High-precision welding positioner

A welding positioner, high-precision technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of single function and low positioning accuracy, and achieve improved safety performance, compact structure, and protection of workpieces and personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

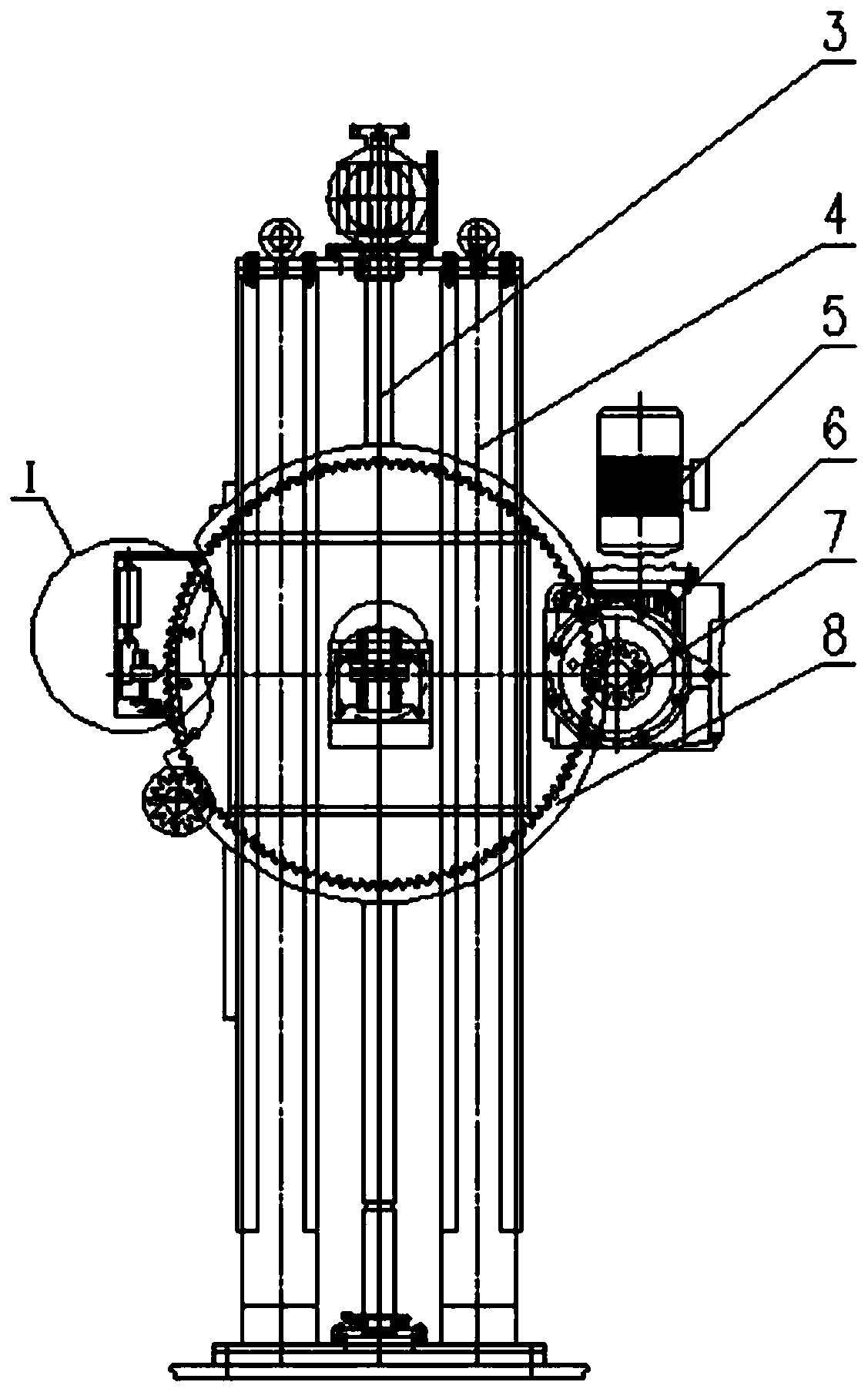

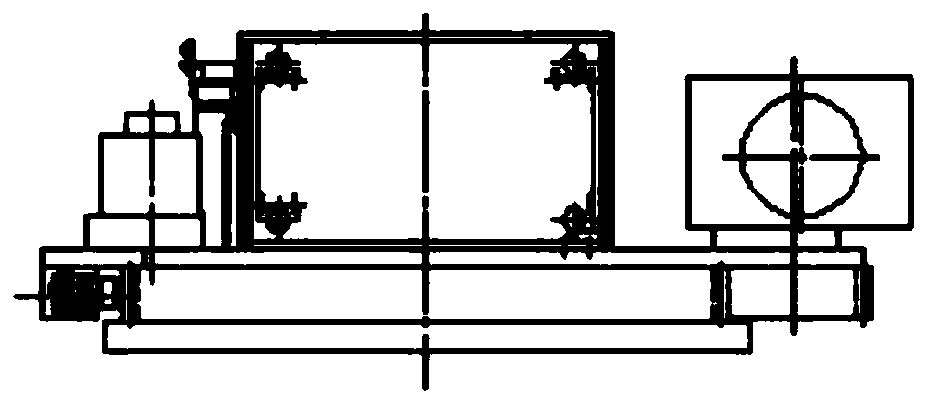

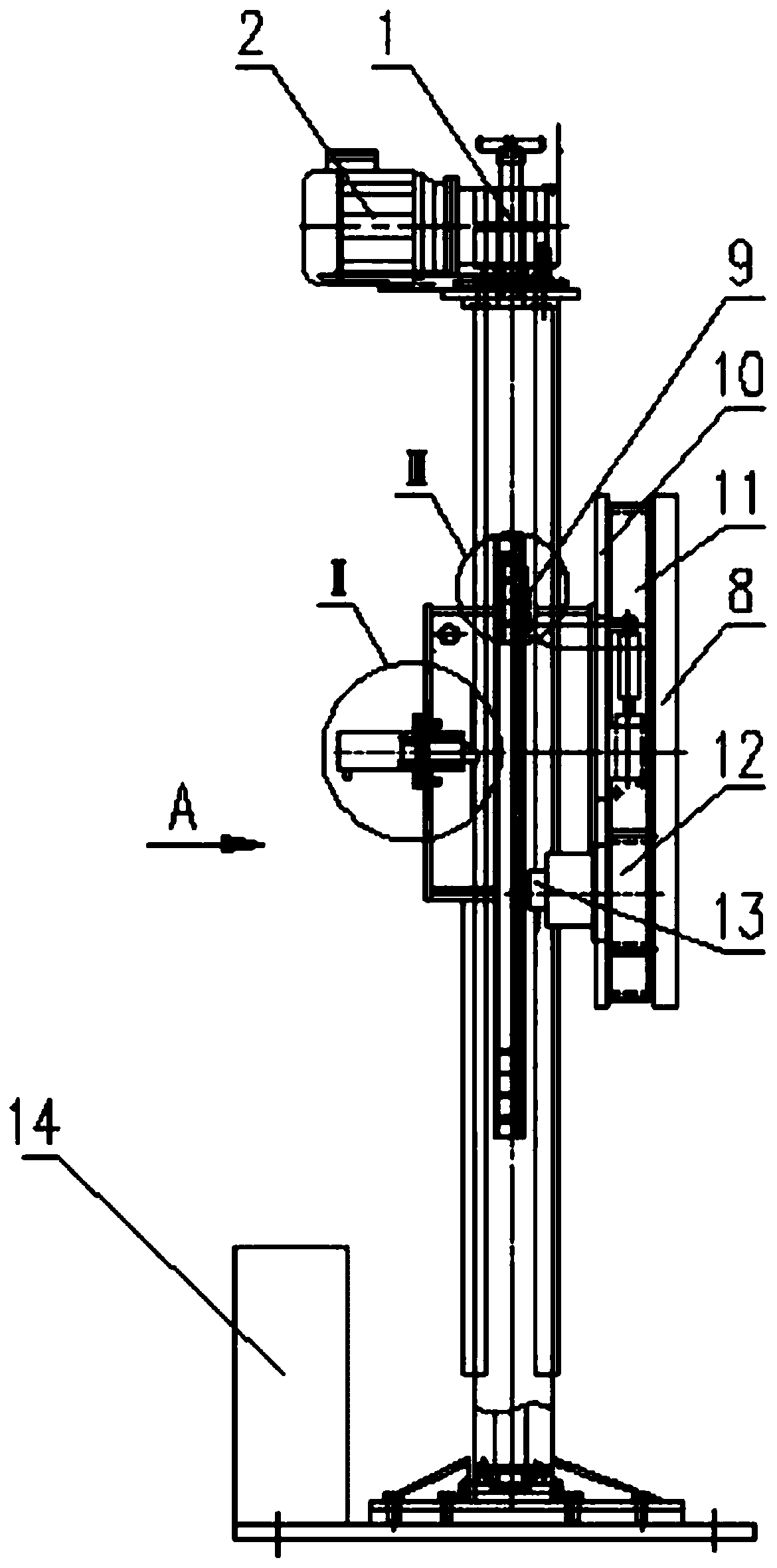

[0038] see Figure 1 to Figure 7 , a high-precision welding positioner, including a lifting component, a column 4, a lifting gear box 10, a rotary table 8, a grating ruler 9, a rotary support 11, a rotary drive component, an anti-rotation device, an anti-falling device and an electric control system 14. The lifting gear box 10 is set on the column 4, and the lifting assembly is used to drive the lifting gear box 10 to move up and down along the column 4; the rotary table 8 is connected to the lifting gear box 10 through the slewing support 11; the external belt of the slewing support 11 There is a ring gear; the rotary drive assembly is installed on the lifting gear box 10 to drive the rotary table 8 to rotate; the grating ruler 9 is installed on the side of the column 4, and the electric control system 14 is connected with various electrical components.

[0039] The lifting assembly includes a lifting reducer 1, a lifting motor 2 and a screw rod 3; the lifting reducer 1 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com