Zr-Sr composite microalloying and Mn-Zn alloying high-strength and high-toughness Al-Si-Cu system cast aluminum alloy and preparation method

A casting aluminum alloy and micro-alloying technology, which is applied in the field of aluminum alloy materials, can solve the problems of reducing alloy casting performance, plasticity, and low toughness, and achieve the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

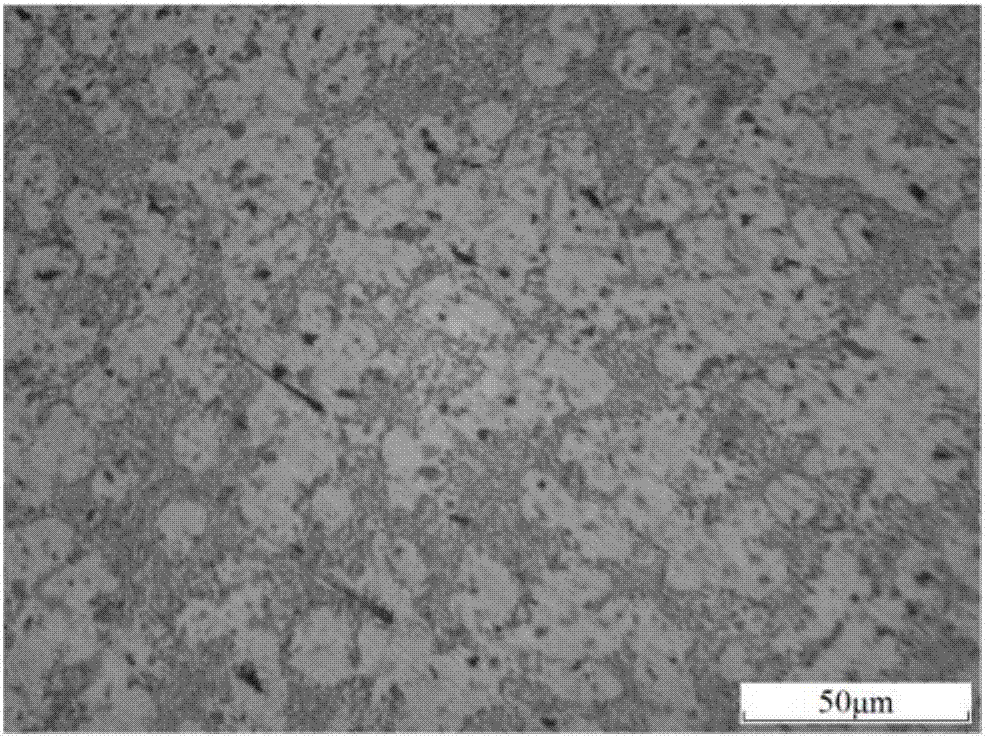

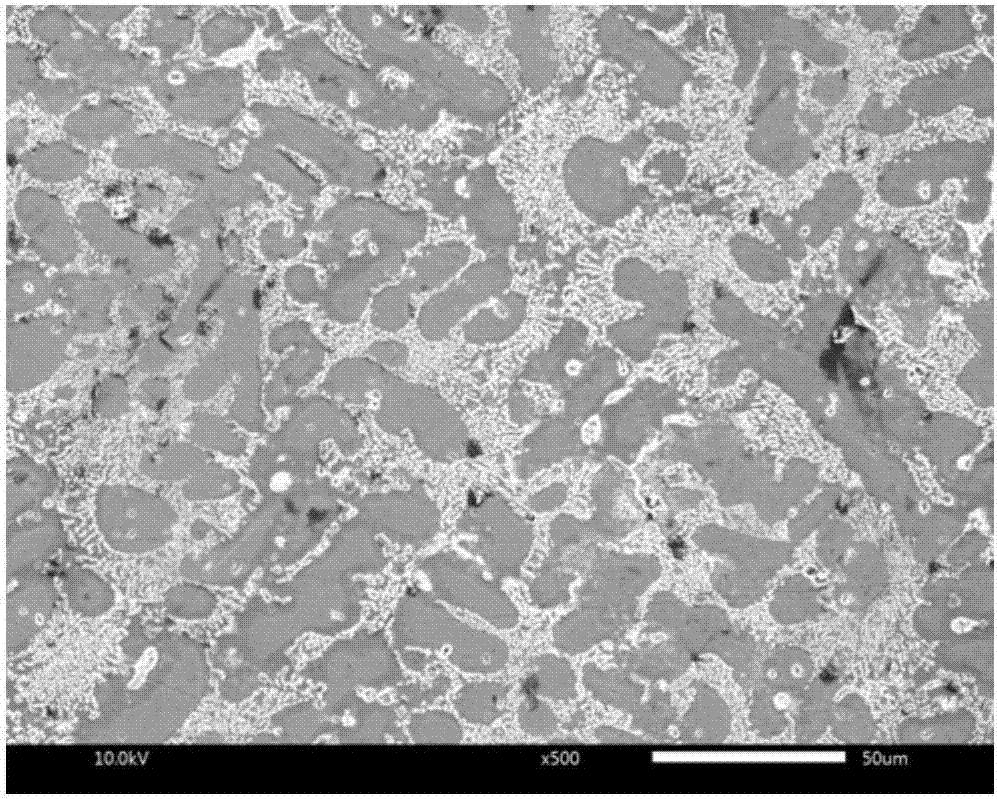

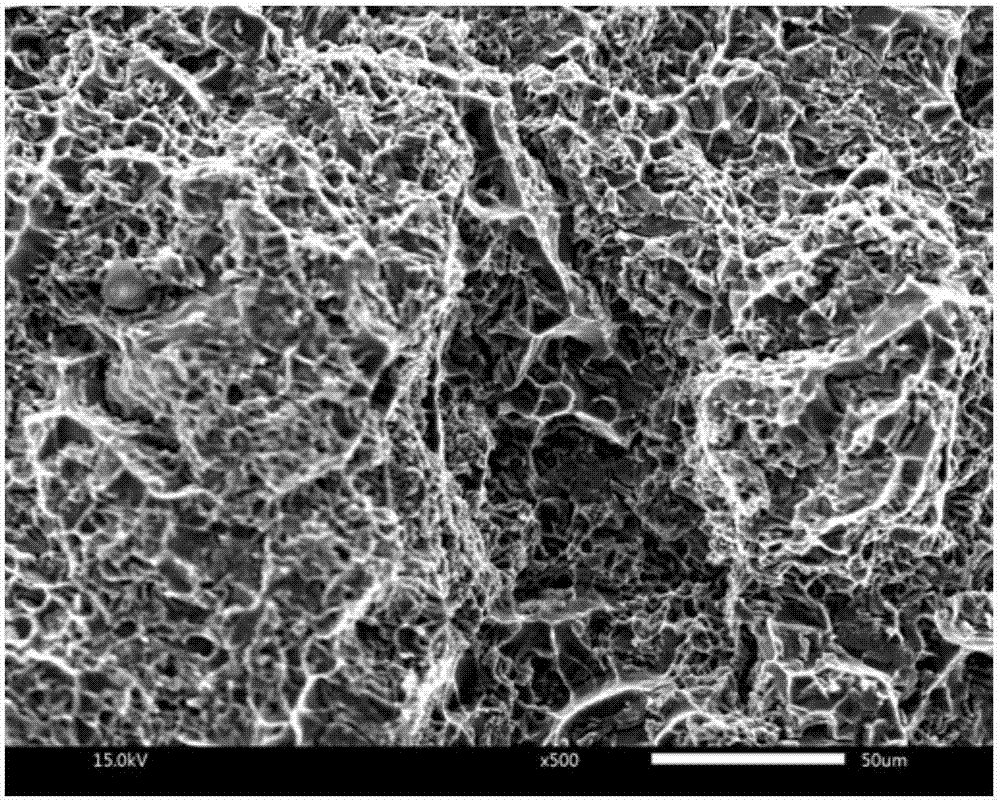

[0032] Such as figure 1 , 2 , 3, 4, and 5.

[0033]A kind of Zr, Sr composite microalloying and Mn, Zn alloying high strength and toughness Al-Si-Cu series casting aluminum alloy, its preparation method:

[0034] First A00 grade pure Al (99.79%Al, 0.14%Fe, 0.04%Si) and Al-Si (89.62%Al, 10.21%Si, 0.17%Fe, all components of the present invention are represented by mass percentage, the technical Personnel can obtain the corresponding weight parts through conventional planning, the same below, where the components added up to less than 100% are impurities) the master alloy is melted and heated to 850±10°C, and then Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy, Al-Mn(89.73%Al, 10.02%Mn, 0.19%Fe, 0.06%Si ) master alloy, Al-Zr (95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si ) master alloy and Al-Sr (89.86%Al, 9.89%Sr, 0.15%Fe, 0.10%Si ) master alloy, add 1.04% pure Zn after melting the added master alloy and pure Al; After all the master alloys and metals are melted, adjust th...

Embodiment 2

[0038] A kind of Zr, Sr composite microalloying and Mn, Zn alloying high strength and toughness Al-Si-Cu series casting aluminum alloy, its preparation method:

[0039] First A00 grade pure Al (99.79%Al, 0.14%Fe, 0.04%Si) and Al-Si (89.62%Al, 10.21%Si, 0.17%Fe, all components of the present invention are expressed in mass percentage, the same below, All the components added up to less than 100% are impurities) the master alloy is melted and heated to 850±10°C, and then Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy is added in sequence , Al-Mn (89.73%Al, 10.02%Mn, 0.19%Fe, 0.06%Si ) master alloy, Al-Zr (95.69%Al, 4.11%Zr,0.20%Fe, 0.10%Si ) master alloy and Al-Sr (89.86%Al, 9.89%Sr, 0.15%Fe, 0.10%Si ) master alloy, add 1.04% pure Zn after the master alloy and pure Al are melted; after all master alloys and metals are melted, adjust the temperature to 750± 10°C, add hexachloroethane for refining and degassing until no gas escapes, let it stand for 5-10 minutes, remo...

Embodiment 3

[0043] A kind of Zr, Sr composite microalloying and Mn, Zn alloying high strength and toughness Al-Si-Cu series casting aluminum alloy, its preparation method:

[0044] First A00 grade pure Al (99.79%Al, 0.14%Fe, 0.04%Si) and Al-Si (89.62%Al, 10.21%Si, 0.17%Fe, all components of the present invention are expressed in mass percentage, the same below, All the components added up to less than 100% are impurities) the master alloy is melted and heated to 850±10°C, and then Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy is added in sequence , Al-Mn (89.73%Al, 10.02%Mn, 0.19%Fe, 0.06%Si ) master alloy, Al-Zr (95.69%Al, 4.11%Zr,0.20%Fe, 0.10%Si ) master alloy and Al-Sr (89.86%Al, 9.89%Sr, 0.15%Fe, 0.10%Si ) master alloy, add 1.05% pure Zn after the master alloy and pure Al are melted; after all master alloys and metals are melted, adjust the temperature to 750± 10°C, add hexachloroethane for refining and degassing until no gas escapes, let it stand for 5-10 minutes, remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com