Robot system for substation inspection

A robot system and inspection robot technology, which is applied in the field of mobile robots, can solve the problems of low efficiency, low accuracy, and slow response speed of manual inspections, shorten the abnormal response time, save personnel on-site inspection steps, shorten The effect of incident handling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the purpose, structure and functions of the present invention, a robot system for substation inspection of the present invention will be described in further detail below in conjunction with the accompanying drawings.

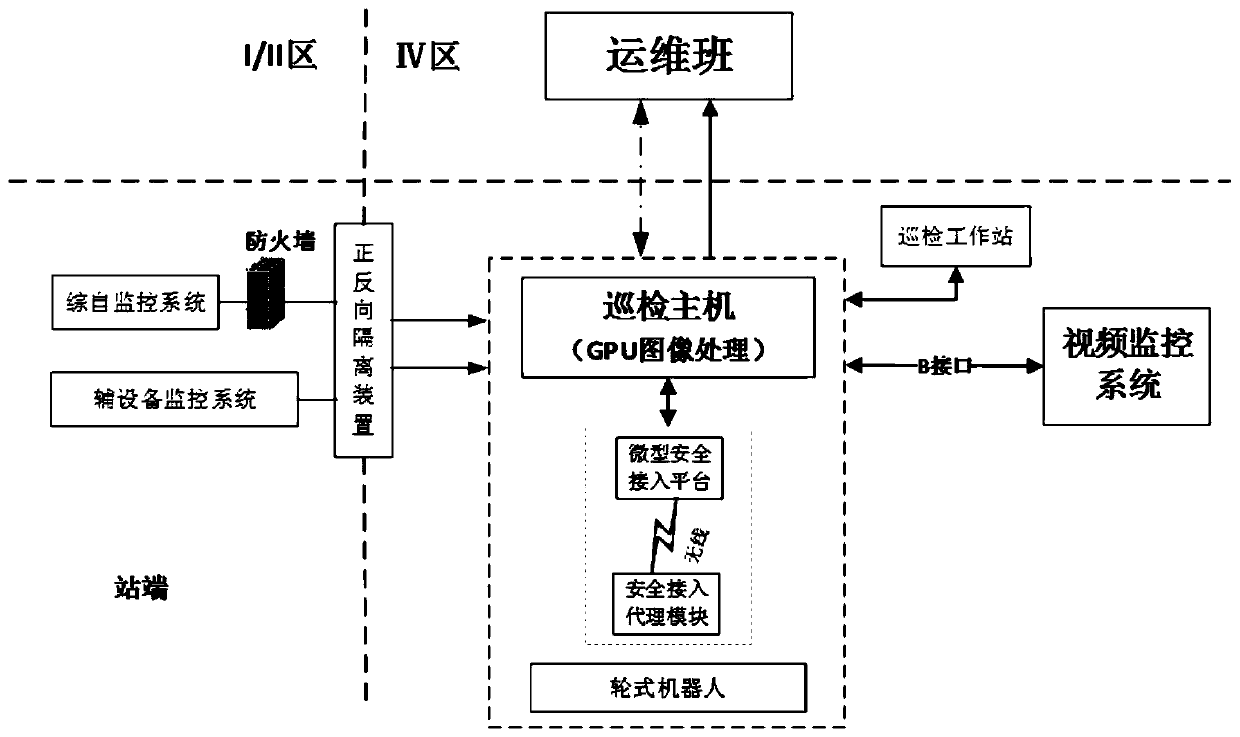

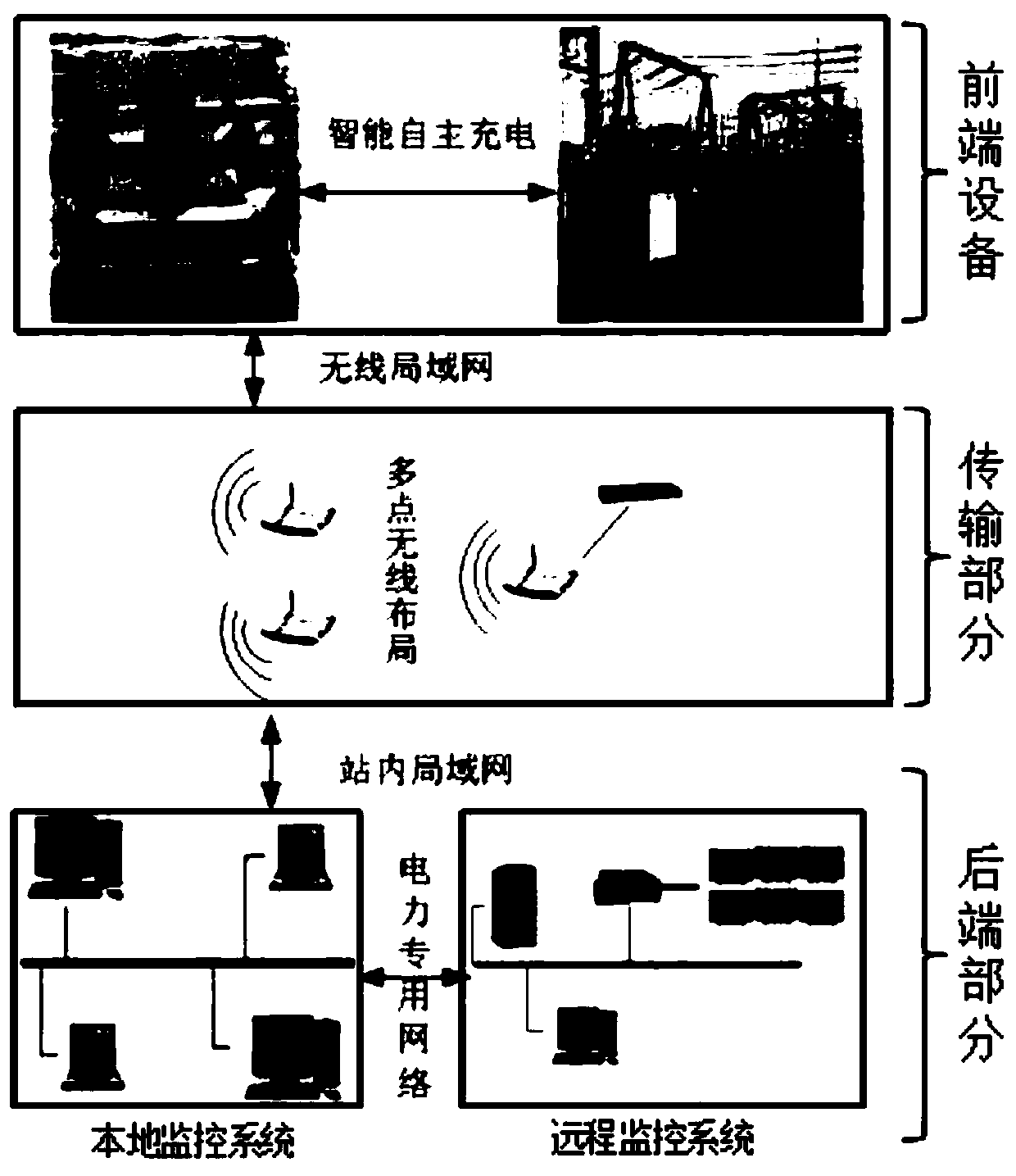

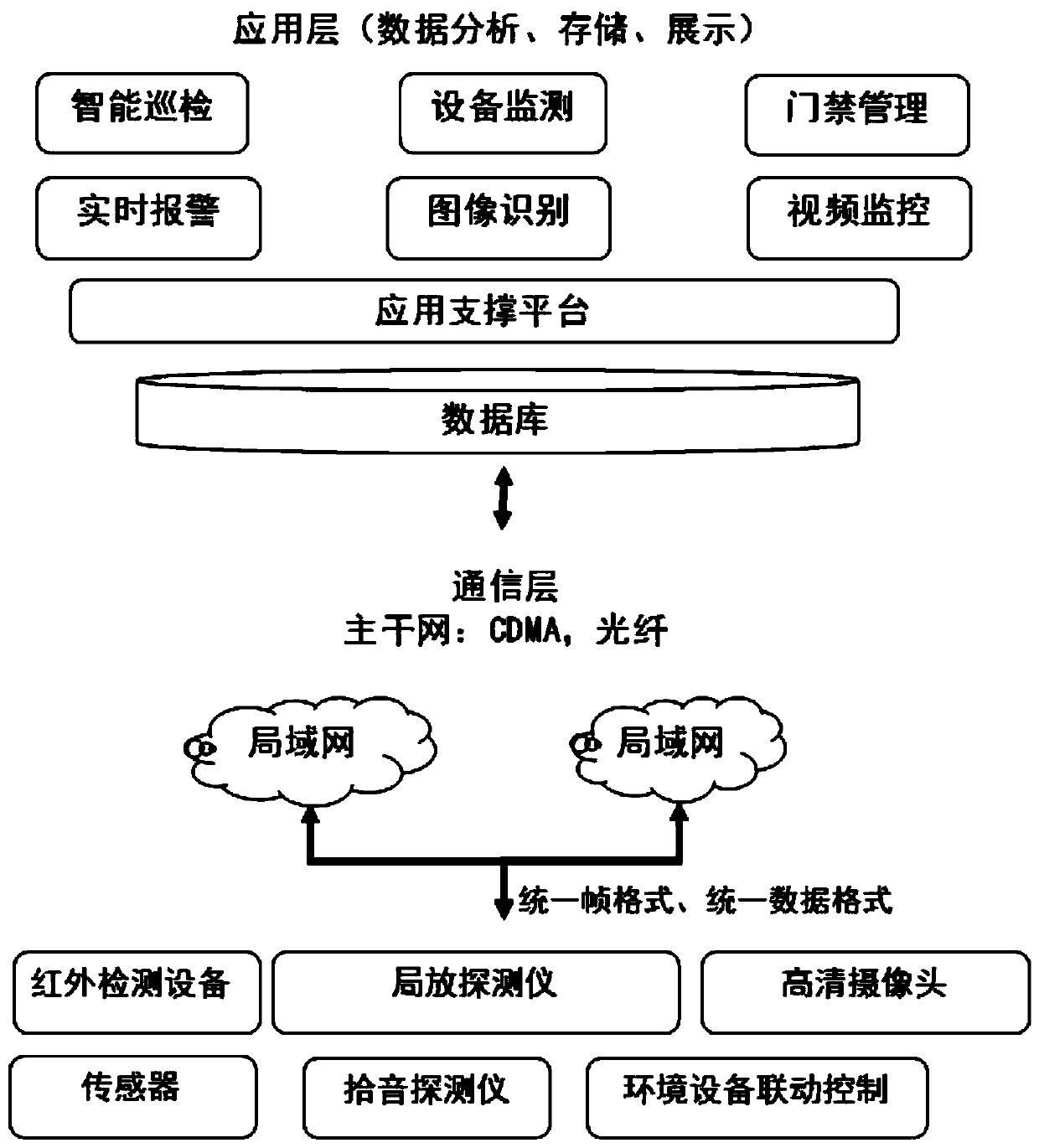

[0035] Such as Figure 1-Figure 10 As shown, the present invention arranges video surveillance devices and wheeled inspection robots in substations to build an intelligent substation operation and maintenance management platform. Realize intelligent access control, security area division, intelligent detection of equipment status, real-time transmission of accident information, environmental monitoring, defect management and other functions. It can reduce the work intensity of the on-site monitoring and inspection of the transportation inspection personnel, enable the relatively reduced operation and maintenance personnel to manage and control the increasing variety of equipment, and at the same time improve the on-site work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com