Upper vehicle body structure optimization method based on MDO technology

A car body structure and optimization method technology, which is applied in the field of automotive CAE simulation, can solve problems such as excess body performance and heavy body, achieve the effects of solving high time-consuming problems, realizing light weight of the car body, and improving product design quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

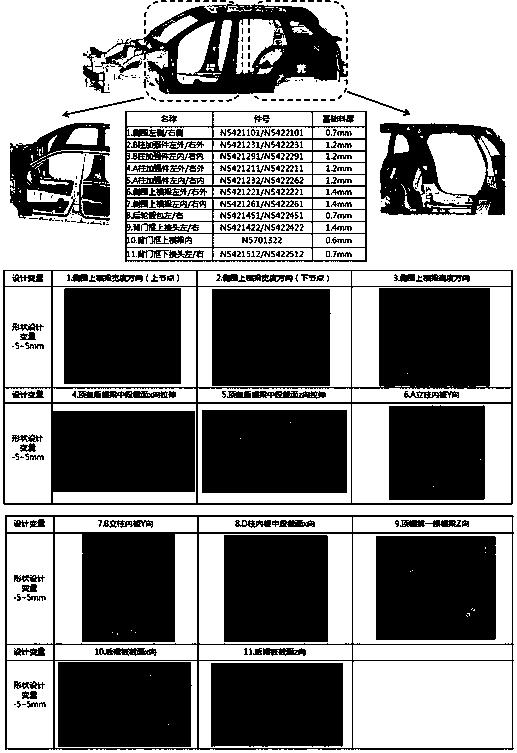

[0024] The present invention will be further described below by taking a certain SUV model as an example.

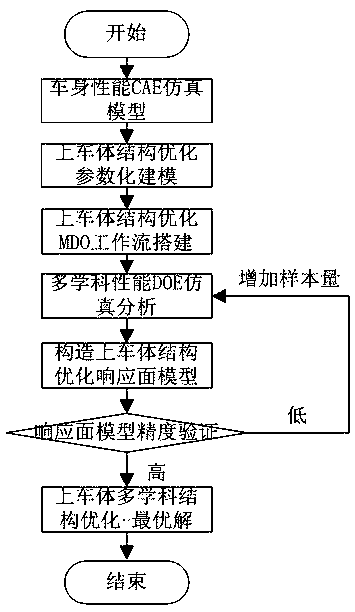

[0025] Such as figure 1 A method for optimizing the upper body structure based on MDO technology is shown, including the following steps:

[0026] Step 1: Establish a finite element model of the car body to realize the multi-disciplinary performance simulation analysis of the car body. The multi-disciplinary performance of the car body includes body stiffness, body mode, body torsional fatigue and body mounting point stiffness;

[0027] Specifically, based on an SUV model, the Hypermesh pre-processing software is used to establish a finite element model of the body;

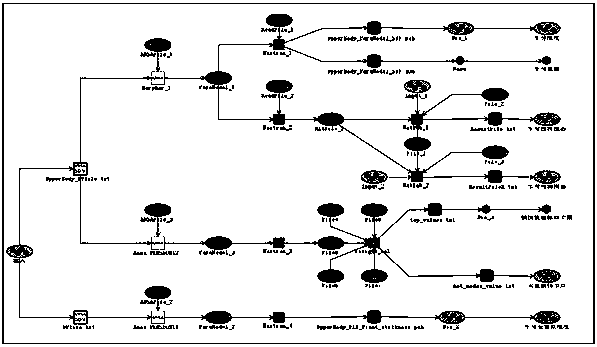

[0028] Based on the body stiffness analysis conditions, establish the corresponding SPC and MPC constraints, and apply the corresponding load excitation, set the displacement response measurement points of the body structure and output the response value through the .pch file, and realize the CAE simulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com