Material multi-stage multi-direction sorting control method and computer program product thereof

A technology for controlling computers and control methods, applied to program control, sorting, and program control in sequence/logic controllers, which can solve problems such as long installation periods, high debugging costs, and high difficulty coefficients, and reduce testing costs , improve efficiency, improve the effect of shunting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

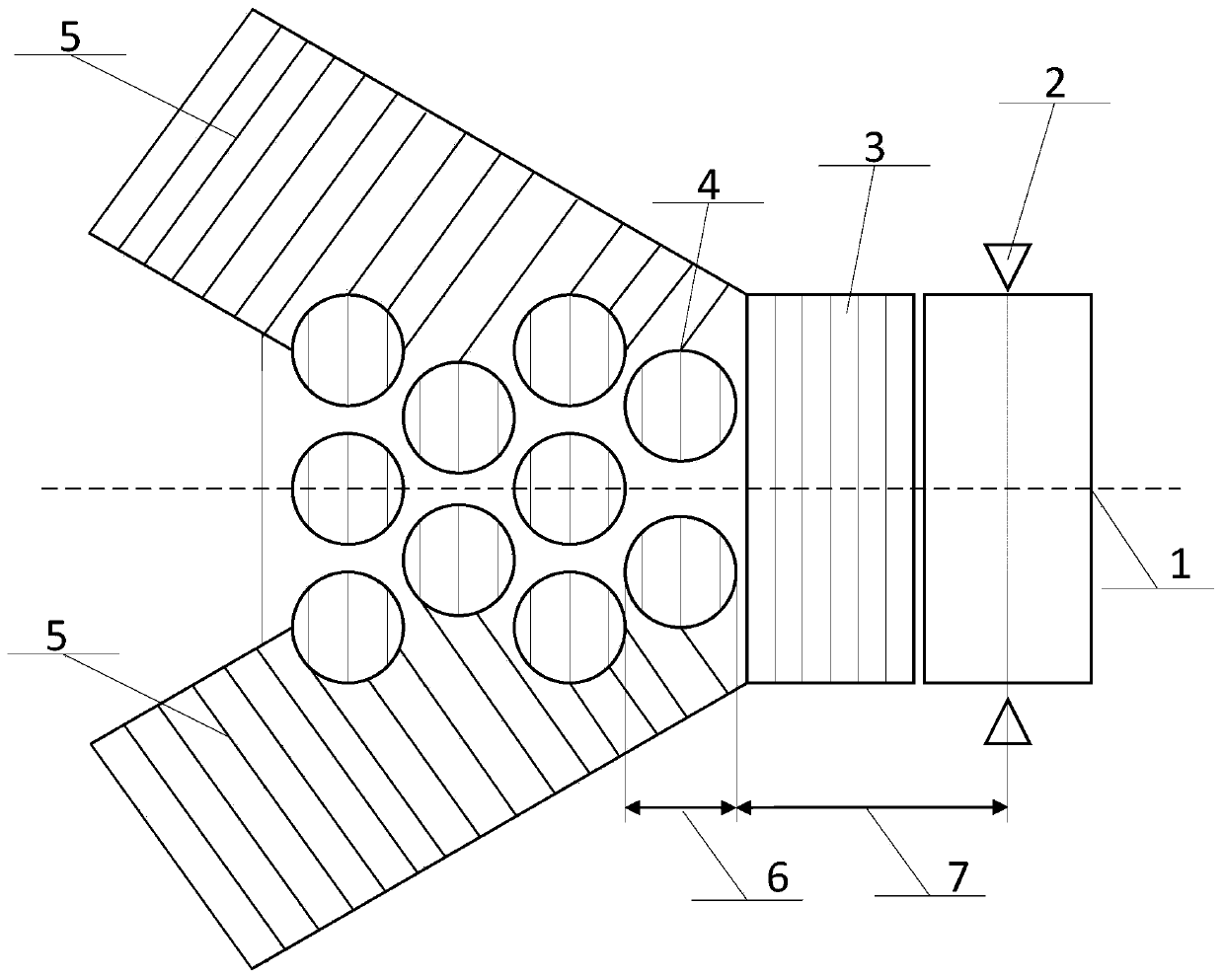

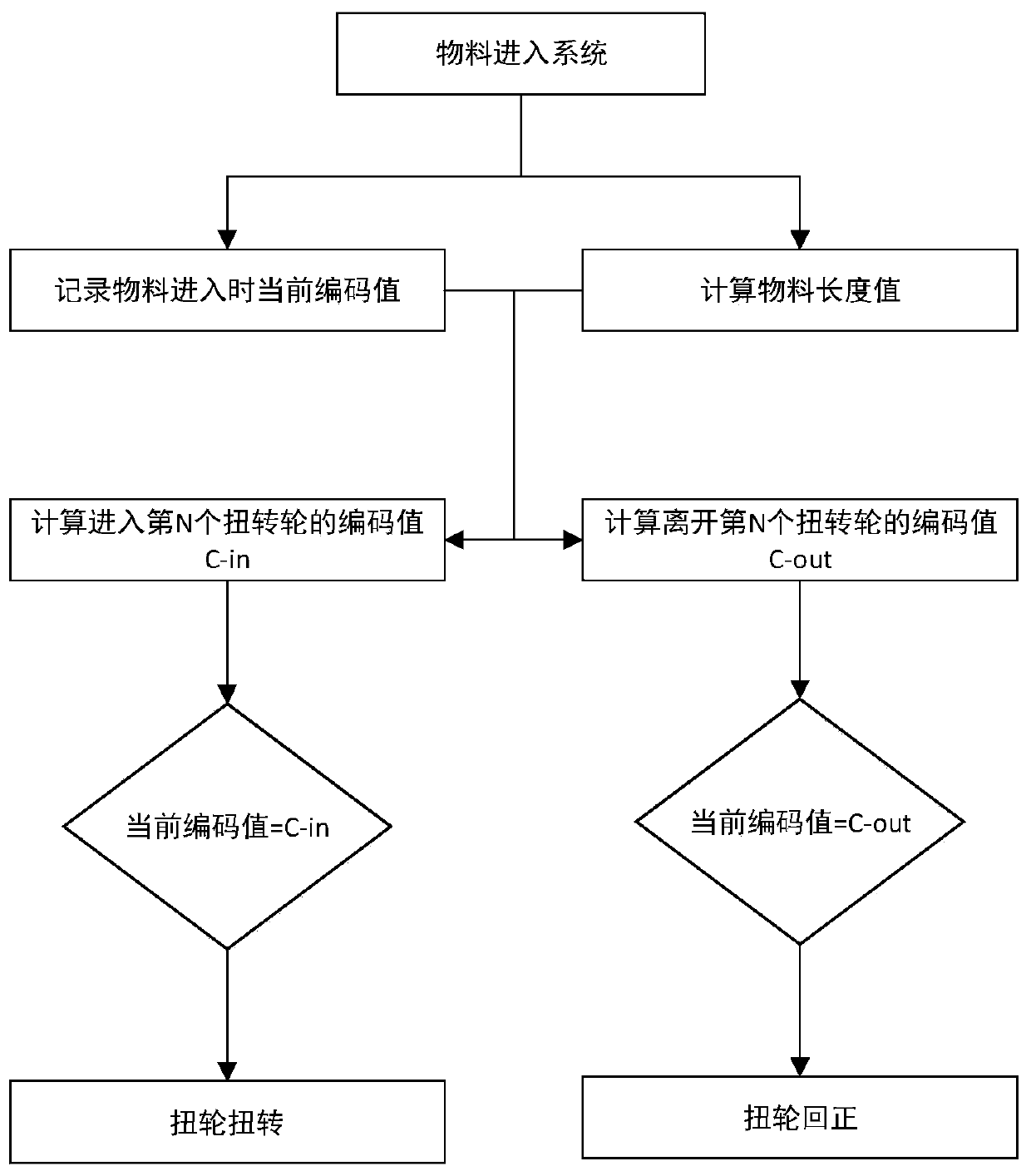

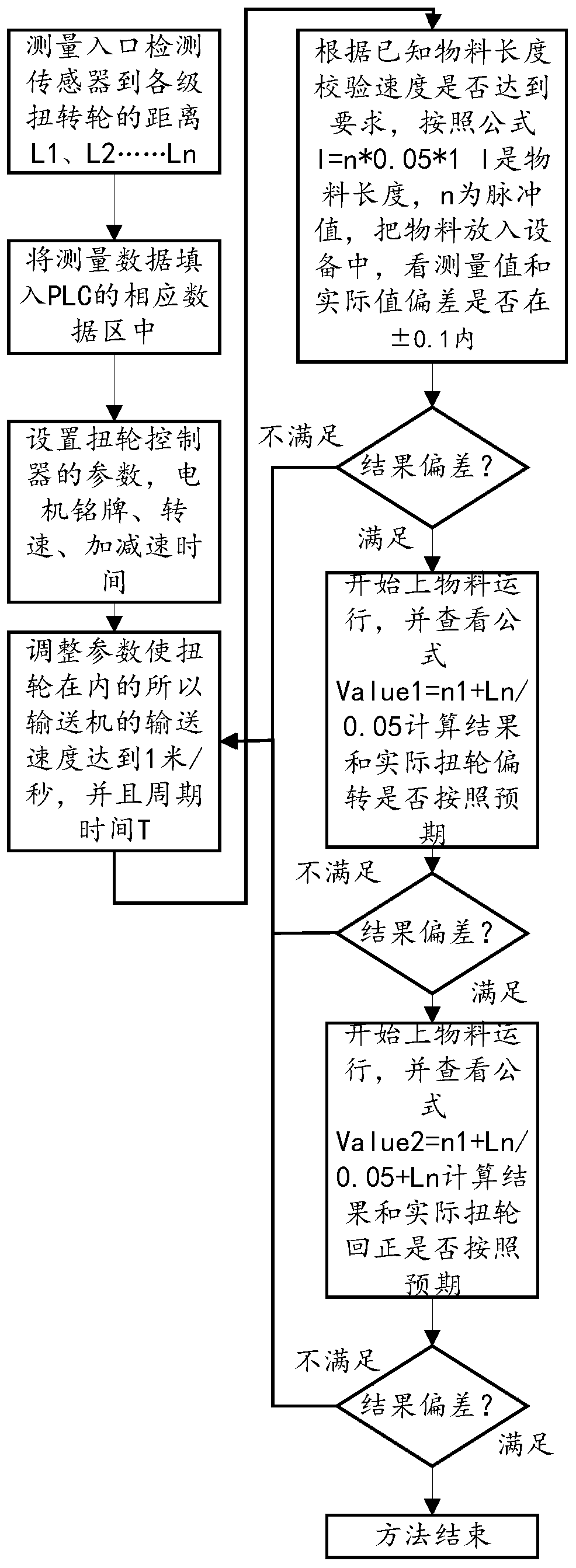

[0075] The schematic diagram of an embodiment of the working process of a multi-level and multi-directional sorting control method for materials in the present invention can be found in figure 1 and figure 2 , to describe in detail the implementation process of the control method mainly includes the following two steps:

[0076] Step 1: Virtual star wheel encoder built with software

[0077] The virtual star wheel encoder is a method of using software to replace the function of the hardware encoder. First, we need to use the program to construct an oscillation frequency of a time period T, and then collect the frequency of the time oscillation. The frequency is the analog encoder. Pulse, the more pulses in the same time, the higher the oscillation frequency. This method is to use periodic sampling to simulate the pulse value generated by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com