Wedging type stamping part capable of achieving automatic positioning

An automatic positioning and stamping technology, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve the problems of manual placement and fixation of stamping parts, inability to fix stamping parts, waste of manpower and time, etc., to improve the use of Longevity, improved accuracy, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

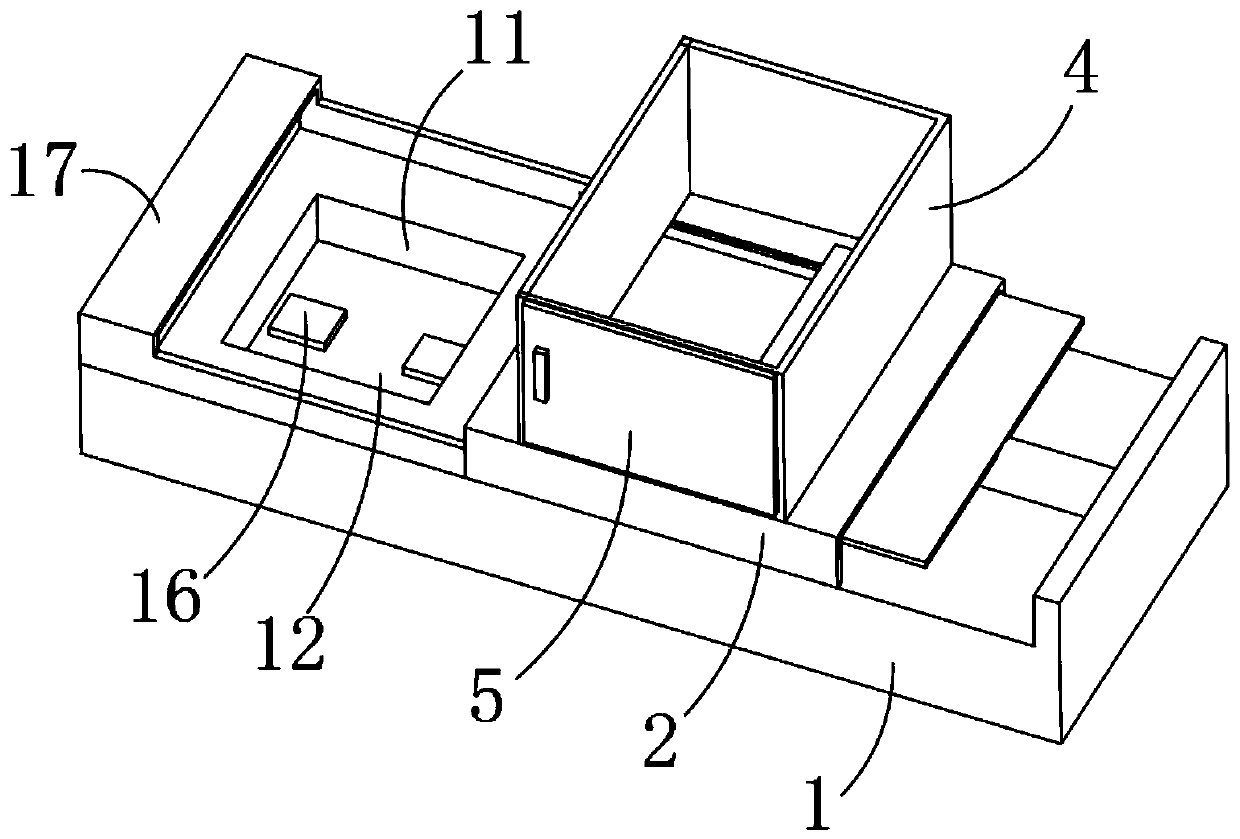

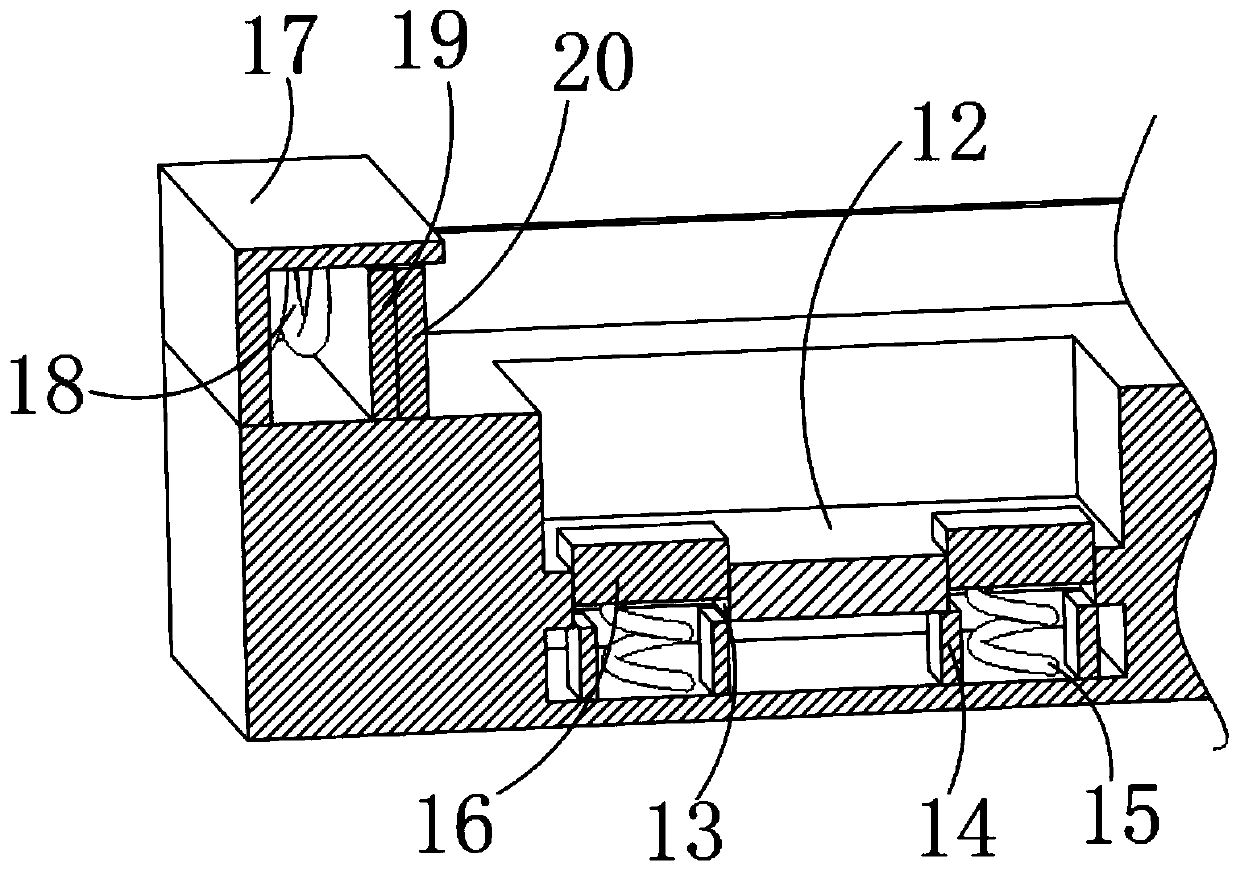

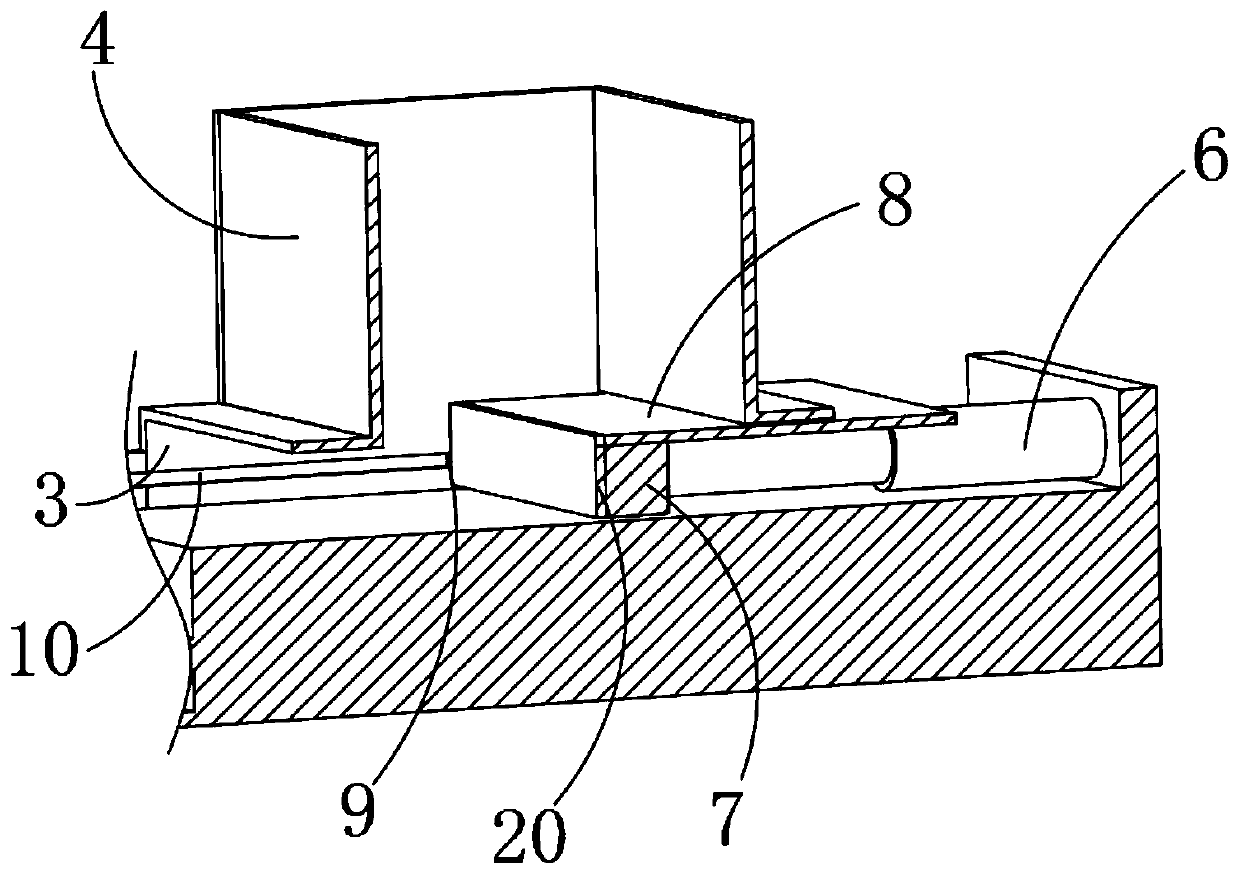

[0023] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a fitting stamping part that can be automatically positioned, a support seat 2 is installed in the middle of the top of the base 1, a through groove 3 is opened inside the support seat 2, and the top of the support seat 2 is installed There is a discharge box 4, a discharge door 5 is installed at one end of the discharge box 4, an electro-hydraulic rod 6 is installed at one end of the top of the base 1, and an extrusion block 7 is connected to one end of the electro-hydraulic rod 6, and the extrusion block 7 The top of the baffle 8 is connected with a baffle 8, the top of the baffle 8 fits the bottom of the discharge box 4, and the extrusion block 7 pushes the stamping parts forward, the baffle 8 ensures that the inside of the discharge box 4 The stamping plate will not fall downwards, the input end of the electro-hydraulic rod 6 is electrically connected to the output end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com