A Horizontal Multi-Cutter CNC Lathe Based on Precision Machining

A CNC lathe, multi-tool technology, applied in metal processing equipment, metal processing mechanical parts, tool holders, etc., can solve the problems of easy positioning error, reduced processing quality, reduced processing efficiency, etc., to ensure processing quality, guarantee The effect of processing quality and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

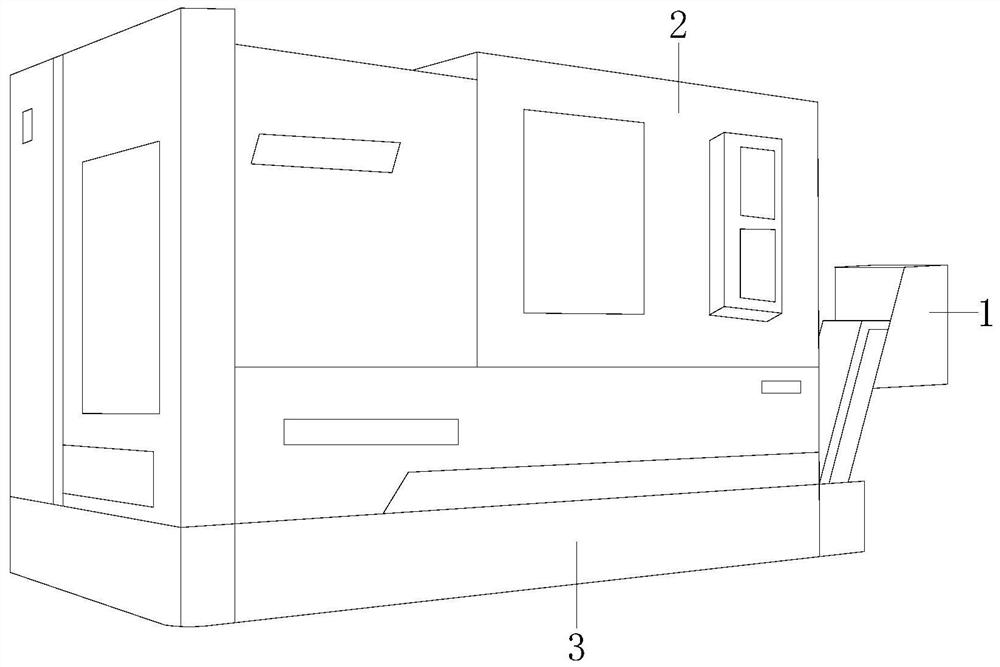

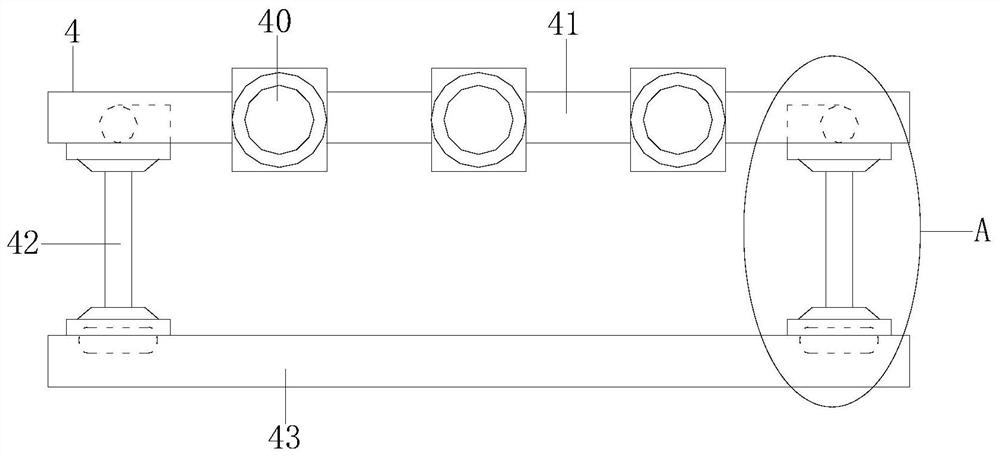

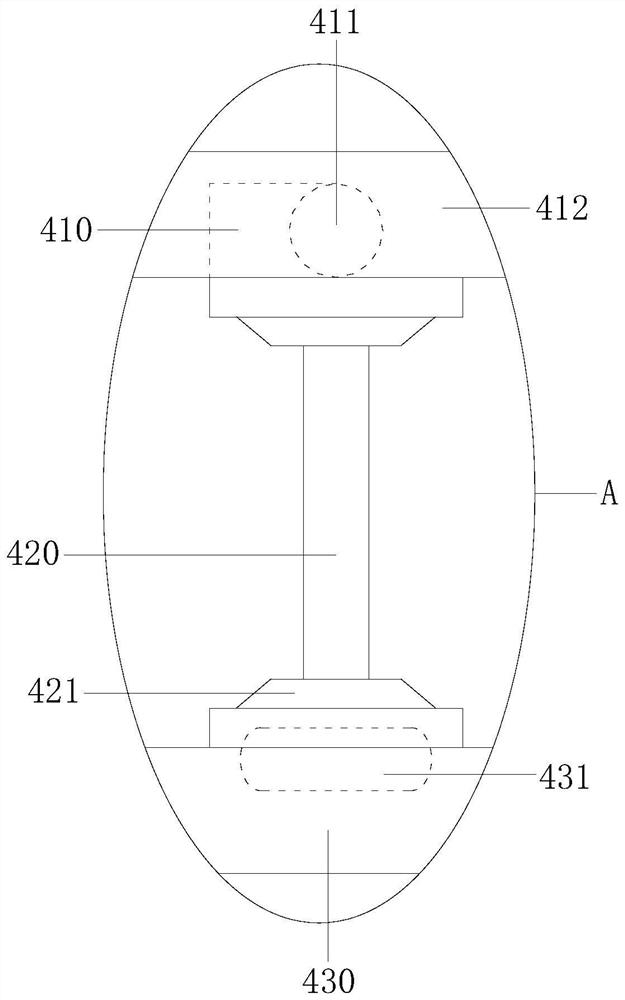

[0025] Example 1 see Figure 1-5 , the present invention provides a technical solution for a horizontal multi-tool CNC lathe based on precision machining: its structure includes a control machine 1, a CNC machine 2, a base 3, and a multi-tool device 4, and the control machine 1 is installed on the CNC machine 2 and the two are electrically connected, the CNC machine 2 is locked with the base 3, the multi-knife device 4 is installed on the control machine 1, and the multi-knife device 4 consists of a cutter head 40, an upper frame structure 41, a center column structure 42, a Composed of frame structure 43, the cutter head 40 performs micro-distance mobile finishing during operation, which not only ensures the processing quality but also ensures the processing efficiency. The cutter head 40 is installed on the upper frame structure 41, and the center column structure 42 and The upper frame structure 41 and the lower frame structure 43 are installed and connected. When the equip...

Embodiment 2

[0027] Example 2 see Figure 6 , the present invention provides a technical solution for a horizontal multi-tool CNC lathe based on precision machining: the tool frame structure 401 is equipped with a control ring 4010, and the control ring 4010 is used to further improve the precision of the operation of the tool head 40. and stability, the knife frame structure 401 and the splicing axis circle 402 are provided with a scale bar 4011, the control ring 4010 is equipped with an ellipse 500 and a scanner 502, and the control ring 4010 is glued to a brake layer 501, The ellipse 500 realizes local strengthening and precise movement, the friction performance of the brake layer 501 improves the fitting degree of movement, and the scanner 502 realizes constant scanning to ensure precise processing and timely control.

[0028]The control ring 4010 is used to further improve the accuracy and stability of the operation of the cutter head 40. The elliptical wheel 500 realizes local enhanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com