Sleeper truss stirrup molding device

A truss and stirrup technology, applied in the field of sleeper truss stirrup-insertion devices, can solve the problems of low work efficiency, high labor intensity, heavy weight, etc., and achieve the effects of strong versatility, convenience, and high consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention and the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

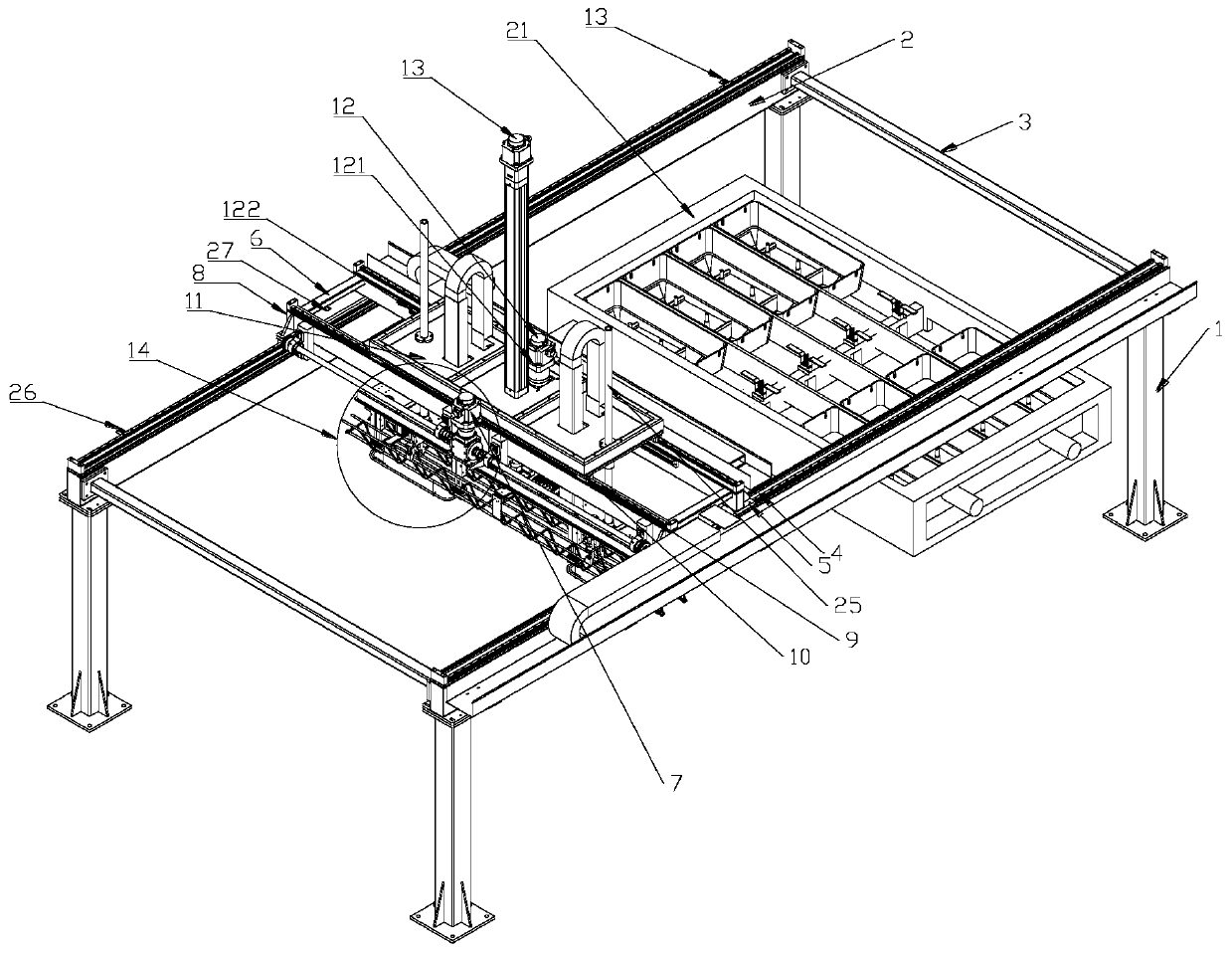

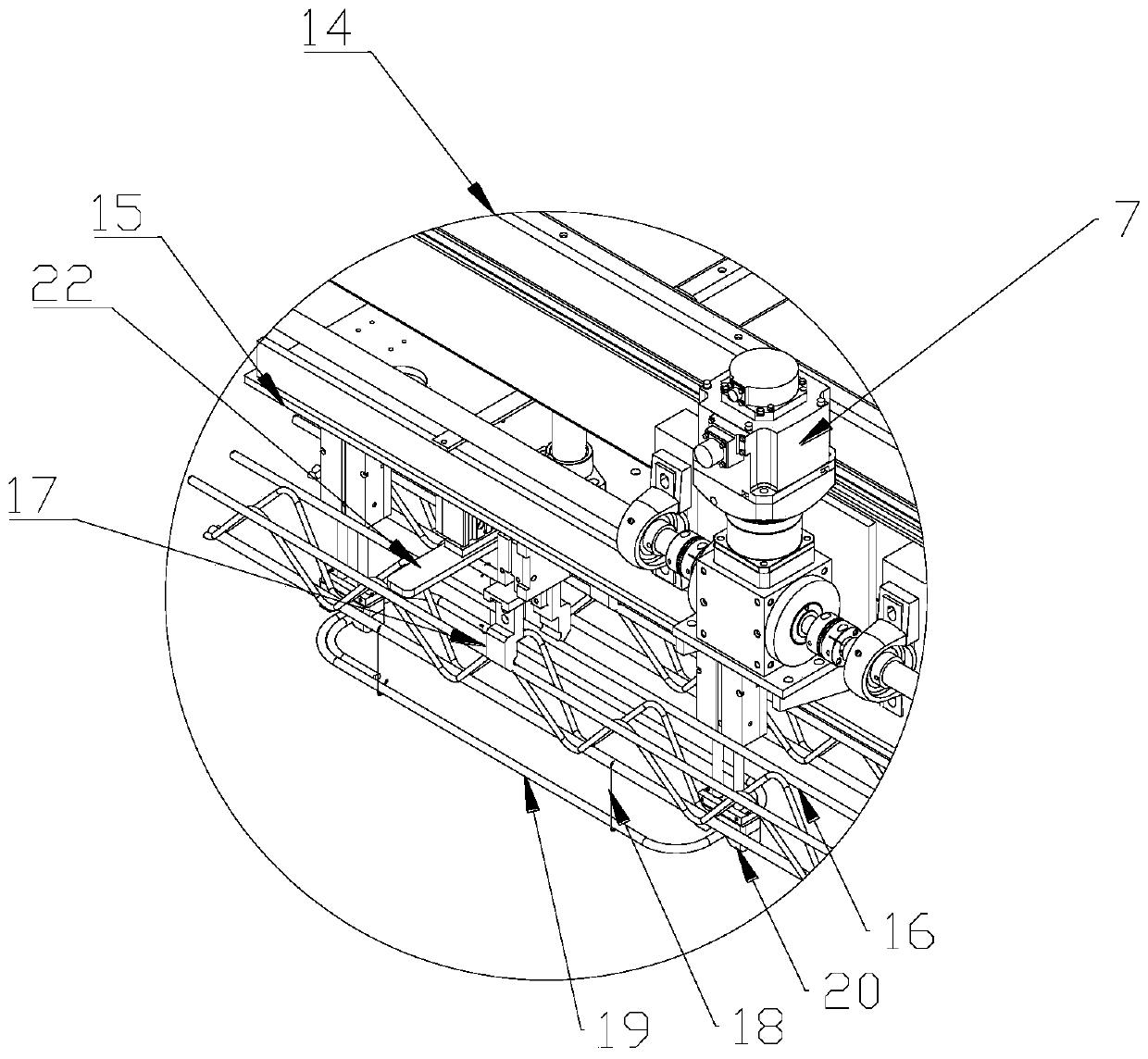

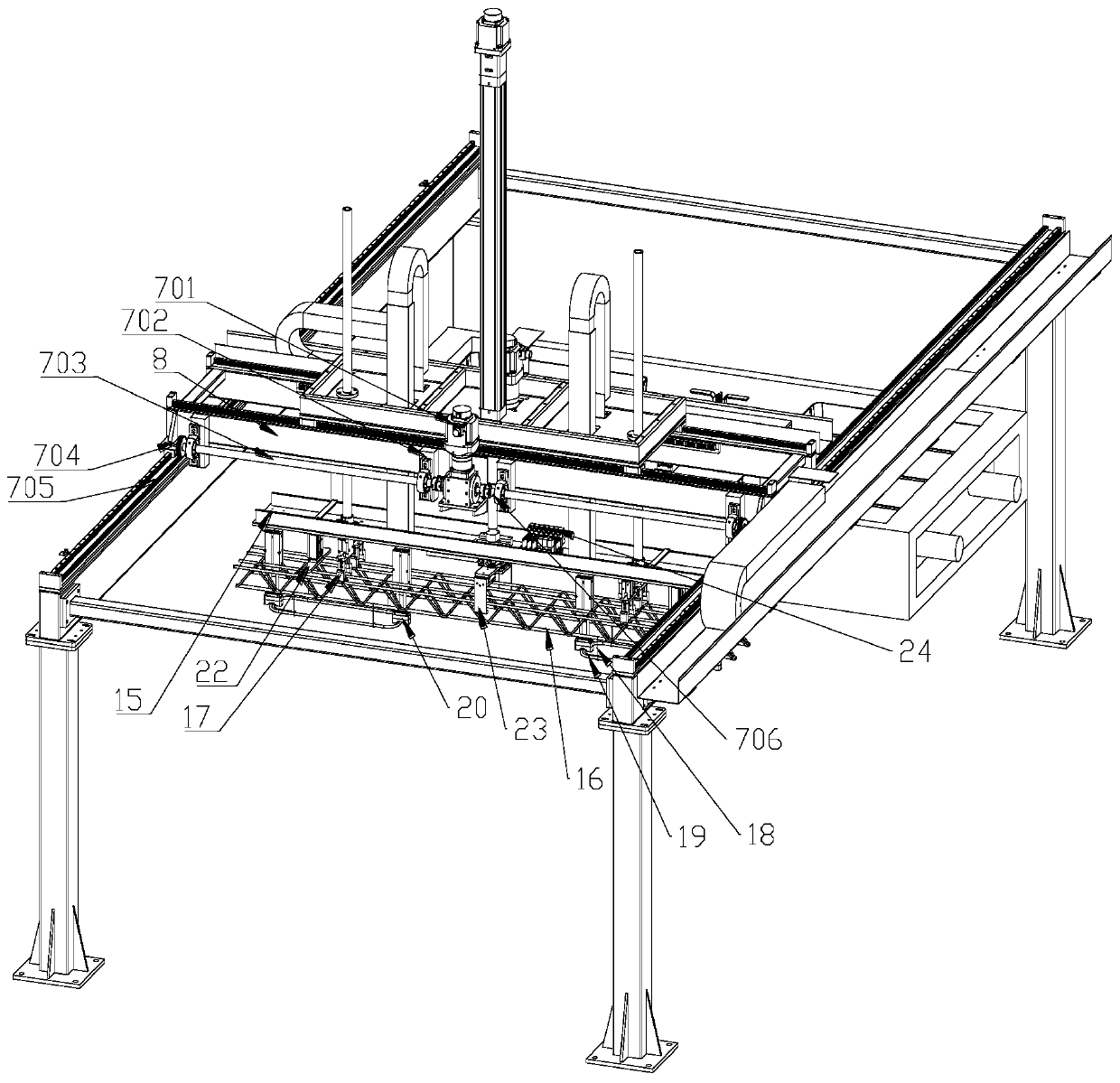

[0026] figure 1 It is an overall structure axonometric drawing of the present invention; figure 2 yes figure 1 Partial enlarged view in ; image 3 yes figure 1 Axonometric drawing of the overall structure from another angle; Figure 4 yes figure 1 side view. combine figure 1 , 2 , 3, 4, the present invention is described as follows:

[0027] As shown in the figure, a sleeper truss stirrup molding device of the present invention includes a frame-type bracket, the bracket includes uprights 1, and support beams 2 and connecting beams 3 are connected between the uprights 1, and the two frame-type brackets X-axis guide rails 4 are arranged on the side support beams 2 respectively, and X-axis guide rail grooves 5 that move axially along the X-axis guide rails 4 are installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com