Automatic manipulator discharging machine for powder spraying line

A technology for manipulators and manipulator components, which is applied to conveyor objects, transportation and packaging, etc., can solve problems such as physical harm to operators, affect production line output, increase product damage rate, etc., to improve production efficiency, improve brand awareness, and increase quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

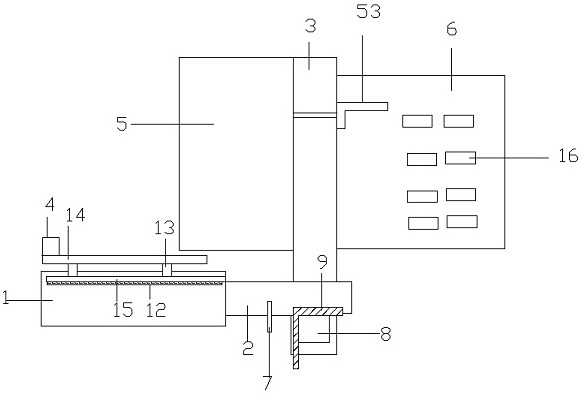

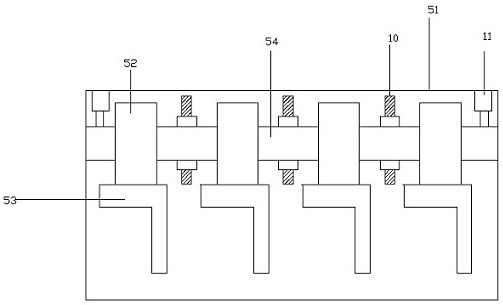

[0023] Such as Figure 1-2 As shown, the powder spraying line automatic manipulator discharger of this embodiment includes a PLC controller 4 and a first transmission frame 1 and a second transmission frame 2 arranged in sequence; one side of the first transmission frame 1 is provided with a limit Position plate 12; Described limit plate 12 is fixed on the support frame 14 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com