A kind of silicon carbon negative electrode and preparation method thereof

A silicon carbon and negative electrode technology, applied in electrode manufacturing, battery electrodes, electrode current collector coating, etc., can solve the problems affecting the first coulomb efficiency and high current charge and discharge capacity of lithium ion batteries, the large volume expansion rate of silicon carbon negative electrode, Large volume effect and other problems, to achieve the effect of large-scale industrial application, simple manufacturing process, and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Based on the same inventive concept, an embodiment of the present invention also provides a method for preparing a silicon carbon negative electrode, comprising the following steps:

[0057] (1) coating the active material layer slurry on the current collector 1;

[0058] (2) coating the functional coating slurry on the active material layer 2 of the current collector 1 to obtain a silicon carbon negative electrode;

[0059] The functional coating slurry is prepared by the following method:

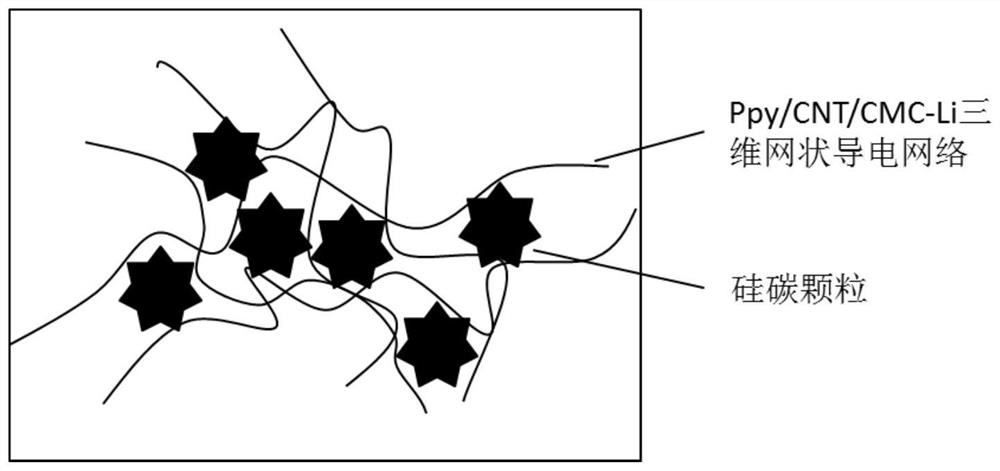

[0060] A functional coating slurry is prepared by dispersing pyrrole monomers in a solution containing SWCNTs; during the reaction process, pyrrole monomers are polymerized to form Ppy, and Ppy and SWCNTs form a three-dimensional network conductive network.

[0061] When the synthesis method and polymerization conditions of Ppy are different, the macroscopic properties and microscopic morphology of the obtained Ppy will be different, resulting in certain differences in the physica...

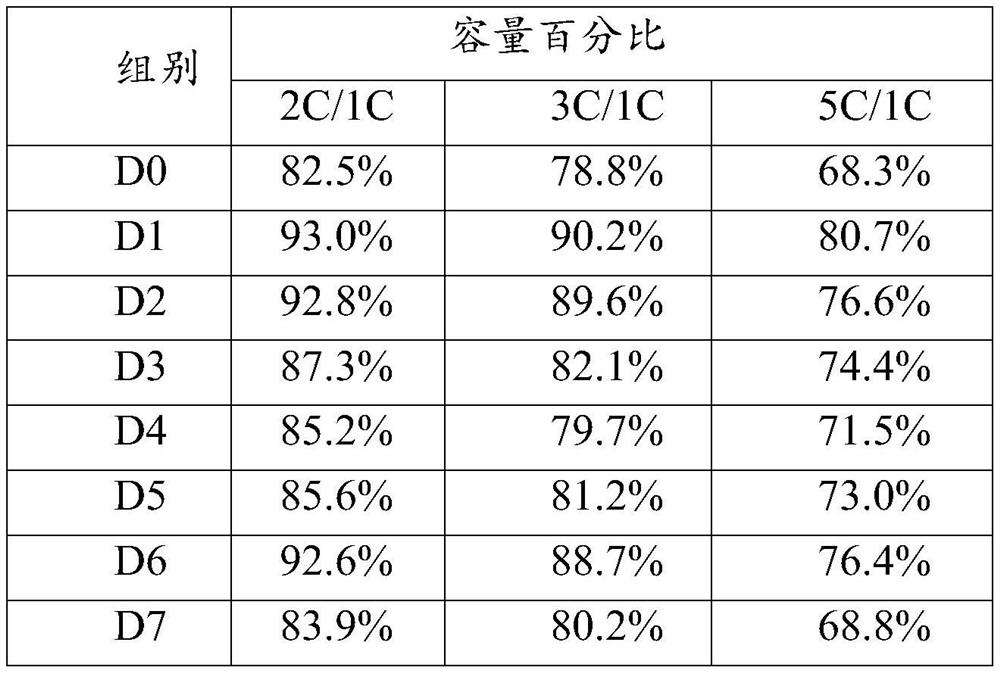

Embodiment 1

[0086] This embodiment provides a silicon-carbon negative electrode C1, which includes a current collector, an active material layer coated on the current collector, and a functional coating B1 coated on the active material layer; the current collector is copper foil, The active material layer includes a silicon-carbon negative electrode material, a conductive agent and a binder. The silicon-carbon negative electrode material includes SiO and graphite, and SiO accounts for 8% by mass of the silicon-carbon negative electrode material. The conductive agent is conductive carbon black (SP), and the bonding agent is The agent is a combination of sodium carboxymethylcellulose (CMC) and styrene-butadiene rubber (SBR), and the mass ratio of silicon carbon negative electrode material, conductive agent and binder is: 95.6:1:3.4; functional coating B1 includes Ppy, SWCNT and CMC-Li, the mass ratio of Ppy, SWCNT and CMC-Li is: 45:50:5, Ppy forms a three-dimensional mesh conductive network ...

Embodiment 2

[0093] This embodiment provides a silicon carbon negative electrode C2, the silicon carbon negative electrode C2 includes a current collector, an active material layer coated on the current collector and a functional coating B2 coated on the active material layer, the current collector and the active material layer Same as embodiment 1, functional coating B2 is different from functional coating B1 in embodiment 1, functional coating B2 comprises Ppy, SWCNT and CMC-Li, the mass ratio of Ppy, SWCNT and CMC-Li is: 45:50 :5, Ppy forms a three-dimensional mesh conductive network with SWCNT and CMC-Li. During the preparation of functional coating B2, the molar ratio of HTAB, oxalic acid, and pyrrole monomers is 1:0.8:1.6.

[0094] In this embodiment, the preparation method of silicon carbon negative electrode C2 comprises the following steps:

[0095] (1) Preparation of silicon carbon negative electrode C0

[0096] The preparation method of silicon carbon negative electrode C0 is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com