Prediction function control method for chemical process genetic algorithm optimization

A technology for predictive function control and chemical process, applied in program control, comprehensive factory control, electrical program control, etc., can solve problems such as model mismatch and shorten running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0140] Taking the injection molding stage and pressure holding stage in the injection molding process as an example, the injection molding process is a typical multi-stage chemical process, and the adjustment method is to control the valve opening of the proportional valve and the control of the pressure holding pressure.

[0141] The present invention is achieved through the following technical solutions:

[0142] A new type of predictive function control method optimized for chemical process genetic algorithm, including the following steps:

[0143] Step 1. For different stages in the chemical process, establish a switching system model based on the state space model of the controlled object, specifically:

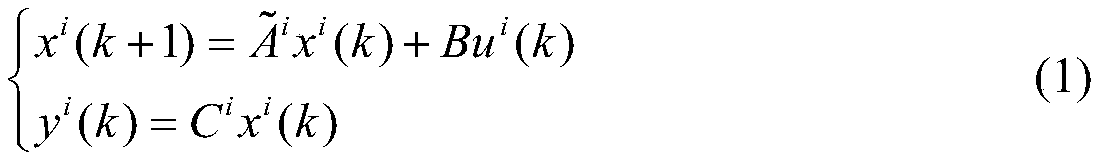

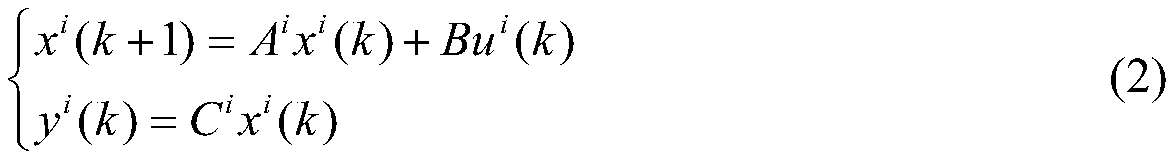

[0144] 1.1 Construct a new multi-stage chemical process with disturbance system model:

[0145]

[0146] Among them, k represents the current time, x i (k)∈R n , u i (k)∈R 1 ,y i (k)∈R 1 Respectively represent the state, output and input of the batch process at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com