A 2D Model Predictive Control Method Based on Genetic Algorithm Optimization for Batch Processes

A technology of model predictive control and genetic algorithm, which is applied in the direction of genetic rules, genetic models, adaptive control, etc., can solve problems such as limitations and multi-stage intermittent processes, achieve good tracking, solve the impact of control performance, and achieve better control effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

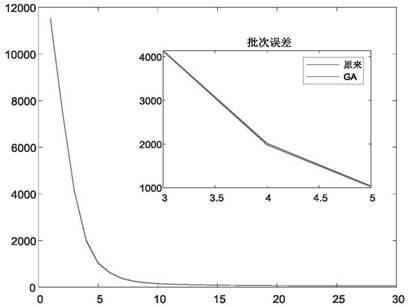

Image

Examples

Embodiment 1

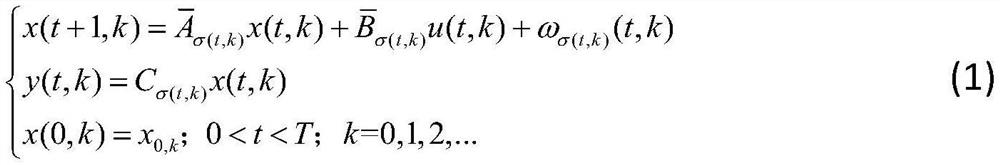

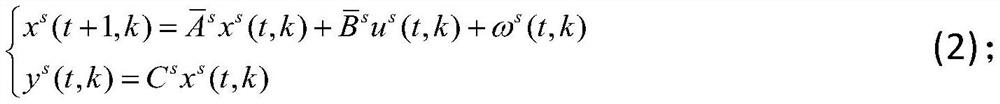

[0232] In this embodiment, citing the conversion of the injection molding process from the injection section to the pressure holding section as an example, the injection section is defined as the first stage, and the pressure holding section is defined as the second stage.

[0233] After definition, in the injection section, the model of the injection velocity (IV) corresponding to the valve opening (VO) can be described as:

[0234]

[0235] And the nozzle pressure (NP) model corresponding to the injection velocity is:

[0236]

[0237] make u 1 (t,k)=VO(t,k),y 1 (t,k)=IV(t,k).

[0238] The response dynamics of the injection rate to the proportional valve has been described as a step mode, which translates into a state-space model as:

[0239]

[0240] Among them, δ(t,k) is a random variable between [0,1], and formula (36) is the state space model of the filling stage.

[0241] Similarly, in the pressure-holding section, the nozzle pressure model corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com