Thermal error compensation calculation method, device and equipment of machine tool, and storage medium

A calculation method and technology of thermal error, applied in computer control, program control, instruments, etc., can solve problems such as inaccurate prediction and inaccurate model establishment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

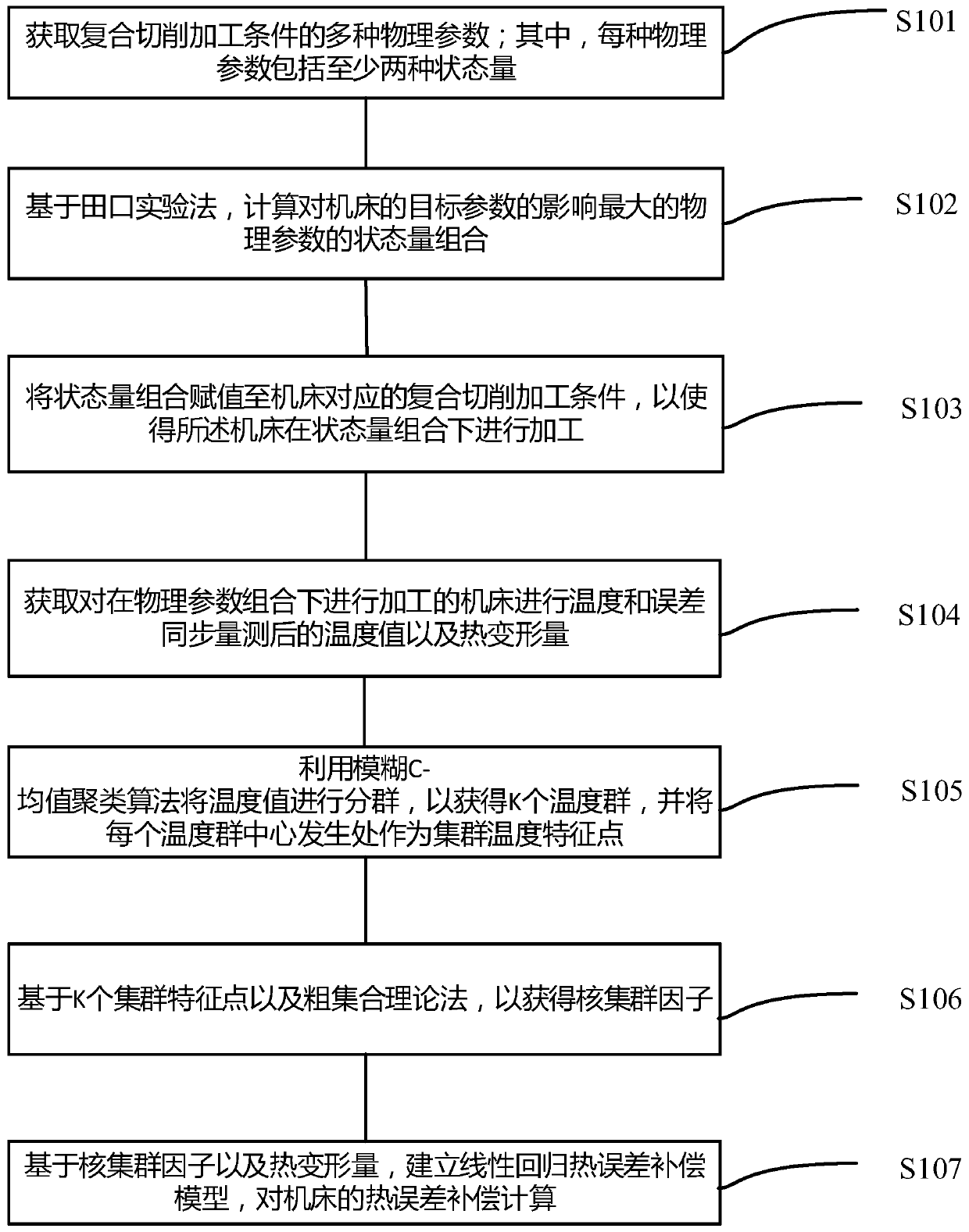

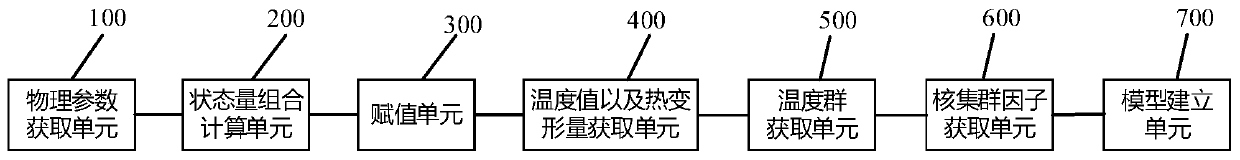

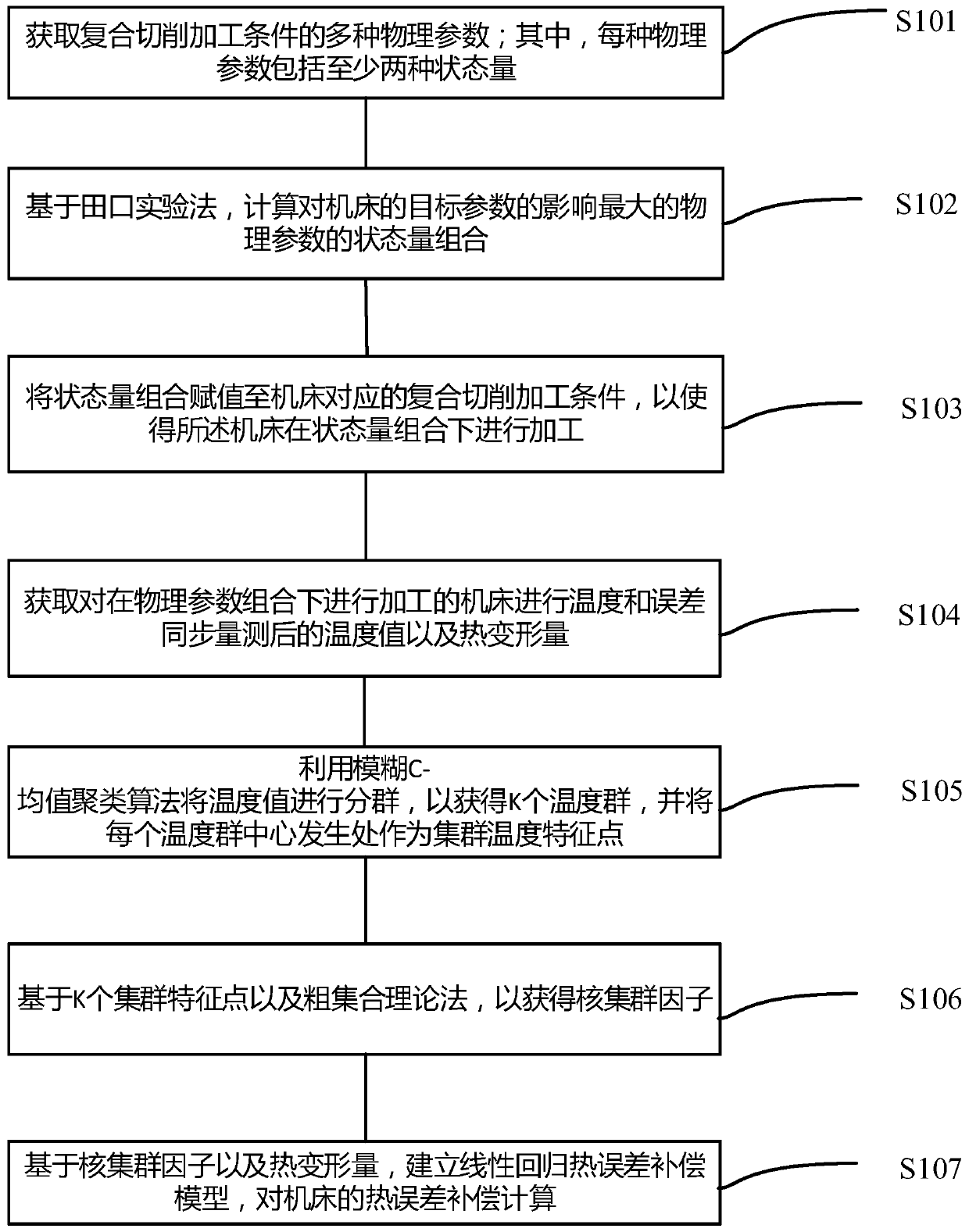

[0057] see figure 1 , the first embodiment of the present invention provides a thermal error compensation calculation method of a machine tool, which can be executed by the thermal error compensation calculation device of the machine tool, in particular, by one or more processors in the thermal error compensation calculation device of the machine tool to perform, and include at least the following steps:

[0058] S101. Obtain multiple physical parameters of compound cutting processing conditions; wherein each physical parameter includes at least two state quantities.

[0059] In this embodiment, the physical parameters include at least eight types, and each physical parameter includes at least two state quantities. Specifically, the physical parameters and physical states include: the processing state includes periodic processing and non-periodic processing state, etc.; Physical parameters of processing methods include face milling, end milling, and drilling; physical paramet...

no. 3 example

[0107] The third embodiment of the present invention also provides a thermal error compensation computing device for a machine tool, including a processor, a memory, and a computer program stored in the memory, and the computer program can be executed by the processor to achieve the above-mentioned The thermal error compensation calculation method of the machine tool described in the embodiment.

no. 4 example

[0109] A fourth embodiment of the present invention provides a computer-readable storage medium, the computer-readable storage medium includes a stored computer program, wherein, when the computer program is running, the device where the computer-readable storage medium is located is controlled to execute the following steps: The thermal error compensation calculation method of the above-mentioned machine tool.

[0110] Exemplarily, the computer program may be divided into one or more units, and the one or more units are stored in the memory and executed by the processor to implement the present invention. The one or more units may be a series of computer program instruction segments capable of performing specific functions, and the instruction segments are used to describe the execution process of the computer program in the thermal error compensation computing device of the machine tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com