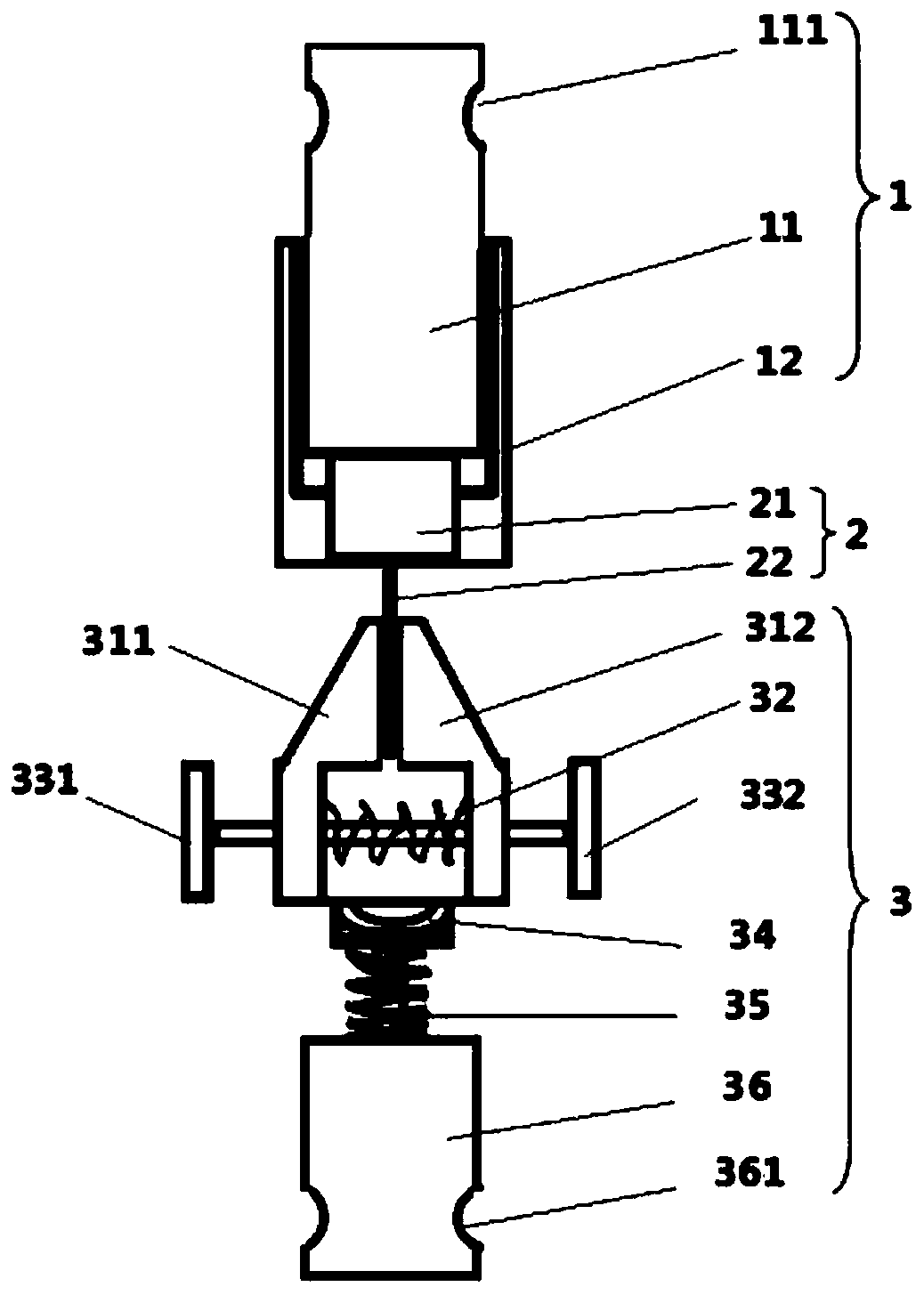

[0041] Such as figure 1 As shown, an embodiment of the present invention proposes a device for measuring the sealing strength of a ceramic-metal composite assembly, which includes a positioning device 1 and a stretching device 3; wherein,

[0042] The positioning device 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com