Saline-alkali soil conditioner and preparation method thereof

A soil conditioner, technology for saline-alkali land, applied in soil conditioning materials, chemical instruments and methods, other chemical processes, etc., can solve the problems of reducing soil salinity and pH, etc. The effect of soil aggregate structure formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

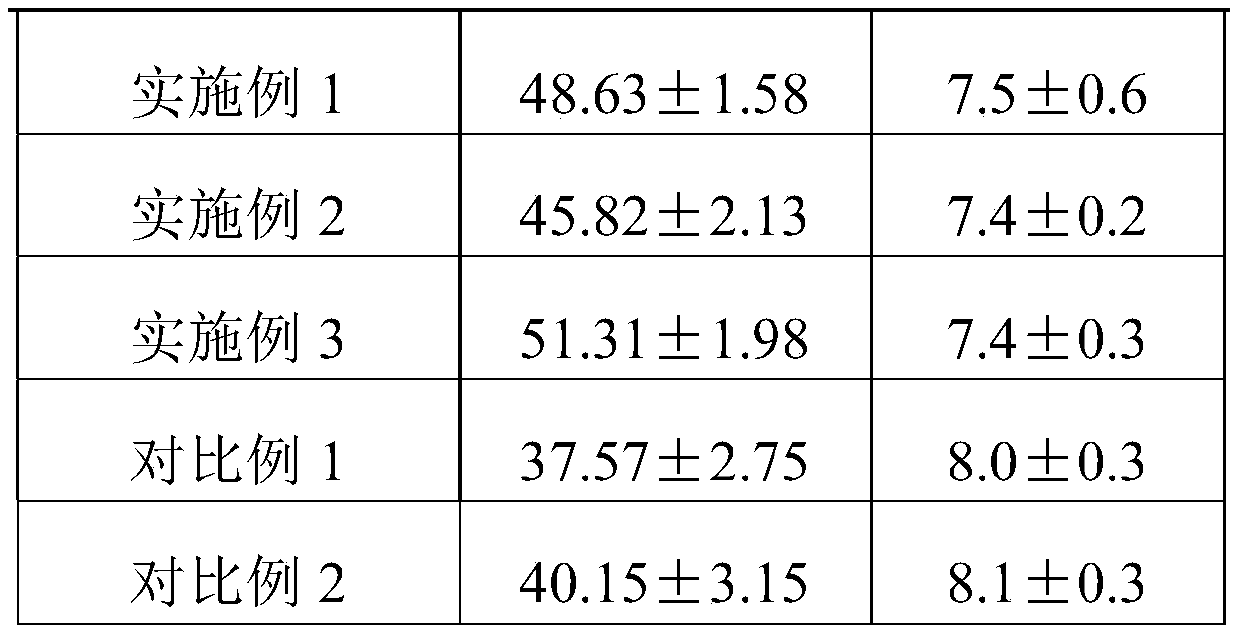

Embodiment 1

[0017] Embodiment 1 A kind of saline-alkali soil conditioner

[0018] Its preparation raw materials include by weight: 35 parts of attapulgite, 6 parts of humic acid, 4 parts of malic acid, 5 parts of manganese sulfate, 8 parts of azelaic acid, 1 part of sodium alginate, 2 parts of ammonium sulfate, hard Fatty amide 1 part.

[0019] Its preparation method comprises the following steps:

[0020] (1) Get the attapulgite and manganese sulfate of formula dosage and mix, after stirring at room temperature for 25 minutes, stir to obtain mixture A;

[0021] (2) Mix the remaining raw materials of the formula, heat to 63°C, stir for 2 hours, and cool to room temperature to obtain mixture B;

[0022] (3) Heat mixture A and mixture B obtained in step (1) to 45° C., stir for 1 hour, and cool to room temperature to obtain the saline-alkali soil conditioner.

Embodiment 2

[0023] Embodiment 2 A kind of saline-alkali soil conditioner

[0024] The raw materials for its preparation include, in parts by weight, 40 parts of attapulgite, 11 parts of humic acid, 7 parts of malic acid, 10 parts of manganese sulfate, 16 parts of azelaic acid, 3 parts of sodium alginate, 6 parts of ammonium sulfate, hard Fatty amide 3 parts.

[0025] Its preparation method comprises the following steps:

[0026] (1) Get the attapulgite and manganese sulfate of formula dosage and mix, after stirring at room temperature for 30 minutes, stir to obtain mixture A;

[0027] (2) Mix the remaining raw materials of the formula, heat to 71°C, stir for 3 hours, and cool to room temperature to obtain mixture B;

[0028] (3) Heat mixture A and mixture B obtained in step (1) to 55° C., stir for 2 hours, and cool to room temperature to obtain the saline-alkali soil conditioner.

Embodiment 3

[0029] Embodiment 3 A kind of saline-alkali soil conditioner

[0030] Its preparation raw materials include by weight: 38 parts of attapulgite, 9 parts of humic acid, 6 parts of malic acid, 8 parts of manganese sulfate, 11 parts of azelaic acid, 2 parts of sodium alginate, 4 parts of ammonium sulfate, hard Fatty amide 2 parts.

[0031] Its preparation method comprises the following steps:

[0032] (1) Take the attapulgite and manganese sulfate of formula dosage and mix, after stirring at room temperature for 28 minutes, stir to obtain mixture A;

[0033] (2) Mix the remaining raw materials of the formula, heat to 68°C, stir for 2.5 hours, and cool to room temperature to obtain mixture B;

[0034] (3) Heat mixture A and mixture B obtained in step (1) to 50° C., stir for 1.5 hours, and cool to room temperature to obtain the saline-alkali soil conditioner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com