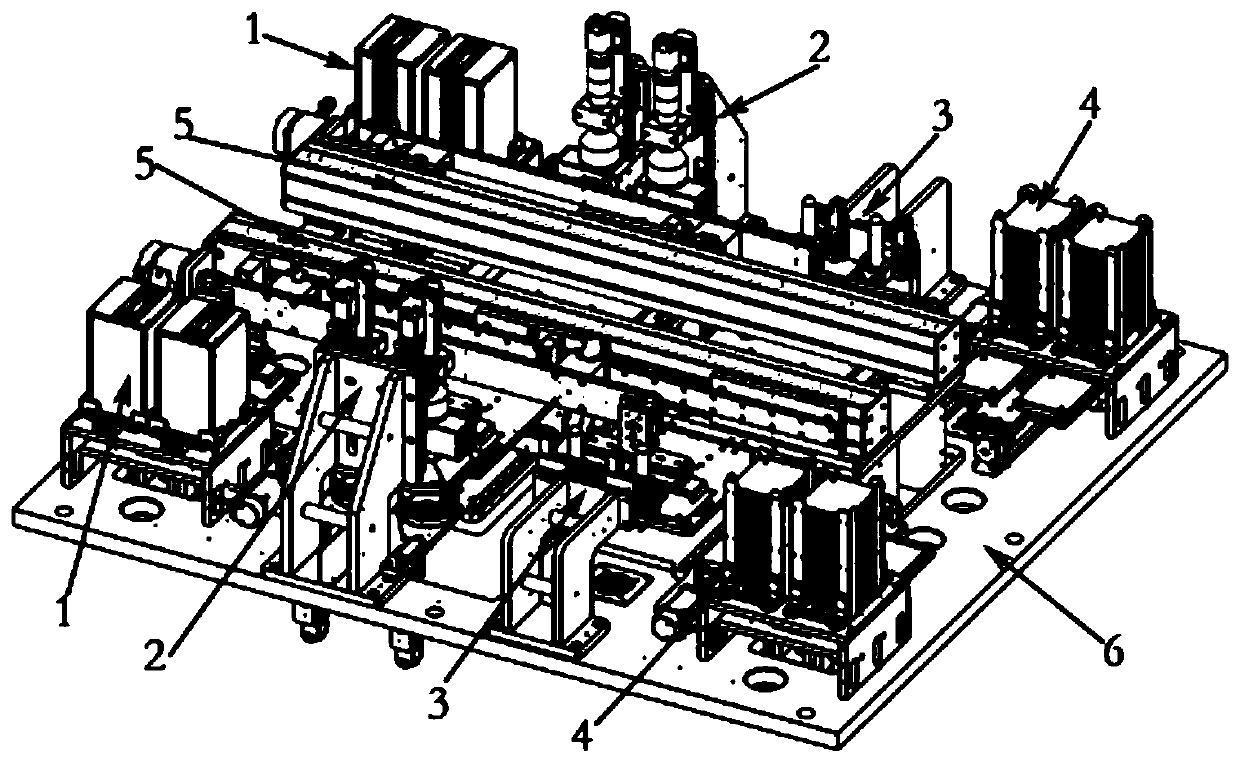

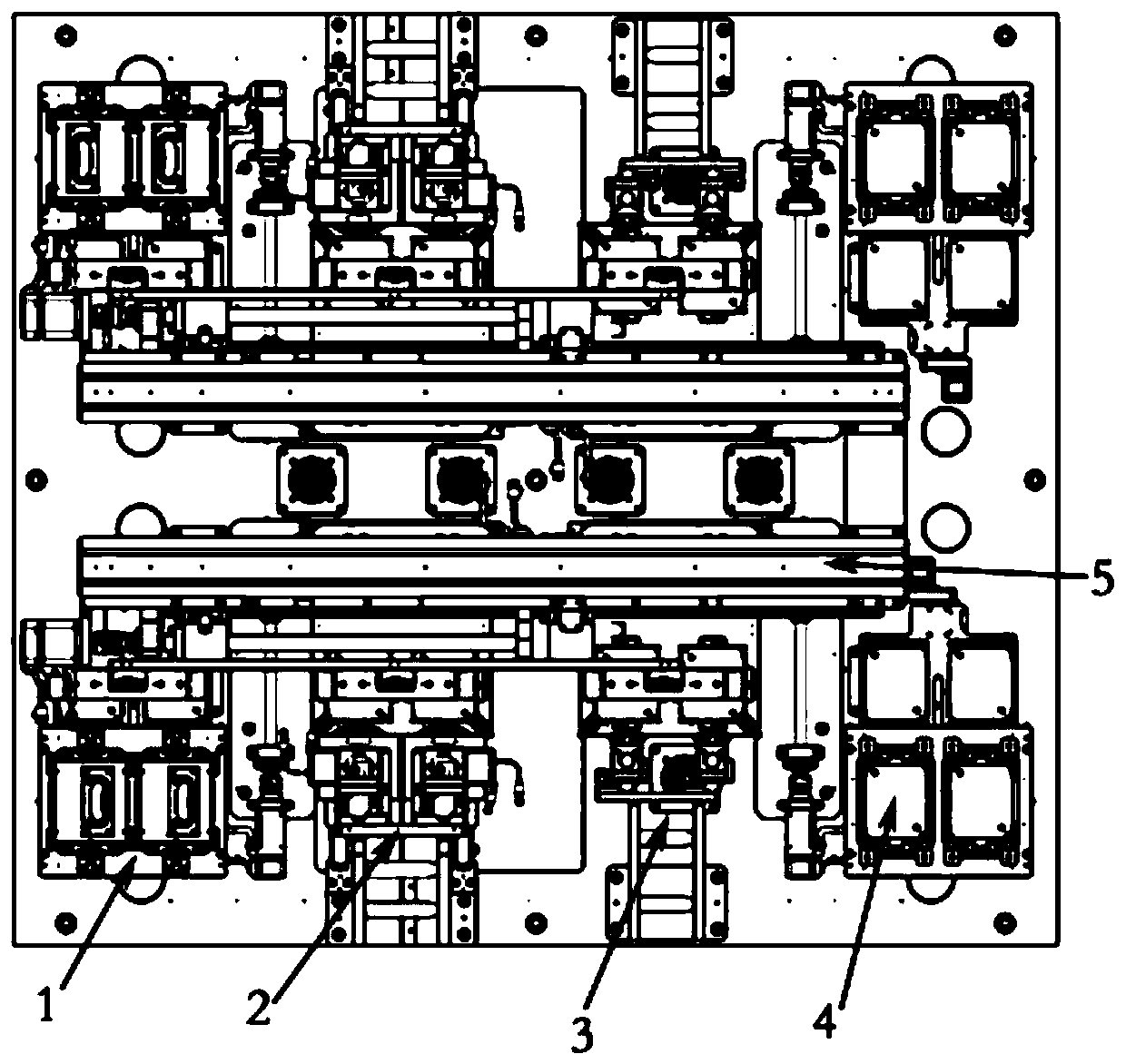

Defect detection equipment

A defect detection and equipment technology, applied in the optical field, can solve the problems affecting the detection efficiency and detection effect of machine equipment, manual detection and detection effect and detection efficiency can not meet the demand, etc., and achieve the effect of preventing pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

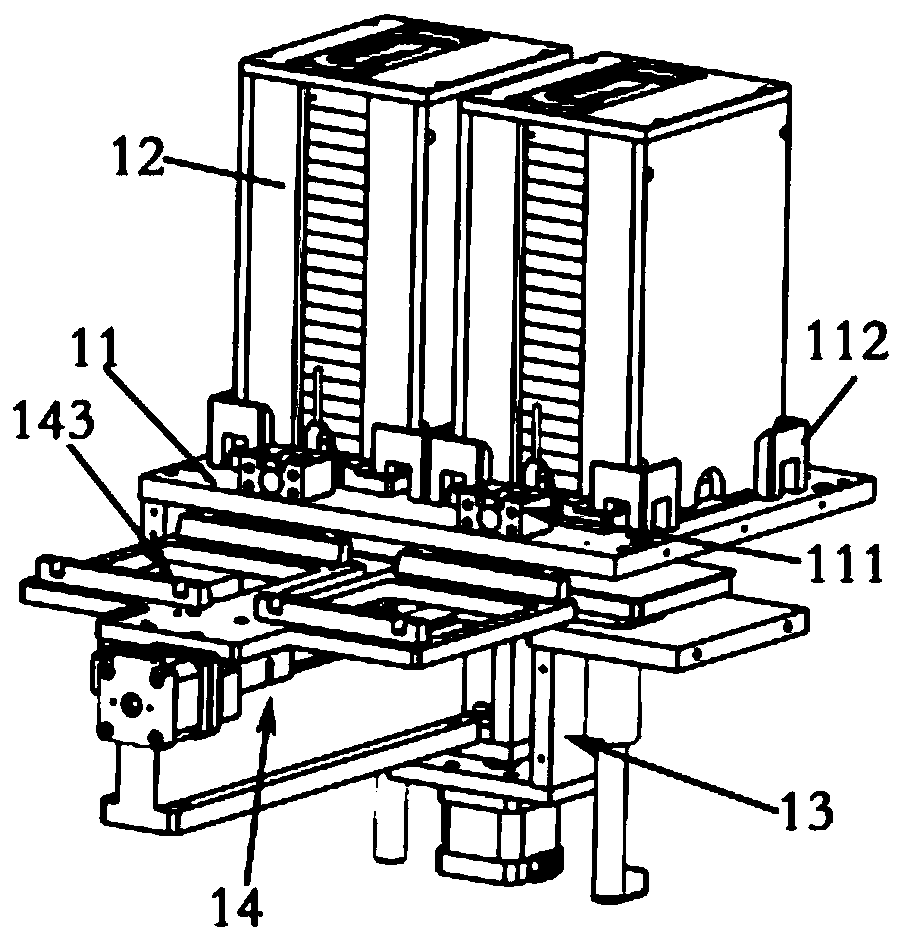

[0076] like Figure 10 As shown, according to an embodiment of the present invention, the detection module 2 of the present invention includes a mobile platform 21 , a light source assembly 22 and an imaging system 23 . In this embodiment, the light source assembly 22 is located above the mobile platform 21 , and the imaging system 23 is located above the light source assembly 22 . The mobile platform 21 is adjustable in the X and Y directions, and the light source assembly 22 and the imaging system 23 are adjustable in the Z direction.

[0077] like Figure 11As shown, according to an embodiment of the present invention, the mobile platform 21 includes a tray carrying platform 211 , an X-direction driving member 212 and a Y-direction driving member connected to the tray carrying platform 211 . In this embodiment, both the X-direction driver 212 and the Y-direction driver 213 are arranged on one side of the tray carrying platform 211 in an offset manner, which is conducive t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com