Wave maker for submarine landslide physical model test and working method

A landslide physical model and wave-making technology, which are applied in teaching models, fluid dynamics tests, educational appliances, etc., can solve the problems of inability to meet the complex and changeable test conditions of the seabed environment, poor applicability of wave-making equipment, etc. Wave-making demand and the effect of improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

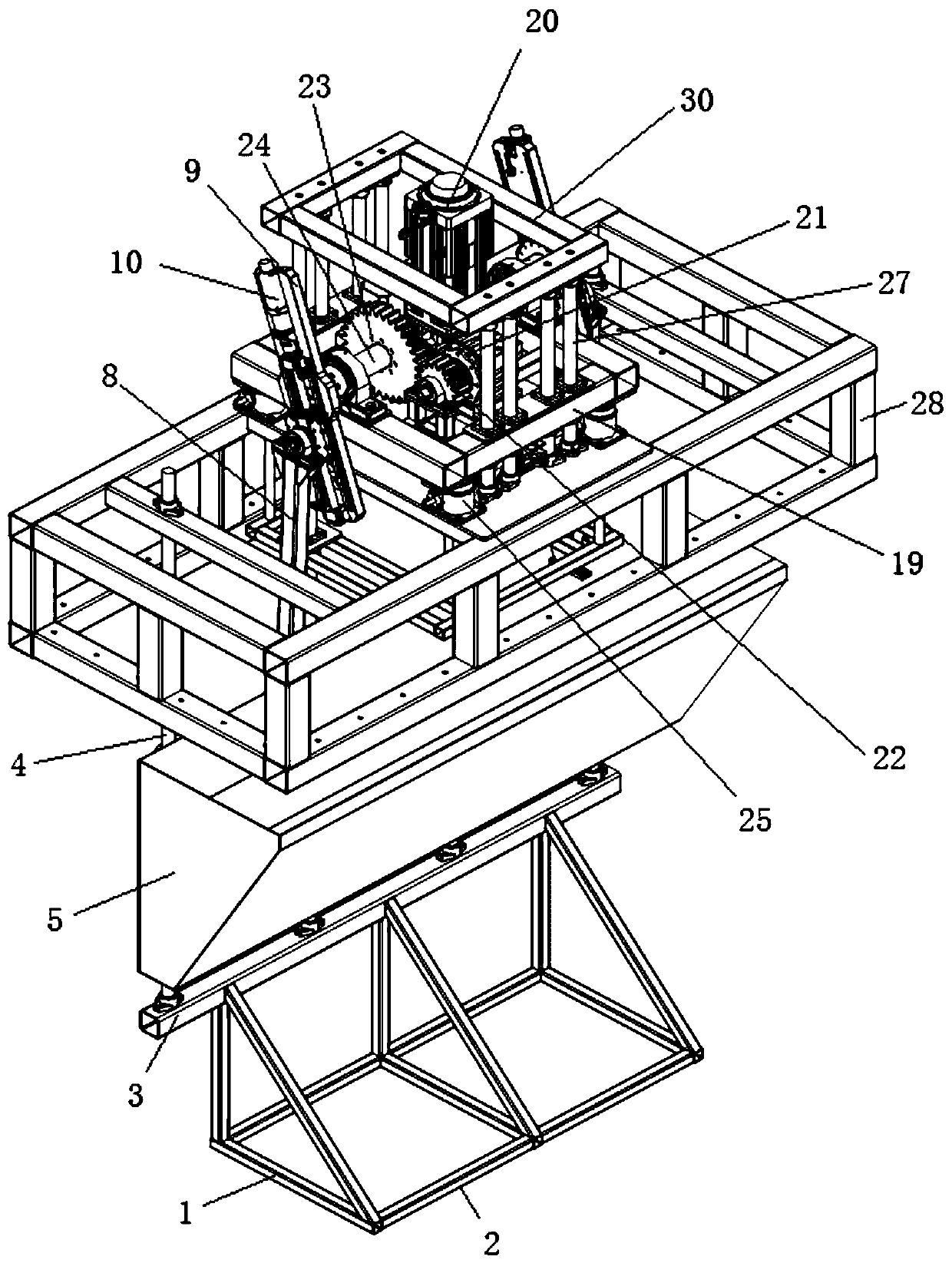

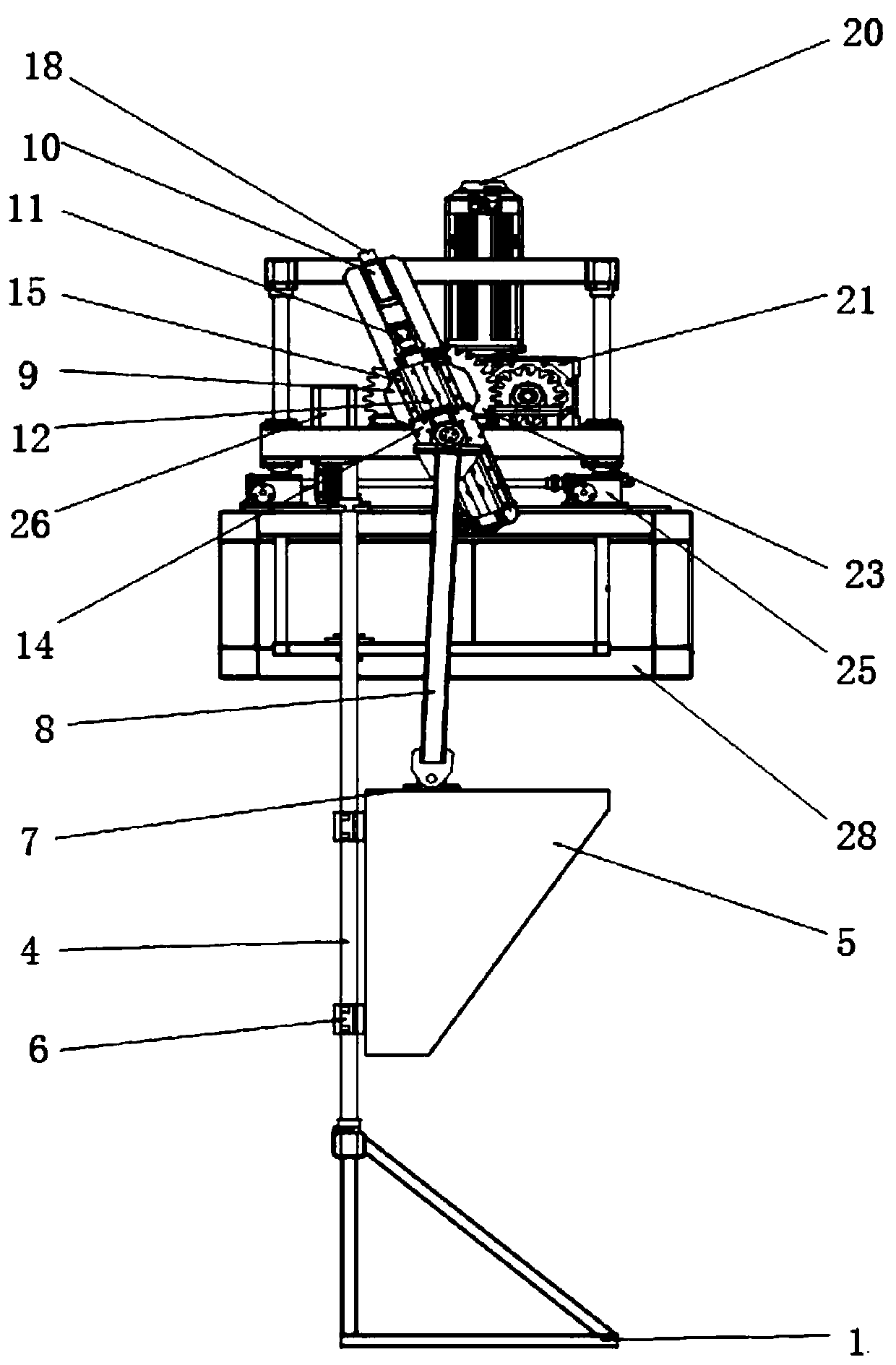

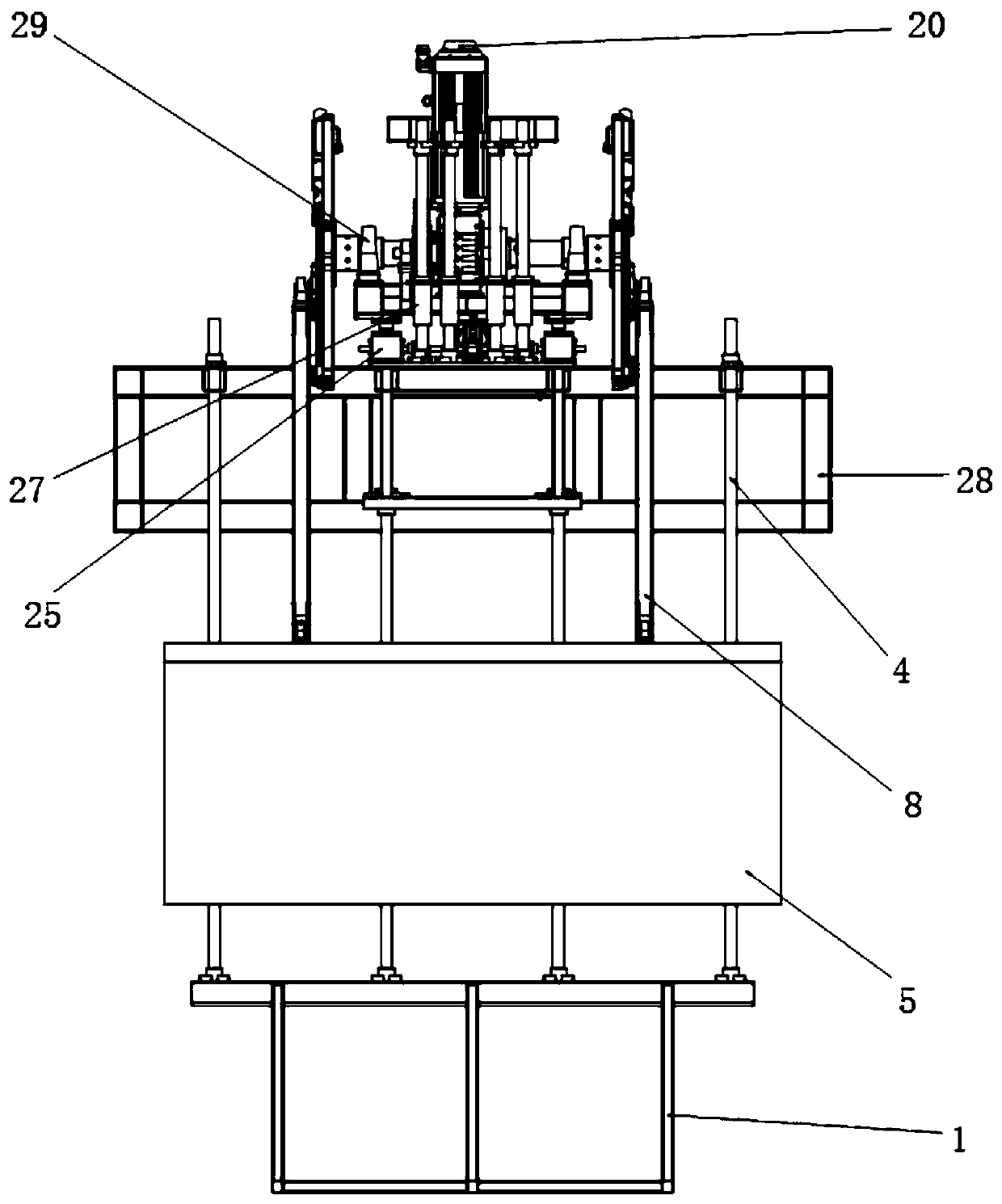

Method used

Image

Examples

Embodiment 2

[0046] This embodiment discloses a working method of a wave-making machine used for a physical model test of a submarine landslide. The lifting motor works to make the wave-making box completely enter the water, and the host computer is used to set the rotation speed of the rotating motor, and the luffing motor works. Move the luffing slider to the set position of the swing arm, and use the electronic brake to lock it. The control system sends instructions to the speed motor, and the speed motor drives the swing arm to rotate. Under the action of the connecting rod, the wave-making water tank is in the water. Doing reciprocating lifting motion, the side wall of the box inclined at an acute angle with the horizontal plane generates thrust on the water to form waves.

[0047] In this embodiment, changing the position of the amplitude modulation slider on the swing arm can adjust the motion amplitude of the wave-making water tank, thereby meeting the manufacturing requirements of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com