Laser welding tool and welding forming method for thin-wall components

A thin-walled component and laser welding technology, which is applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of high cost, complicated process, and large deformation of thin-walled components, and achieve improved material utilization and good process quality , The effect of small welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

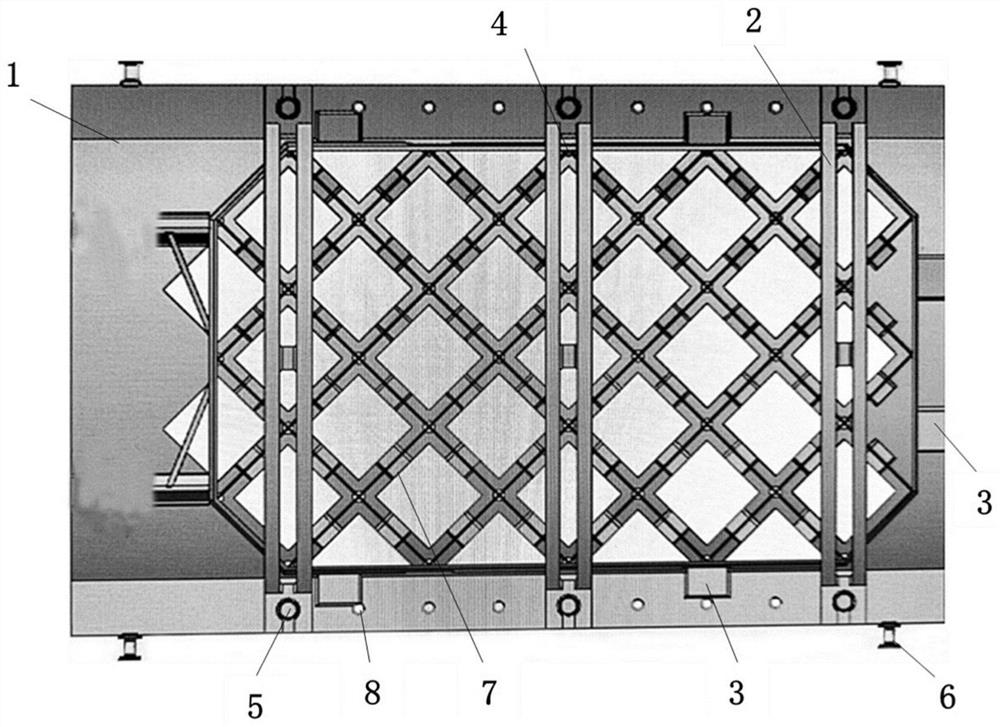

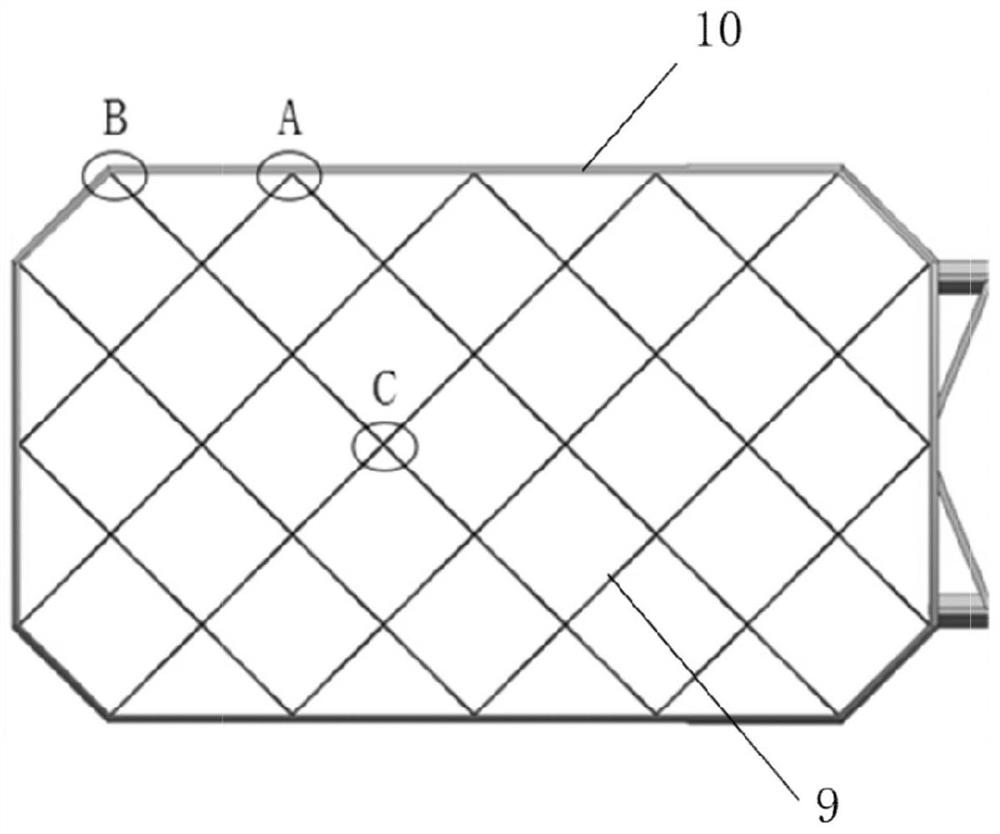

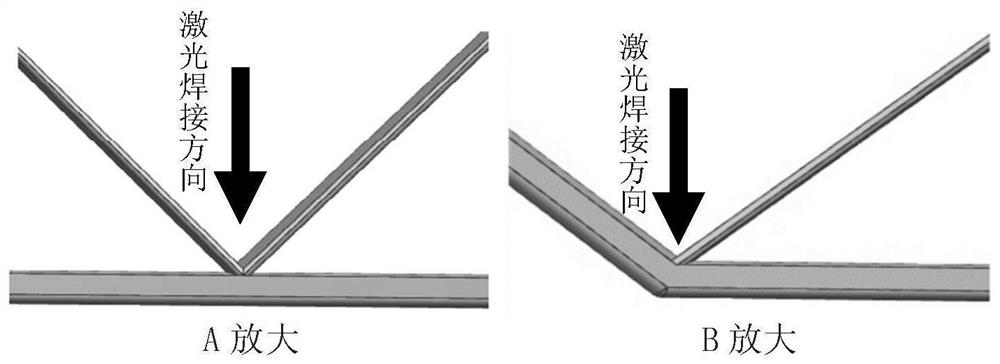

[0067] combine figure 1 , a laser welding tool for thin-walled components, which includes a profiling plate 1, a compression strip assembly 2 and a limit block 3;

[0068] The profiling plate 1 is used as the main support body when the workpiece is assembled and welded, and its shape is consistent with the shape of the thin-walled member to be welded. The shape of the thin-walled member is arc-shaped, and the inner wing plate is spiral and has a grid structure;

[0069] The plurality of compression strip assemblies 2 are arranged on the profile plate 1 to prevent the workpiece from loosening or slipping after assembly, and to control the assembly steps of the parts well;

[0070] The limiting block 3 is arranged on the profiling plate 1, and is used to limit the workpiece during welding and prevent the workpiece from being deformed during welding.

[0071] The limit block 3 limits the inside and outside of the frame of the thin-walled member, and plays the role of assembling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com